Intelligent fault diagnosis method for gear box

A technology of intelligent diagnosis and gearbox, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of limited effect of spectrum analysis and diagnosis, limited application of intelligent diagnosis, low accuracy of intelligent diagnosis, etc., so as to improve the success rate of fault diagnosis and improve the Maintenance efficiency and man-hour saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

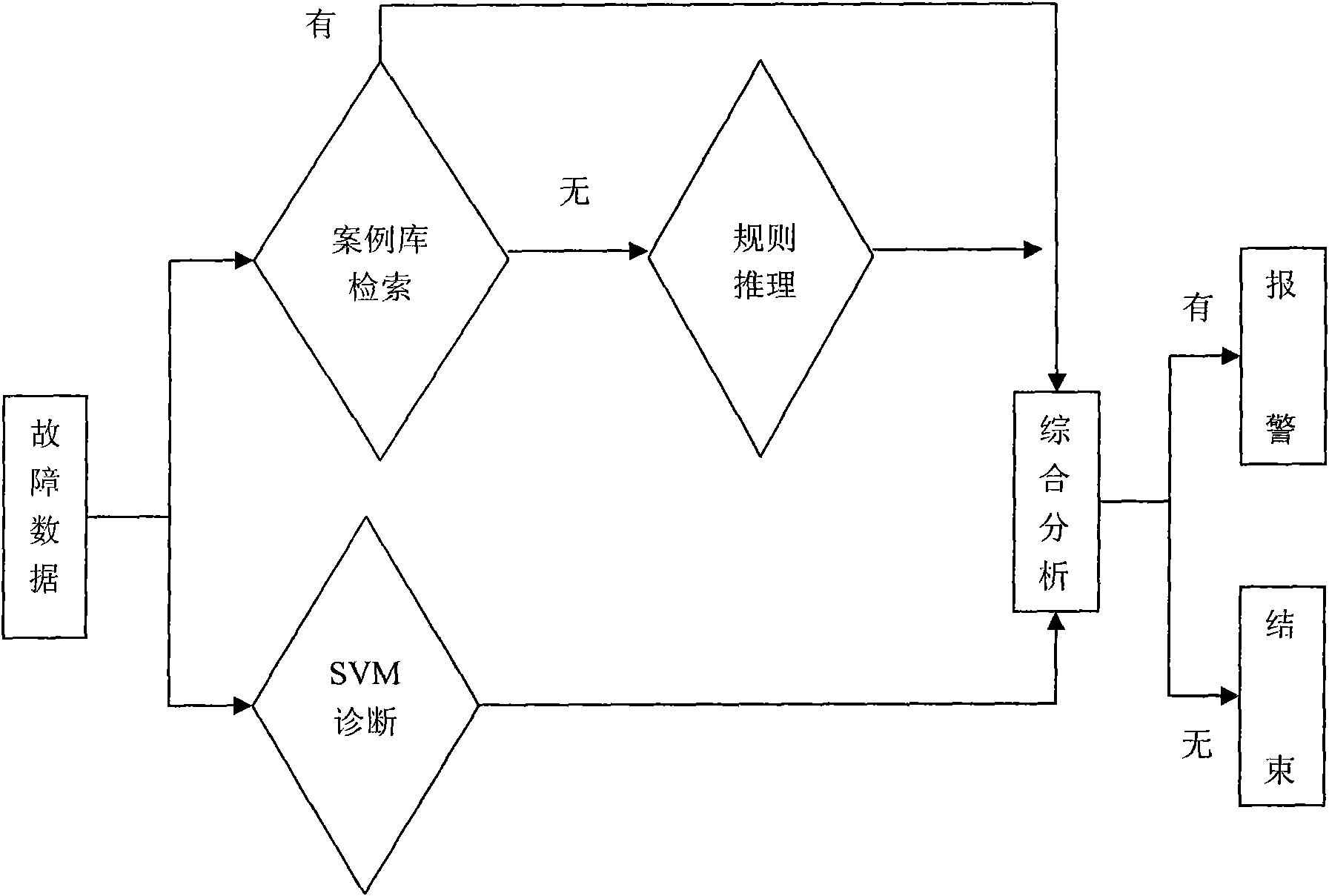

[0035] Such as figure 1 As shown, the embodiment of the method of the present invention is used for intelligent diagnosis of gearbox faults.

[0036] Embodiments of the method of the present invention include:

[0037] Step 1, the step of detecting and making a judgment;

[0038] The result of the judgment is that there is a potential failure or no potential failure;

[0039] Step 2 is to make the following choices based on the judgment result of Step 1:

[0040] The judgment result of step 1 contains potential failures, and an early warning is issued;

[0041] In the judgment result of step 1, there is no hidden trouble, end;

[0042] The step 1 at least includes: a step of case reasoning and making judgment, a step of rule reasoning and making judgment, a step of support vector machine training and judgment;

