Over current protection device

A protection device and overcurrent technology, applied in the direction of electric thermal protection switch, protection switch operation/release mechanism, etc., can solve the problems of difficult working conditions, inseparability, and complex structure of the second bimetallic contact piece, and achieve simple structure and easy operation. Easy assembly and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

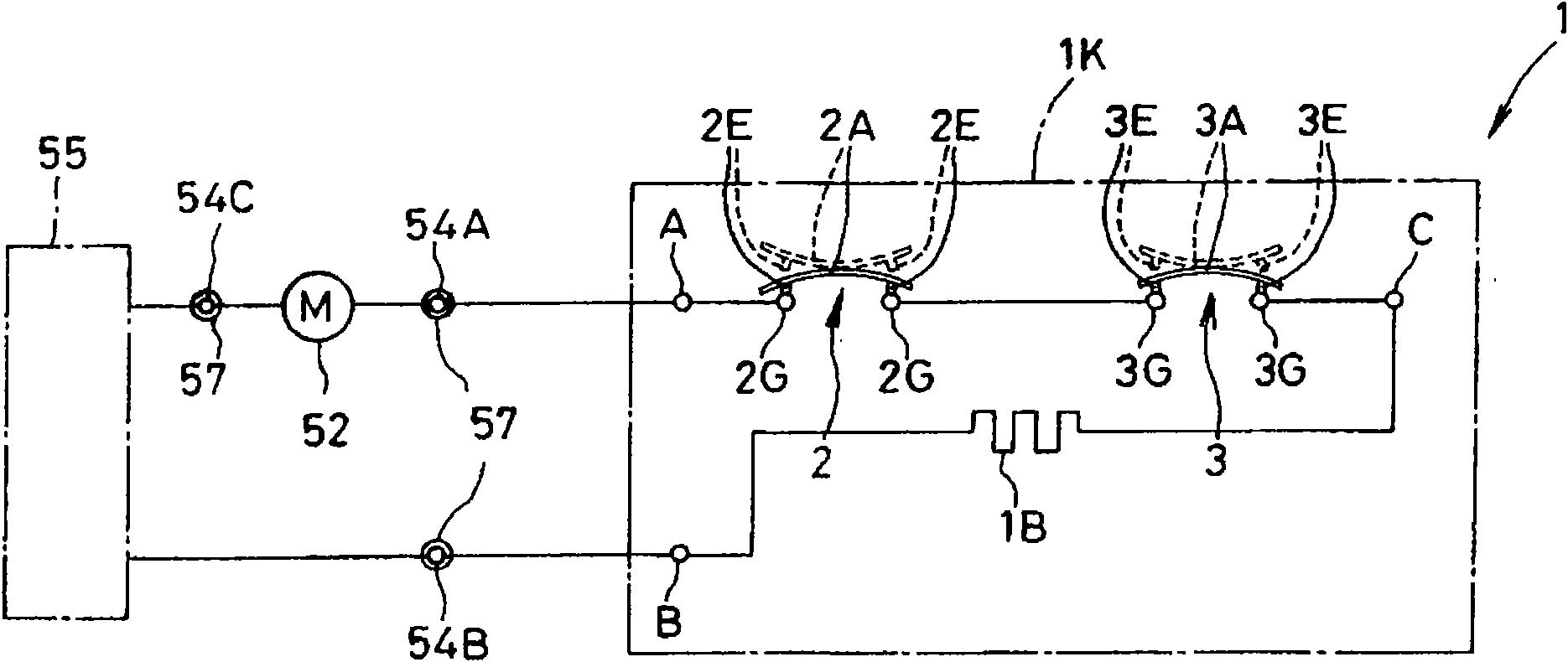

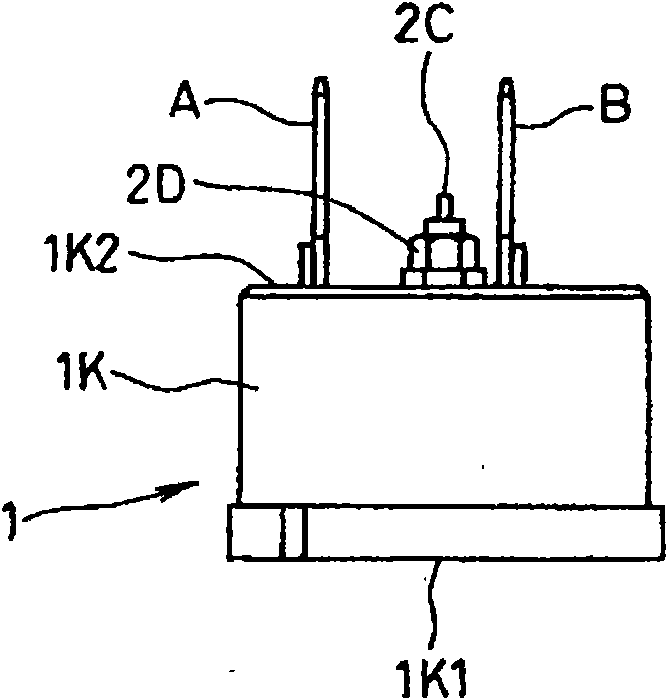

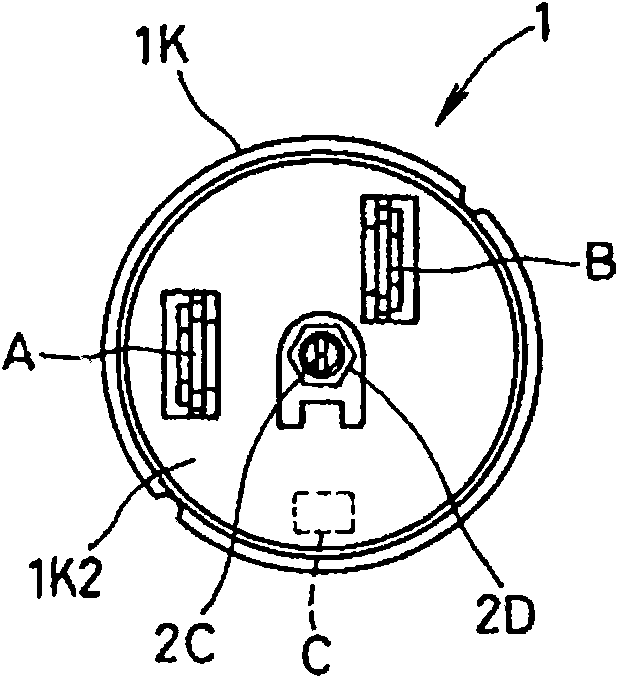

[0051] figure 1 It is a circuit diagram in which the first overcurrent relay unit and the second overcurrent relay unit constituting the overcurrent protection device of the present invention are connected in series; figure 2 It is a side view showing the appearance of the overcurrent protection device of the present invention; image 3 yes means figure 2 A diagram of the external appearance of the terminal part side of the shown overcurrent protection device; Figure 4 From figure 2 The internal composition diagram seen from the opening surface of the overcurrent protection device shown; Figure 5 It is a figure which shows the state which accommodated the overcurrent protection device of the present invention in the cover (cover), and was installed on the upper surface of the closed machine box of the electric compressor; Image 6 It is a specific exploded perspective view of the part where the overcurrent protection device of the present invention is accommodated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com