Long wall alternate type coal mining method

A coal mining method and longwall technology, applied in ground mining, mining equipment, earthwork drilling, etc., can solve the problems of large amount of coal pillars, frequent relocation, waste of coal resources, etc., and reduce the amount of coal pillars and improve the mining area. The recovery rate and the effect of saving coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A longwall interval type coal mining method is carried out in the following steps:

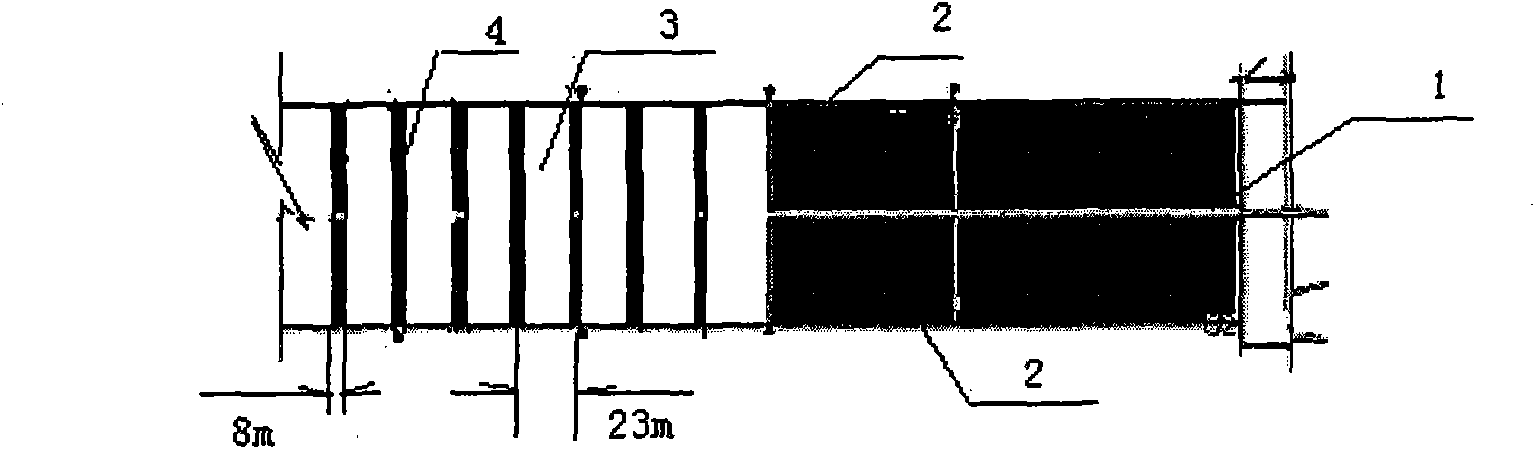

[0063] (1) Divide the working face according to the actual layout of the longwall according to the mine field mineable coal seam;

[0064] (2) Determine the width of the working face to reasonably advance the mining zone according to the coal seam occurrence conditions. The mining zone width of the working face is > 23m and < 45m ~ 60m, and a coal pillar of 6m ~ 12m is left between the previous mining zone and the next mining zone;

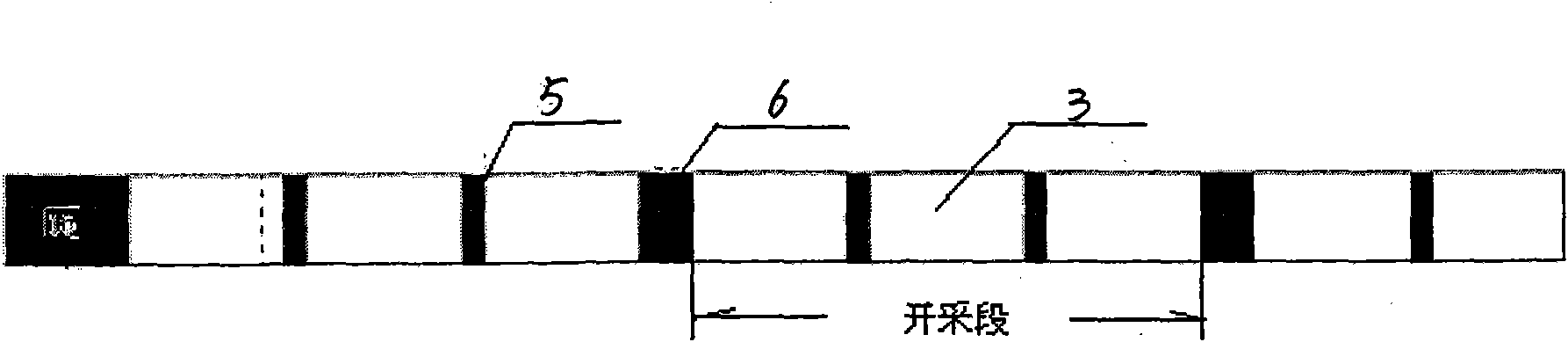

[0065] (3) Or leave a 5m-8m temporary coal pillar between the previous mining zone and the next mining zone; each mining section includes 2 to 3 mining zones, and a rigid isolation coal pillar is left between the mining section and the mining section. Coal pillar width is 12m ~ 20m;

[0066] (4) In order to reduce the load of the conveyor on the longwall working face, the longwall working face can be arranged in opposite directions, and each working face h...

