Dry-type slag-conveying device

A slag conveying and dry-type technology, which is applied in the field of dry slag conveying equipment, can solve the problems of fine ash residue in the slag lifting section, and achieve the effects of avoiding slag falling, saving energy, and reducing transportation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

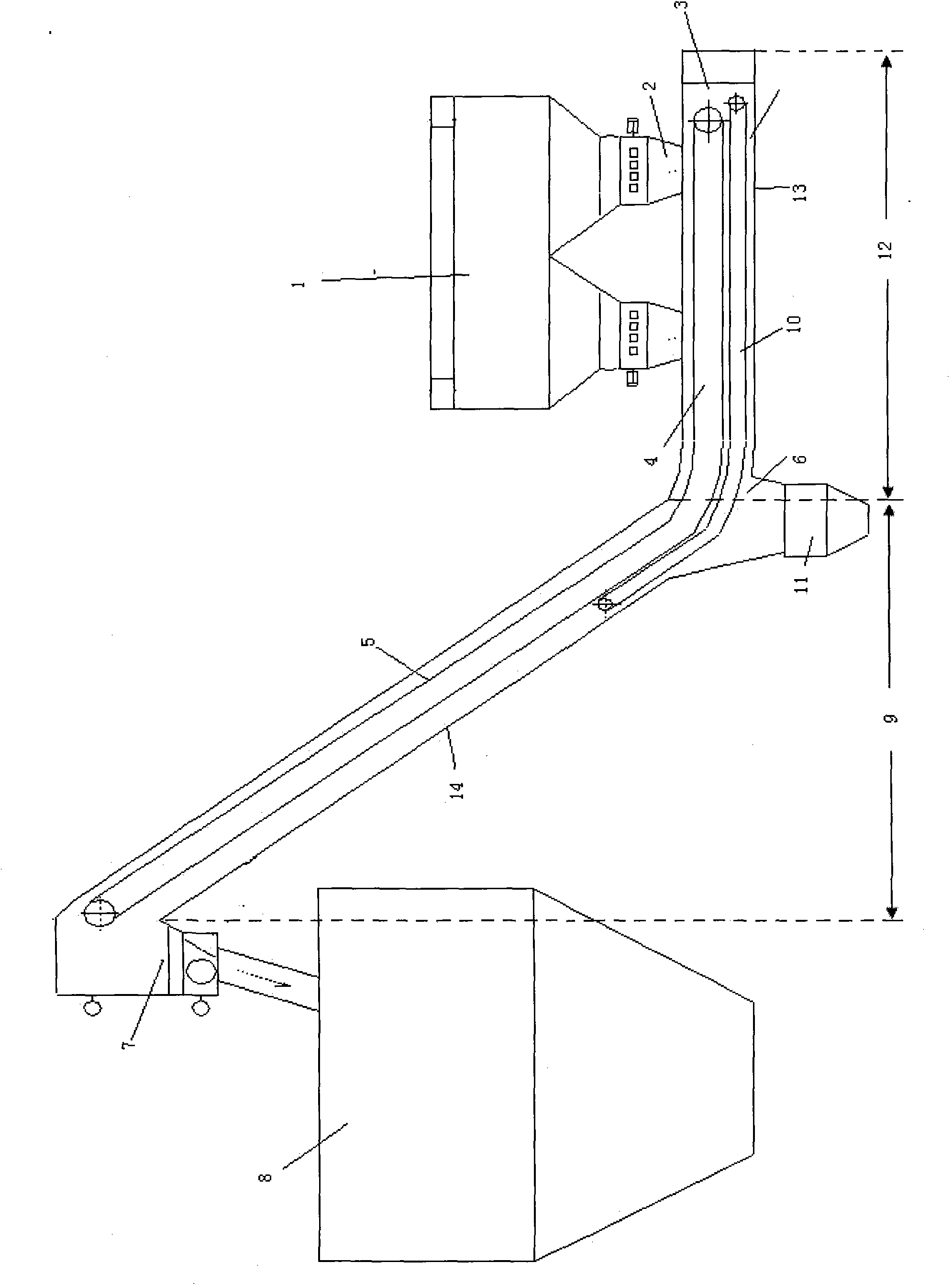

[0044] in such as figure 1 In the shown dry slag conveying equipment, the slag conveying device is a steel belt slag conveying device 4 , and the fine ash removal device is a scraper ash removing device 10 .

[0045] The above-mentioned dry slag conveying equipment includes a slag carrying box 3 and a steel belt slag conveyor 4 arranged in the slag carrying box 3; composition. The slag collection section 12 is arranged below the slag discharge port 2 of the boiler 1, and one end close to the slag discharge port 2 is closed, and the other end communicates with the slag lifting section 9, and the slag lifting section 9 is connected with the slag collection section 12 A slag outlet 7 is provided at the corresponding other end of one end, and a fine ash outlet 6 is provided at the end where the slag collecting section 12 is connected with the slag lifting section 9 . In the slag carrying box 3, and between the steel belt slag conveyor 4 and the carrying surface of the slag carry...

