Air duct of uv lamp

A technology of air ducts and light boxes, which is applied in the cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc. It can solve the problems of large deformation of lamp tubes, short life, and uneven cooling of lamp tubes. To achieve the effect of increased service life, small deformation and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

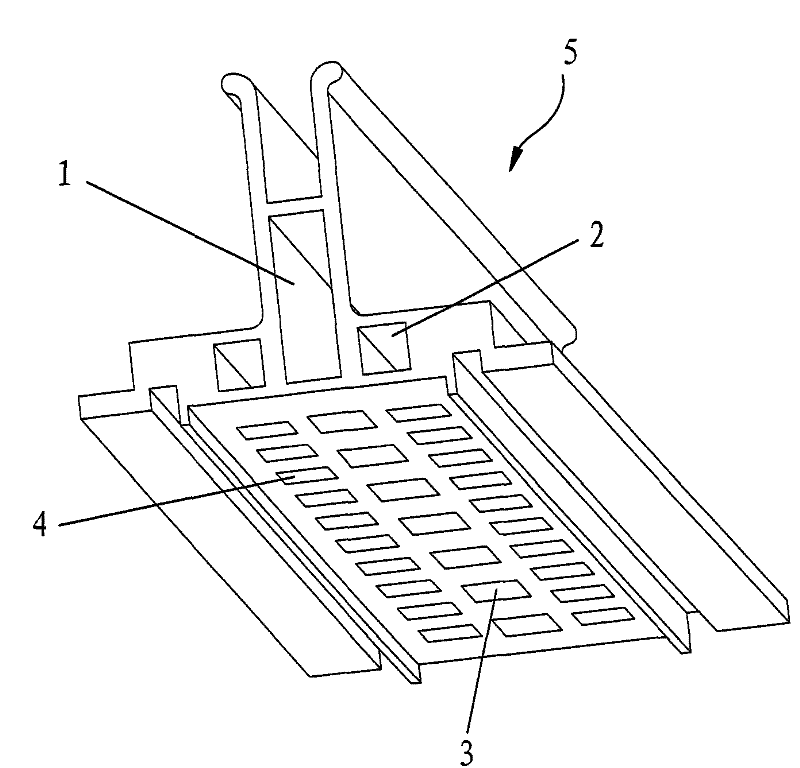

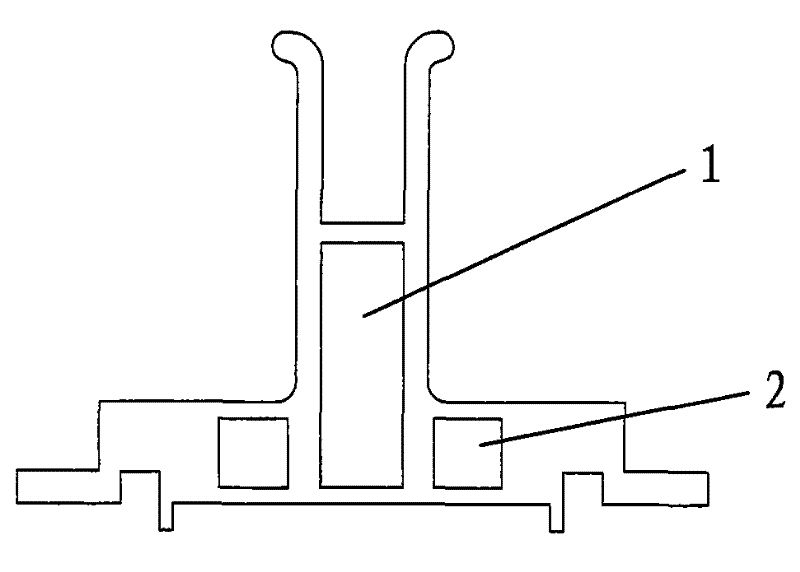

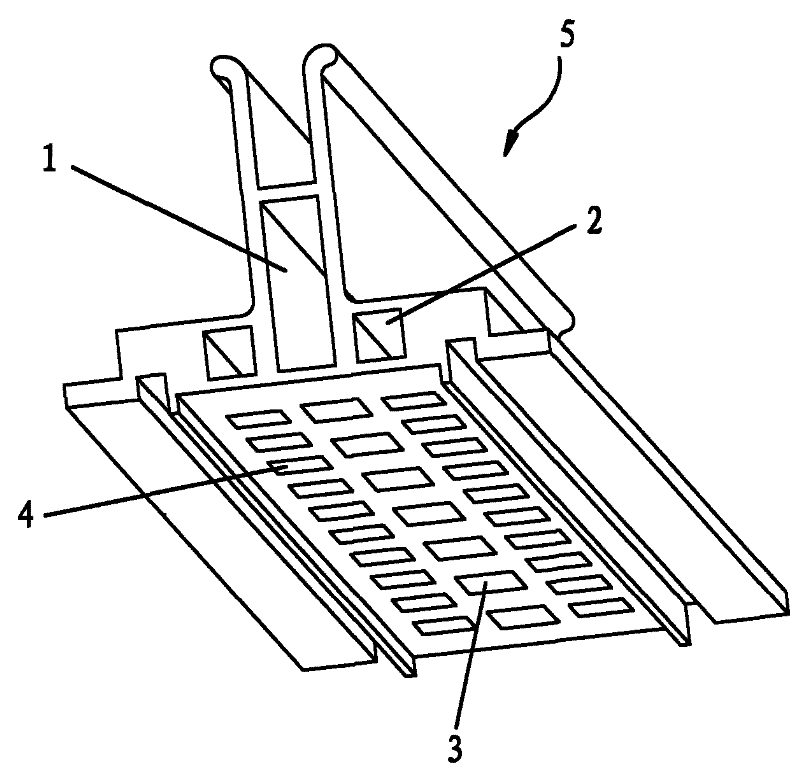

[0013] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] See attached figure 1 , attached figure 2 Shown, a kind of air channel of UV lamp, on this air channel 5 there is a first cavity 1 for sending fresh air into the lamp box, and the two sides of the first cavity 1 are also provided with respectively for discharging ozone The second chamber 2 of the exhaust gas, the first chamber 1 and the second chamber 2 extend to the entire air duct 5, and the bottoms of the first chamber 1 and the second chamber 2 are respectively provided with a row of holes connected to the air duct. The first hole 3 and the second hole 4 of the channel, and the diameter of the second hole 4 at the bottom of the second cavity 2 is smaller than the first hole 3 at the bottom of the first cavity 1 . The shape of the hole 3 in this embodiment is a square hole. In fact, the first hole 3 and the second hole 4 can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com