Group-iii metal nitride and preparation thereof

A nitride and metal technology, which is applied in the field of preparation of Group III metal nitride films and can solve the problems of low epitaxial deposition rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

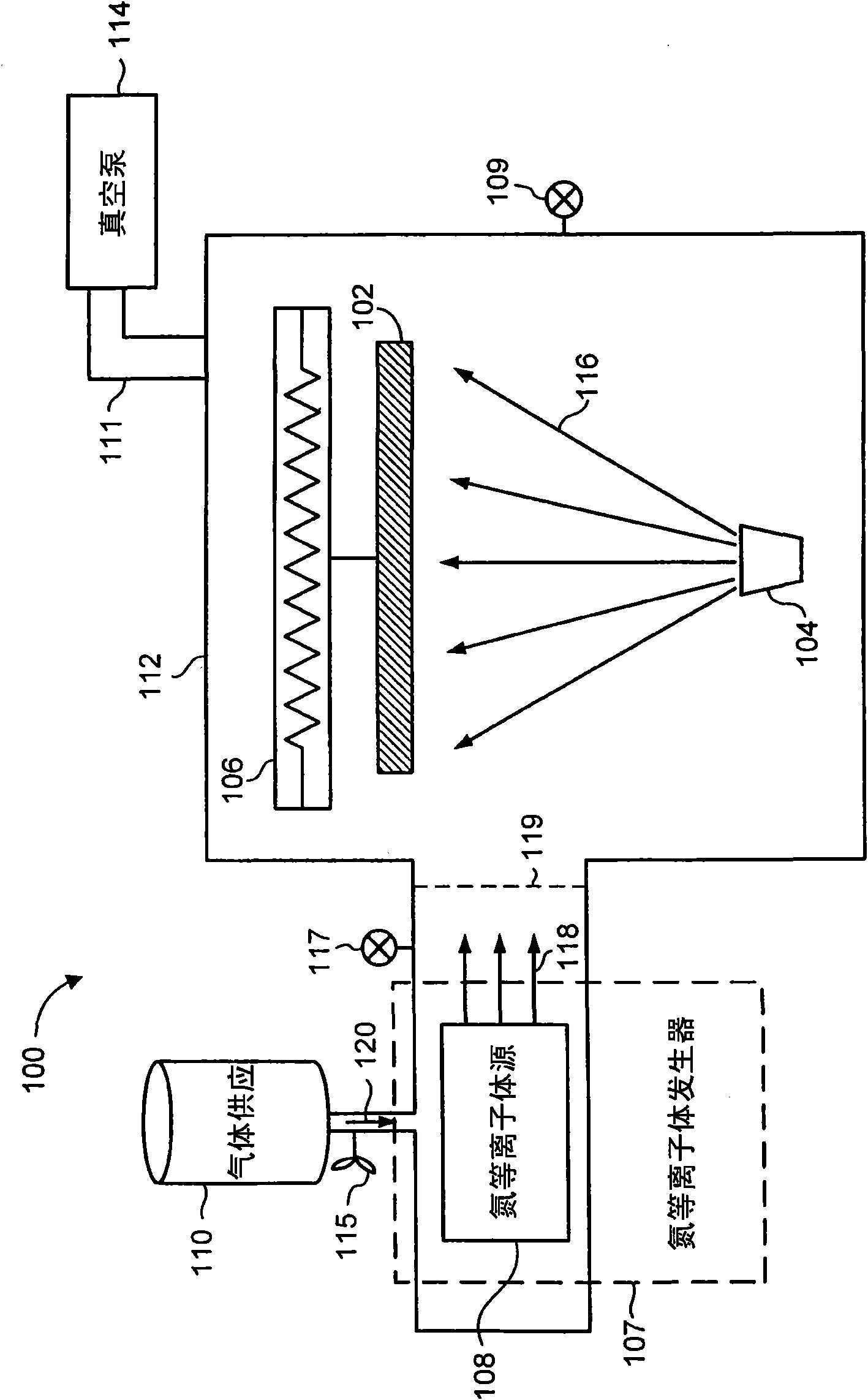

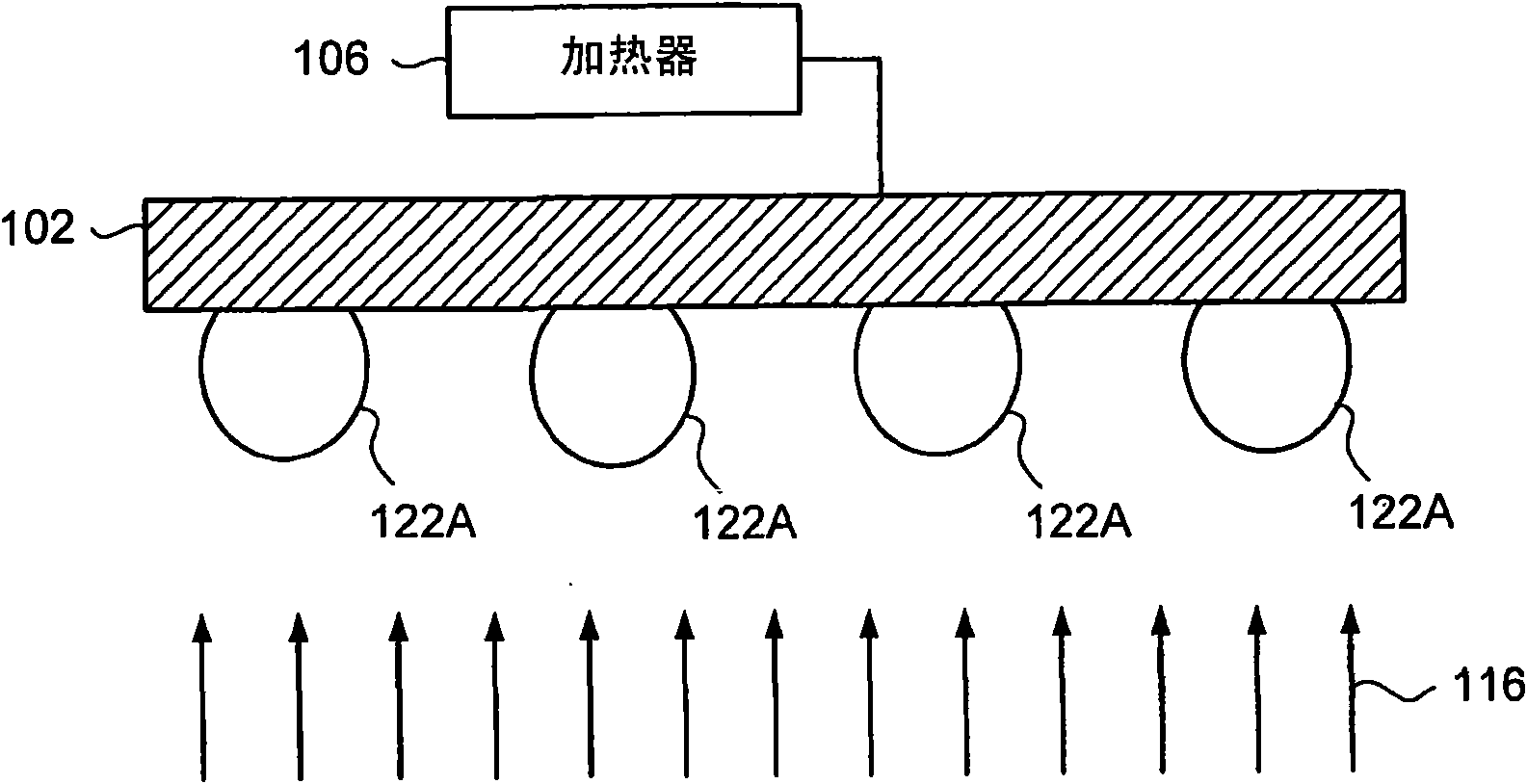

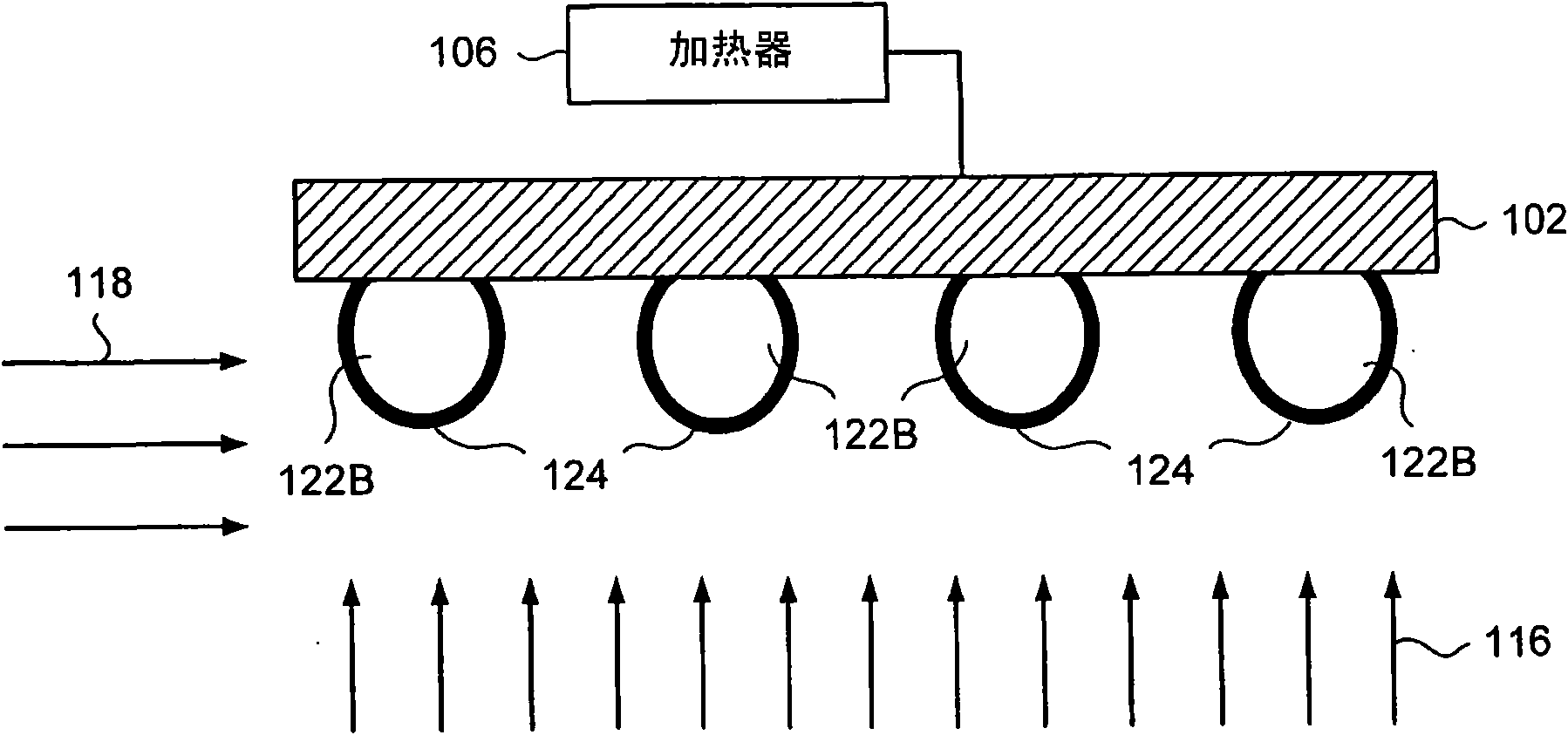

[0029] The technology disclosed in the present invention overcomes the disadvantages of the prior art through the thin film of crystalline or amorphous group III metal nitride and its preparation method. According to the disclosed technique of the present invention, a wetting layer of GaN / Ga solution is formed by exposing Ga droplets grown on a substrate to active nitrogen. The wetting layer is further exposed to reactive nitrogen, which reacts with gallium atoms on the surface of the wetting layer to form GaN molecules. Depending on the thickness of the wetting layer, different types of films (eg, amorphous or crystalline films) can be formed.

[0030] In thinner wetting layers (on the order of up to 50 nm), GaN molecules diffuse into the bulk of the solution, increasing its viscosity. Eventually, all gallium atoms in the reaction are depleted, and the wetting layer transforms into a solid amorphous GaN layer.

[0031] In a thicker wetting layer (in the order of 500 nm-1 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com