Embodiment 2

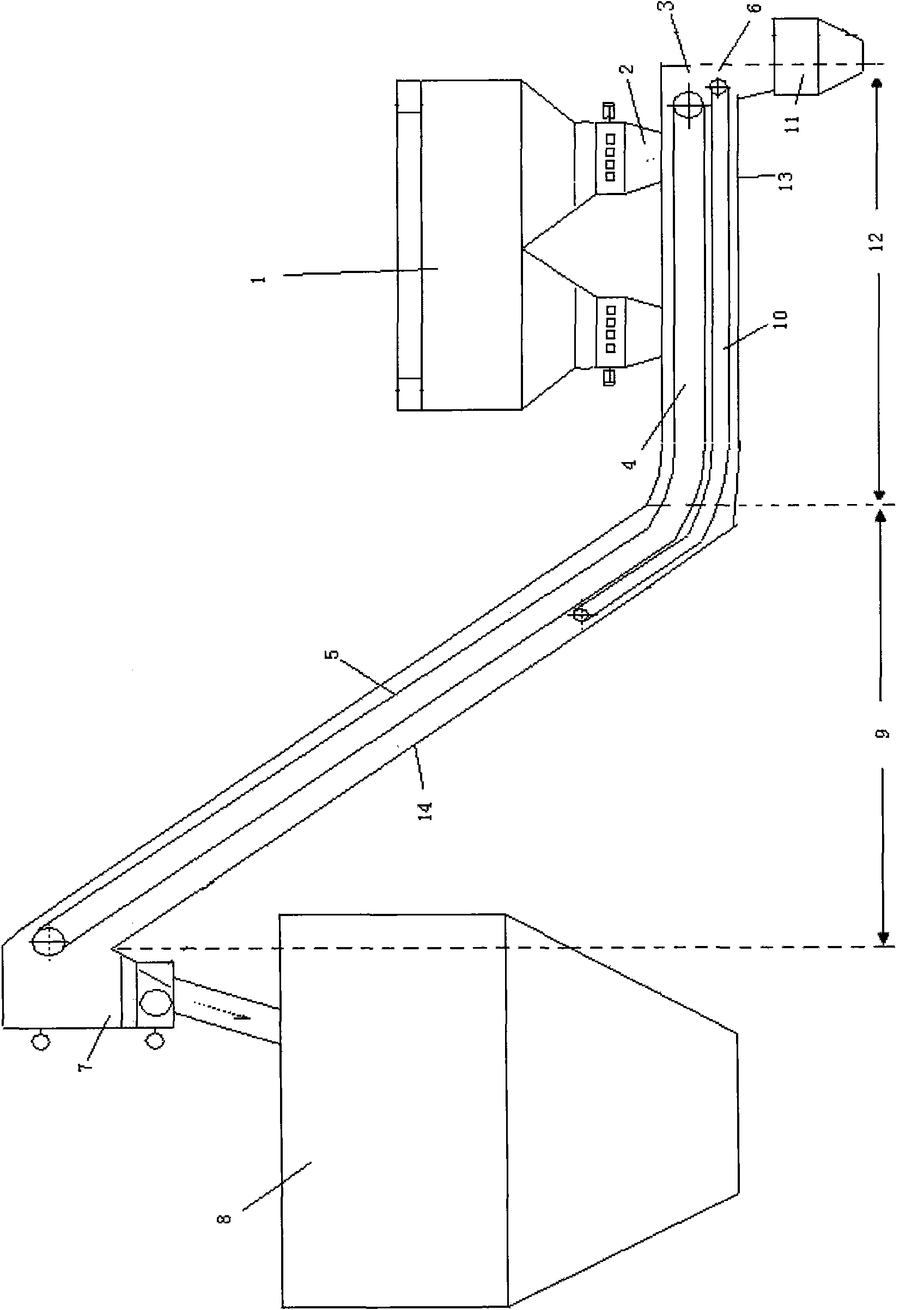

[0050] like figure 2 As shown, the difference between the dry slag conveying equipment in this embodiment and the dry slag conveying equipment in Embodiment 1 is that the fine ash outlet 6 is set in the slag collecting section 12 close to the slag outlet 2 of the boiler 1 At one end, the scraper ash removal device 10 moves toward the fine ash outlet 6, and the fine ash can be discharged through the fine ash outlet 6 into the mixing bin 11 provided at the fine ash outlet 6.

[0051] In addition to the structures described in the above two embodiments, the dry slag conveying equipment described in the present invention can also be modified so that both ends of the slag collection section 12 mentioned in Embodiment 1 and Embodiment 2 are simultaneously provided with There are fine ash outlets 6, and the scraper ash removal device moves towards at least one of the fine ash outlets.