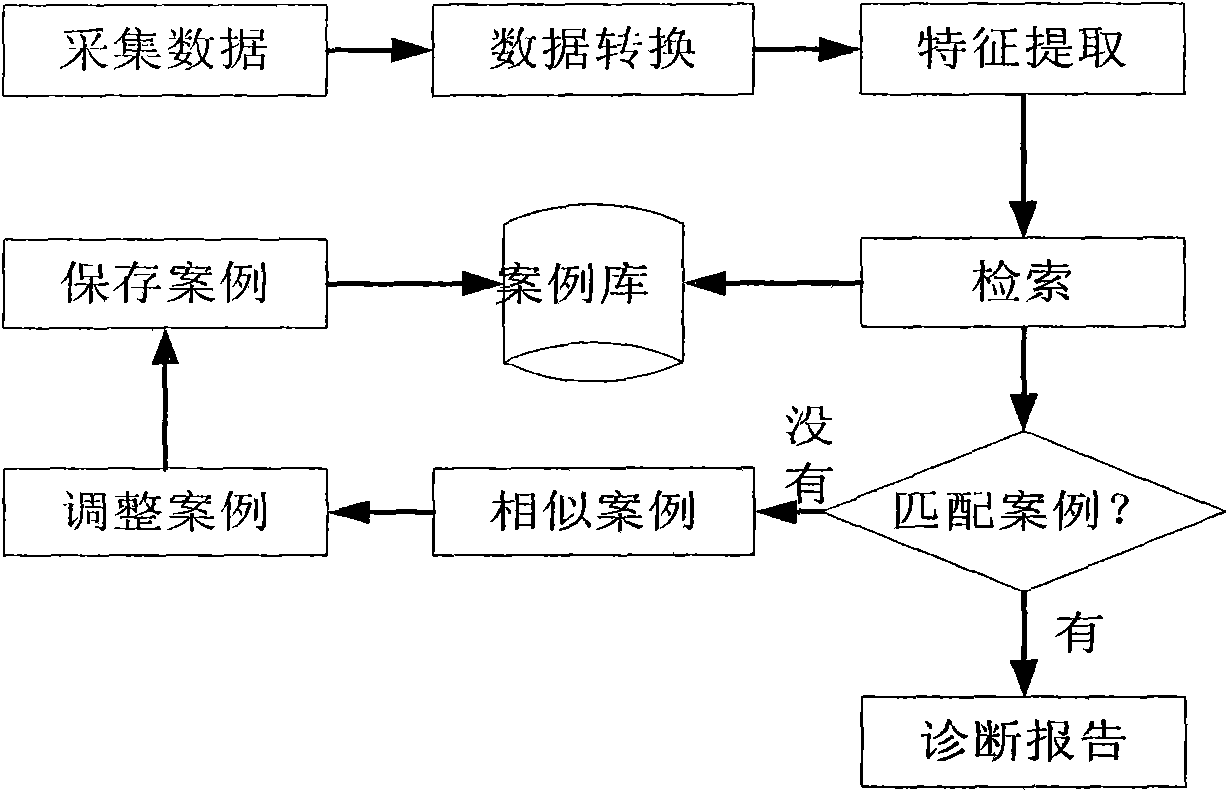

[0043] The specific steps of case reasoning and judgment are as follows: (such as figure 2 shown)

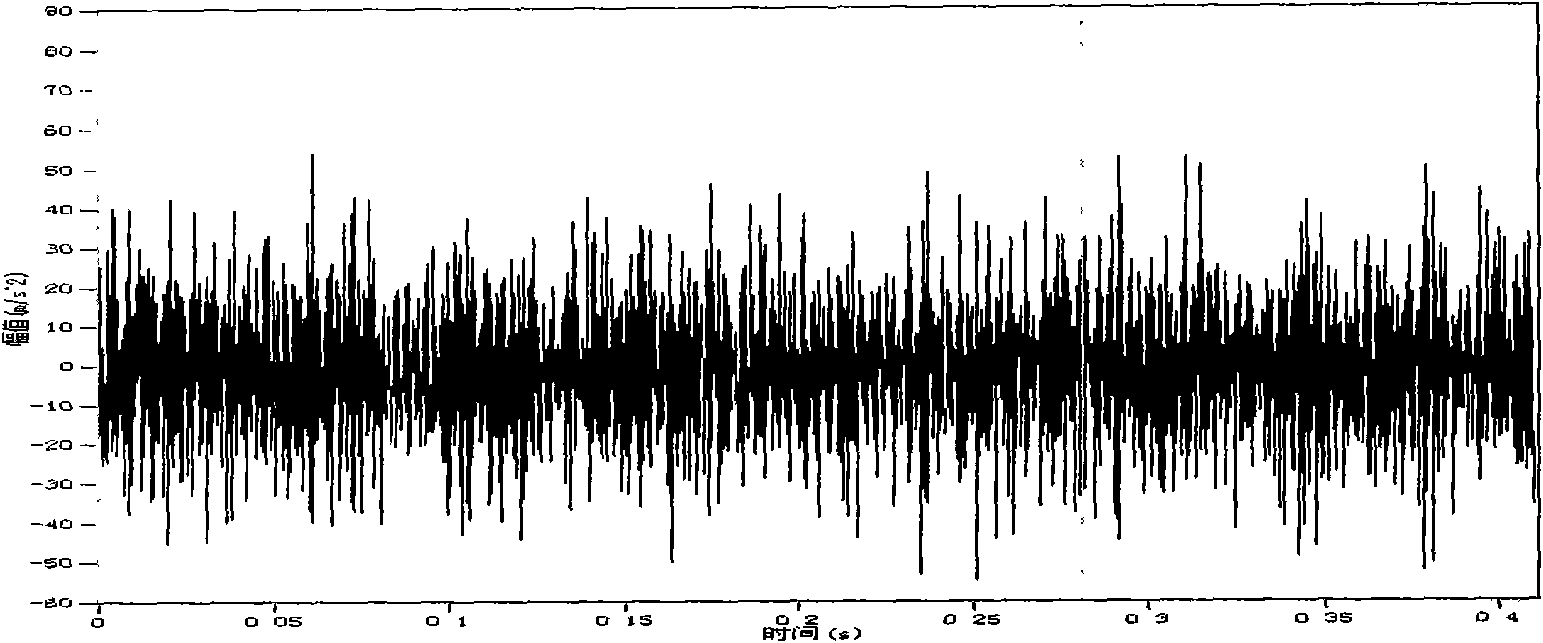

[0044] Through the research on the common typical fault cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com