Embodiment 2

[0070] A longwall interval type coal mining method is carried out in the following steps:

[0071] (1) Divide the working face according to the actual layout of the longwall according to the mine field mineable coal seam;

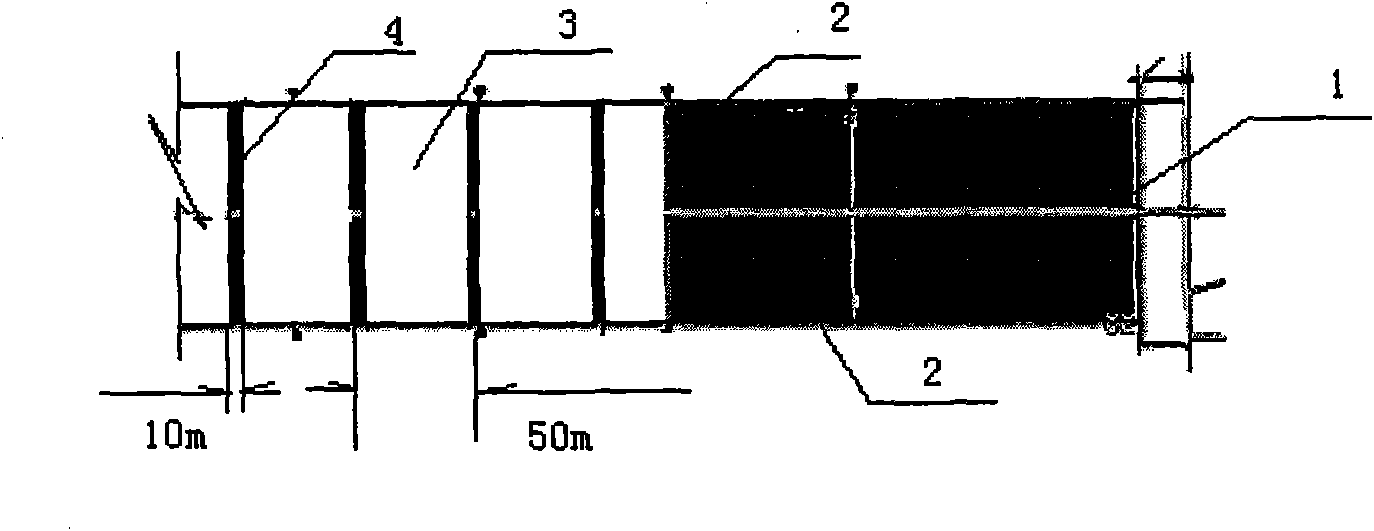

[0072] (2) Determine the width of the advancing mining zone reasonably in the working face. The advancing mining zone width of the working face is > 28m and < 48m ~ 58m, and a 7m ~ 11m coal pillar is left between the previous mining zone and the subsequent mining zone;

[0073] (3) Or leave a temporary coal pillar of 5.5m to 7.5m between the previous mining zone and the next mining zone; each mining section includes 2 to 3 mining zones, and leave a rigid isolated coal pillar between the mining section and the mining section. The width of isolated coal pillar is 13m~18m;

[0074] (4) In order to reduce the load of the conveyor on the longwall working face, the longwall working face can be arranged in opposite directions, and each working face has three para...

Embodiment 3

[0078] (1) Divide the working face according to the actual layout of the longwall according to the mine field mineable coal seam;

[0079] (2) Determine the width of the advancing mining zone reasonably in the working face. The advancing mining zone width of the working face is > 30m but < 50m ~ 55m, and 8m ~ 10m coal pillars are left between the previous mining zone and the next mining zone;

[0080] (3) Or leave a temporary coal pillar of 6m to 7m between the previous mining zone and the next mining zone; each mining section includes 2 to 3 mining zones, and a rigid isolation coal pillar is left between the mining section and the mining section. Column width is 15m ~ 16m;

[0081] (4) In order to reduce the load of the conveyor on the longwall working face, the longwall working face can be arranged in opposite directions, and each working face has three parallel grooves, the middle is the return air smooth groove, and the two sides are the air inlet smooth grooves;

[0082]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com