[0052] The two ends of the slag collection section of the slag carrying box are provided with fi...

Embodiment 3

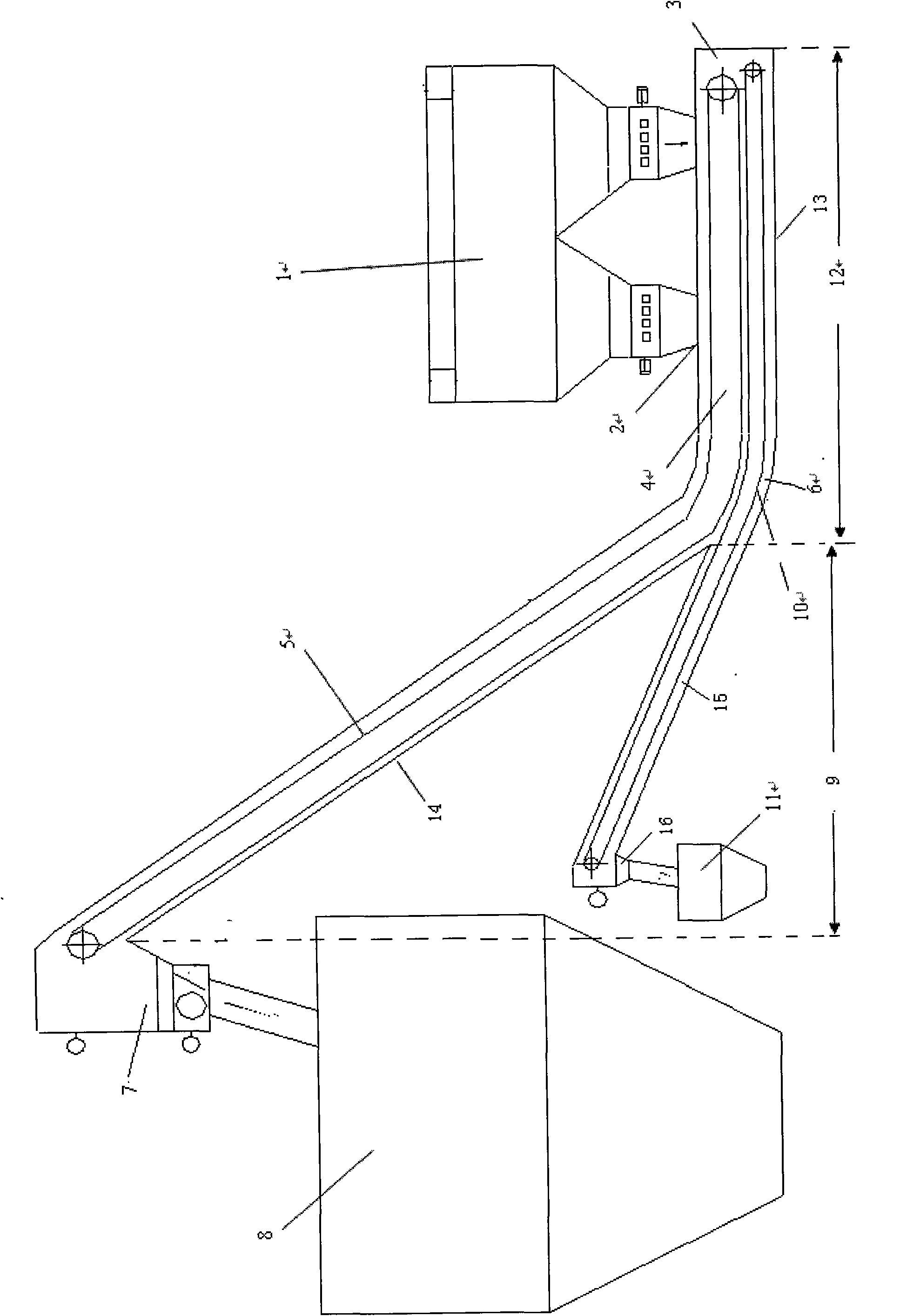

[0054] like image 3 The shown dry slag conveying equipment includes a slag carrying box 3 and a steel belt slag conveyor 4 installed in the slag carrying box 3; wherein, the slag carrying box 3 is lifted by the slag collecting section 12 and the slag Segment 9 is composed. The slag collection section 12 is arranged below the slag discharge port 2 of the boiler 1, and one end close to the slag discharge port 2 is closed, and the other end communicates with the slag lifting section 9, and the slag lifting section 9 is connected with the slag collection section 12 A slag outlet 7 is provided at the corresponding other end of one end, and a fine ash outlet 6 is provided at the end where the slag collecting section 12 is connected with the slag lifting section 9 . In the dry slag conveying equipment, there is also an extension box 15 with one end connected to the slag collection section 12 through the fine ash outlet 6, and the other end of the extension box 15 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com