PWM control method for three-level LLC converter

A control method and three-level technology, which can be applied to conversion equipment with intermediate conversion to AC, regulating electrical variables, and control/regulating systems, etc., can solve the design difficulties of three-level LLC converters, large reverse recovery current, Problems such as poor reverse recovery characteristics of parasitic diodes, to achieve the effect of solving the reverse recovery problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

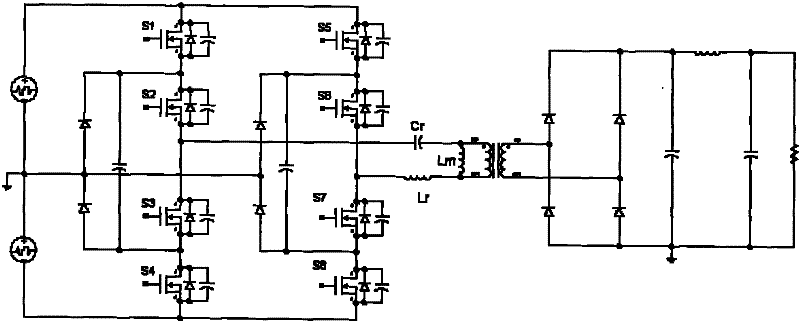

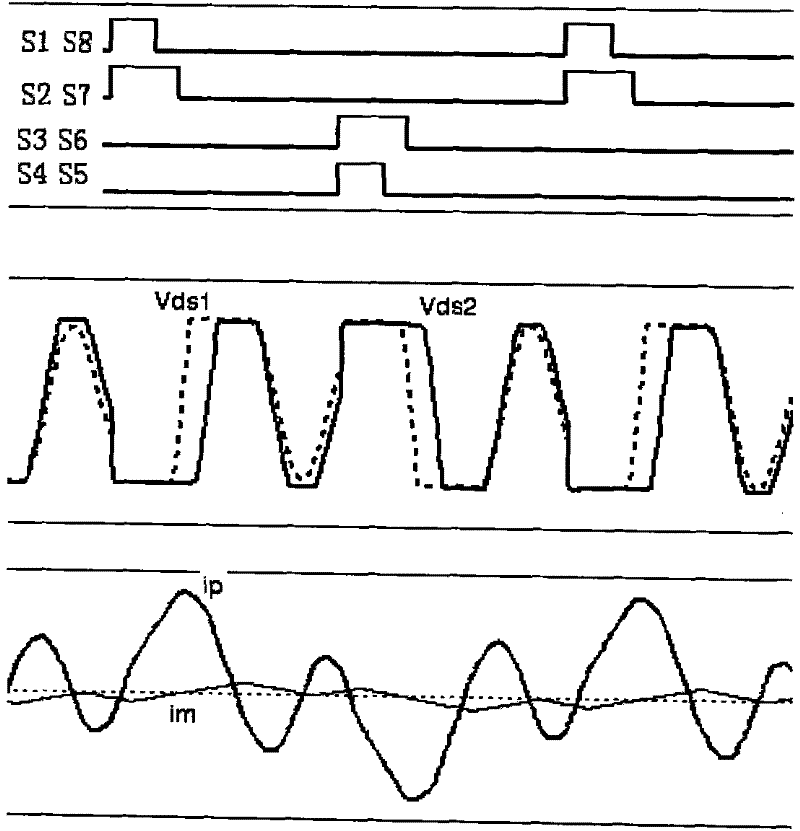

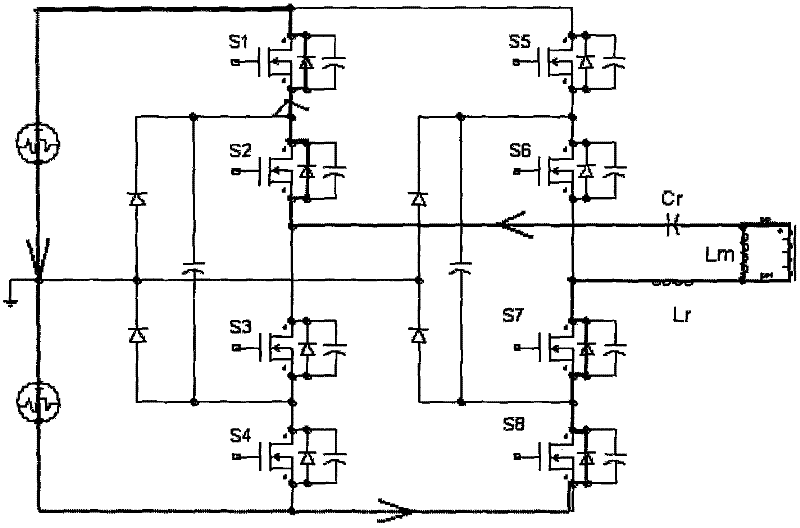

[0025] Please refer to figure 1 and Figure 7 , the PWM control method of the three-level full-bridge LLC converter of an embodiment comprises the following steps:

[0026] Step A1: For the four switching tubes S1-S4 on the first bridge arm, determine the minimum duty cycle of the inner tubes S2 and S3 in PWM mode so that the delay of the inner tubes S2 and S3 after the outer tubes S1 and S4 are turned off The length of the off time can avoid the reverse resonance of the resonant current;

[0027] Step A2: Through PWM control, adjust the duty cycle of the outer tubes S1 and S4 respectively according to the gain requirement, and keep the duty cycle of the inner tubes S2 and S3 not lower than the minimum duty cycle accordingly.

[0028] Similarly, for the second bridge arm, the above method is used to control the duty cycle of the inner tubes S6, S7 and the outer tubes S5, S8.

[0029] Since the effective duty cycle of the three-level LLC resonant converter is determined by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com