Modular wave filter

A modular and filter technology, applied in the field of filters, can solve the problems of long completion cycle, long processing cycle and complex completion process, and achieve the effect of saving time, processing cost and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

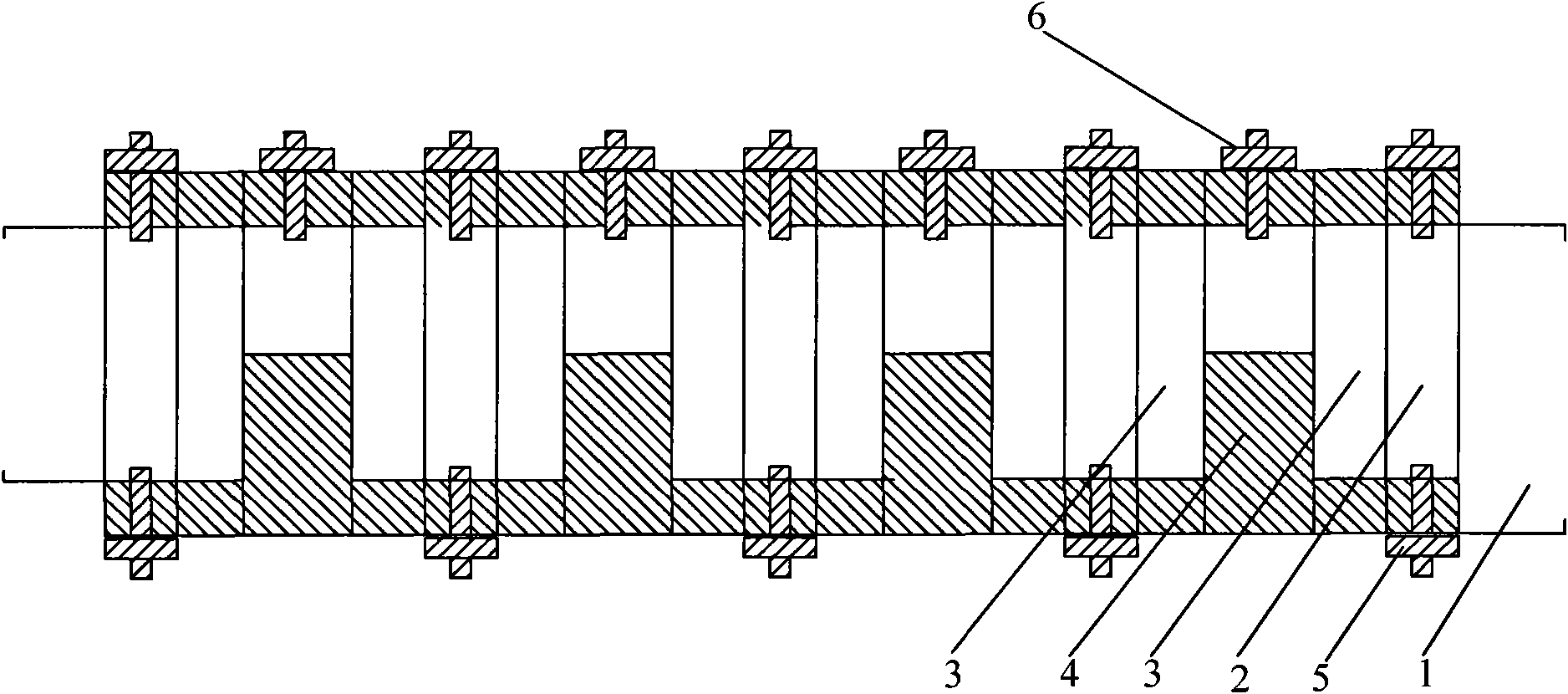

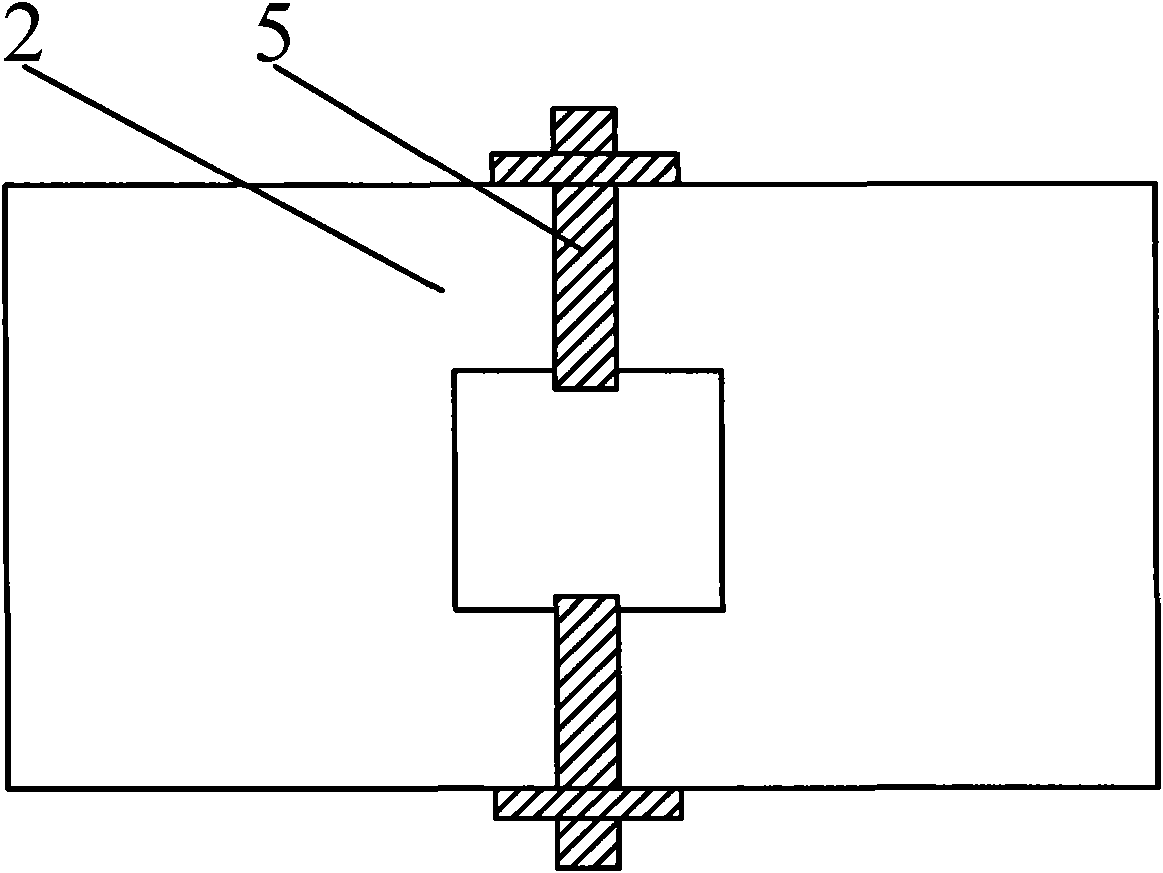

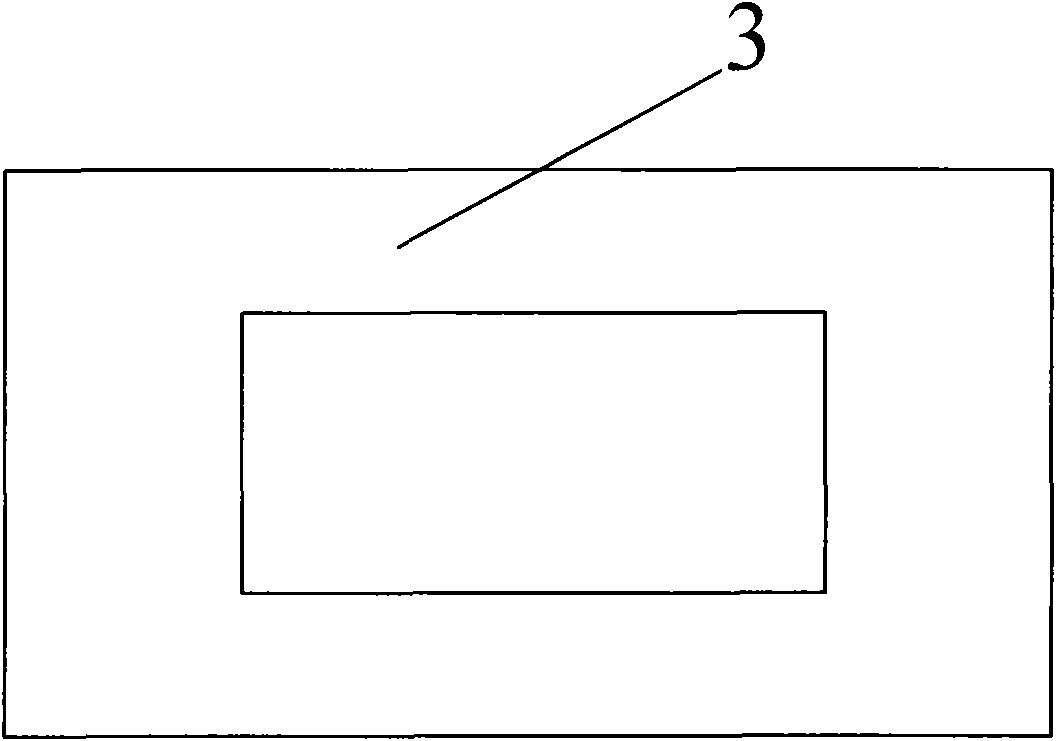

[0015] Such as Figure 1 ~ Figure 4 As shown, the modular filter includes two input and output structures 1, five coupling metal sheets 2, eight waveguide metal sheets 3 and four resonant metal sheets 4, and coupling tuning screws 5 on the coupling metal sheets 2, And the resonance tuning screw 6 located on the resonance metal sheet 4. The coupling metal sheet 2, the waveguide metal sheet 3 and the resonant metal sheet 4 are all modular diaphragms. The two input and output structures 1 are respectively arranged at both ends of the modular filter, and are respectively connected to the inside of the modular filter through coupling metal sheets 2 . Inside the modular filter, starting from the coupling metal sheet 2 at the input end, the coupling metal sheet 2, waveguide metal sheet 3, resonant metal sheet 4, and waveguide metal sheet 3 are sequentially connected in series until the last waveguide metal sheet The slice 3 is connected to the input-output structure 1 at the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com