Device and method for testing temperature fuse assembly

A technology of temperature fuses and test devices, which is applied in the direction of circuit breaker testing, etc., and can solve problems such as fuses, fire refrigerator accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

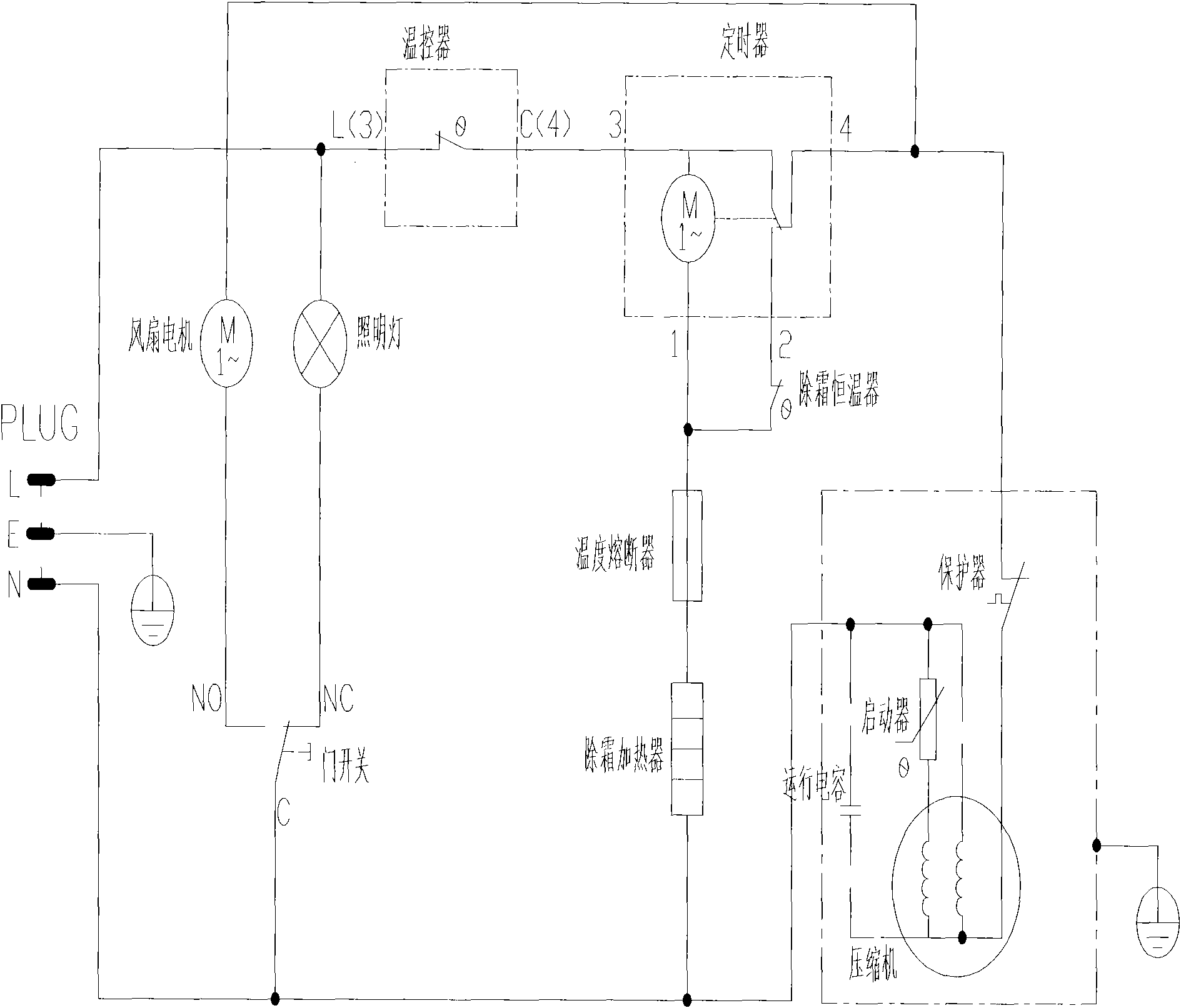

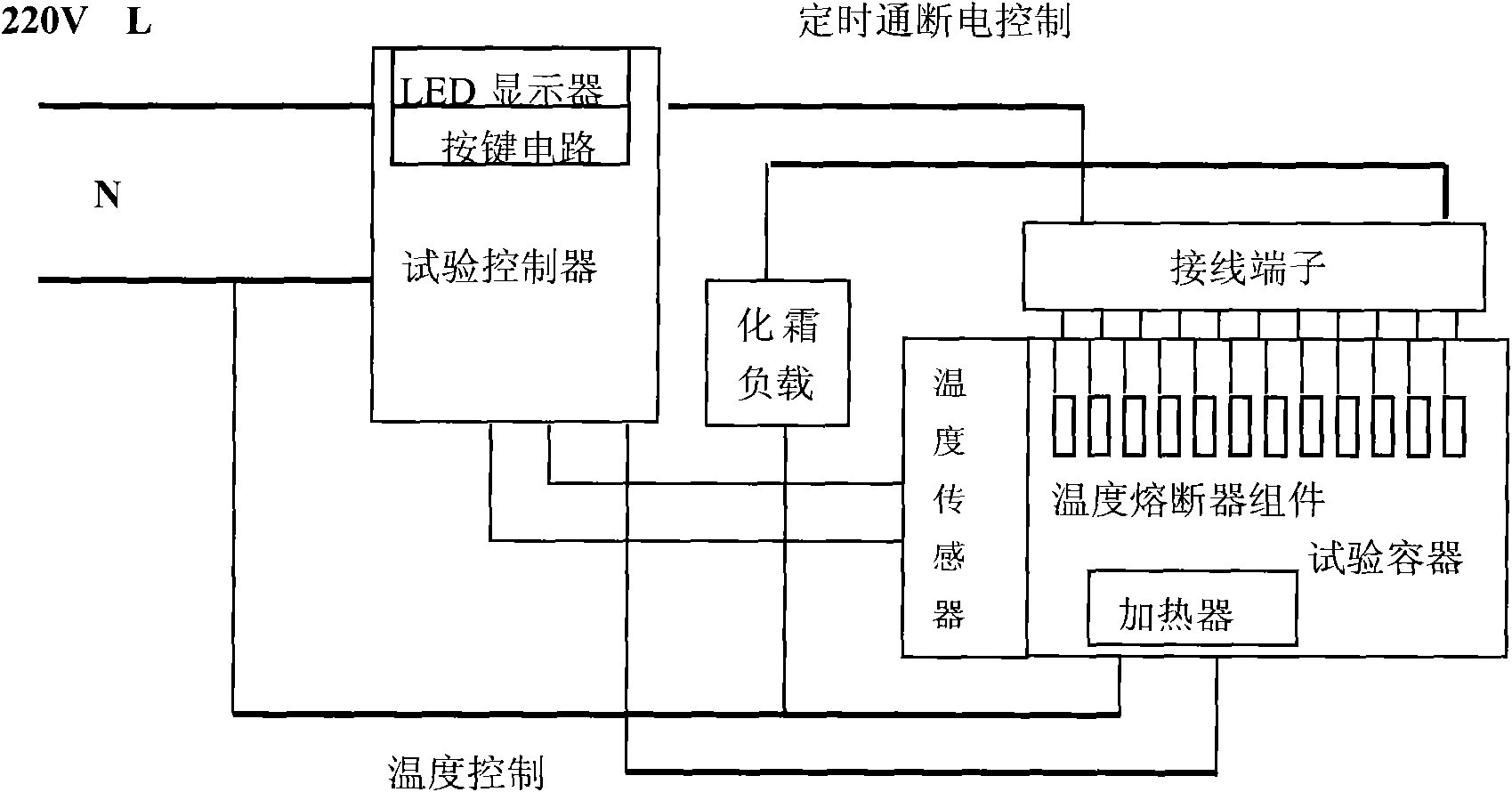

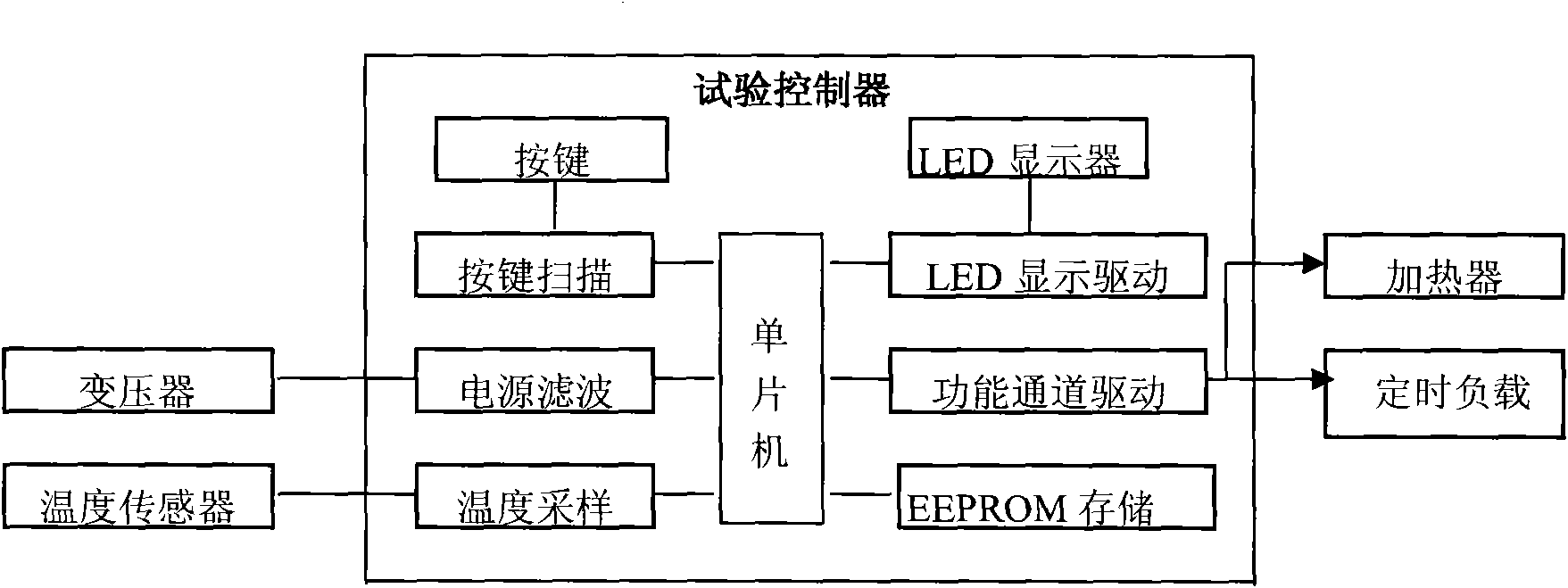

[0028] see figure 2 , The thermal fuse assembly life test device of the present invention. The life test device of the thermal fuse assembly of the present invention carries out the load test according to the test conditions. The test conditions are: put the fuse assembly in water at 45°C, pass a current of 2A for 1 minute, turn off the power for 2 minutes, and cycle 20,000 times. The test conditions are determined by the following methods:

[0029] First determine the test temperature: in practical applications, the temperature fuse assembly is installed on the evaporator of the freezer, the working environment is -35°C to 10°C, and there is often water soaking during defrosting.

[0030] According to the experiment, it is known that the core alloy of the temperature fuse component has super-standard temperature (72 ℃) fusing, super-standard current (10A) fusing, lower than the standard temperature and standard current, long-term under the condition of higher than the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com