Multifunctional rotary tillage ridger

A technology for building a ridge machine and a rotary tiller, which is applied in the fields of tillage machinery, agricultural machinery and machinery, and applications, can solve the problems of artificial soil filling, small ridge shape, and not fundamentally solved, and achieves high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

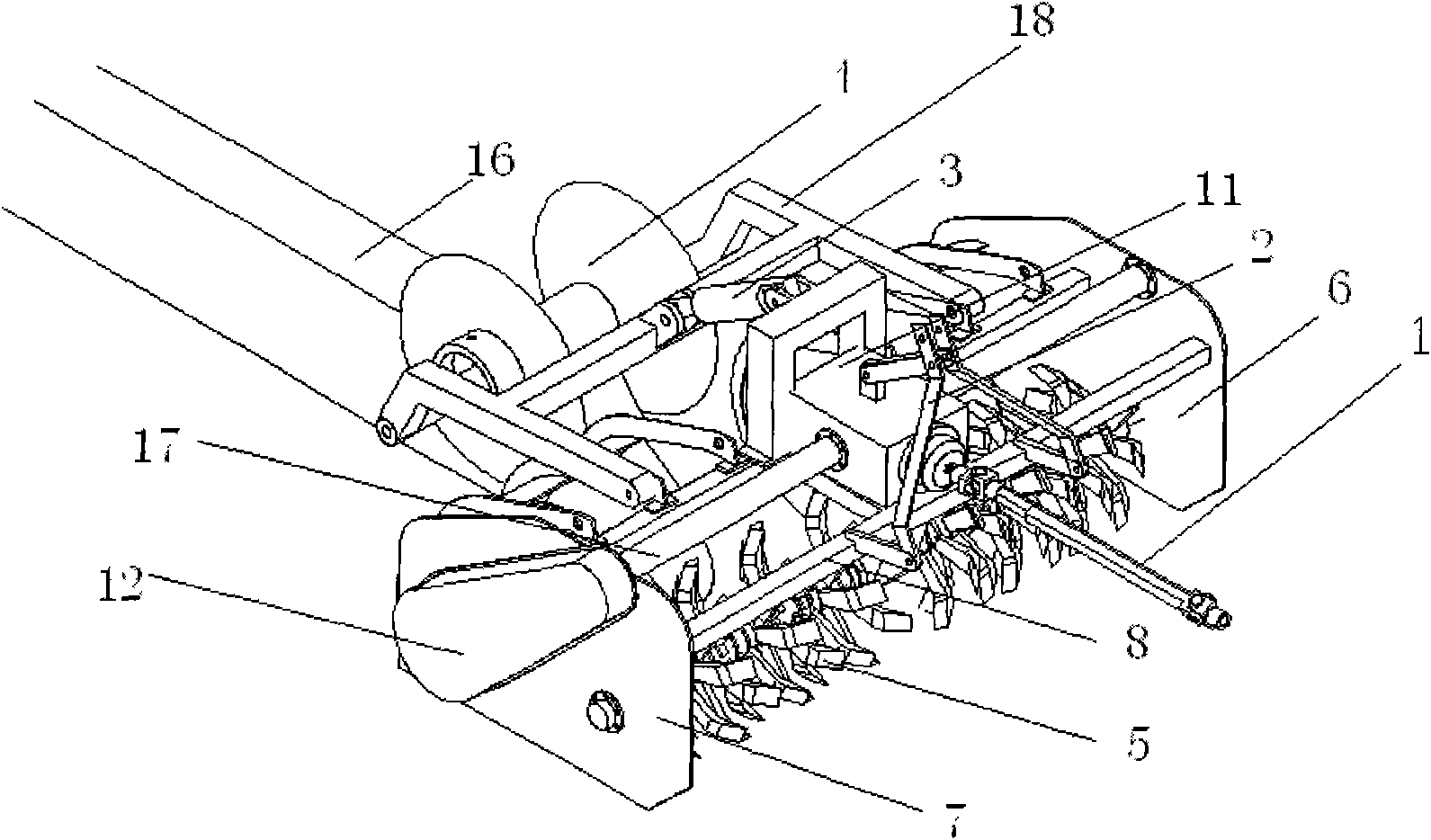

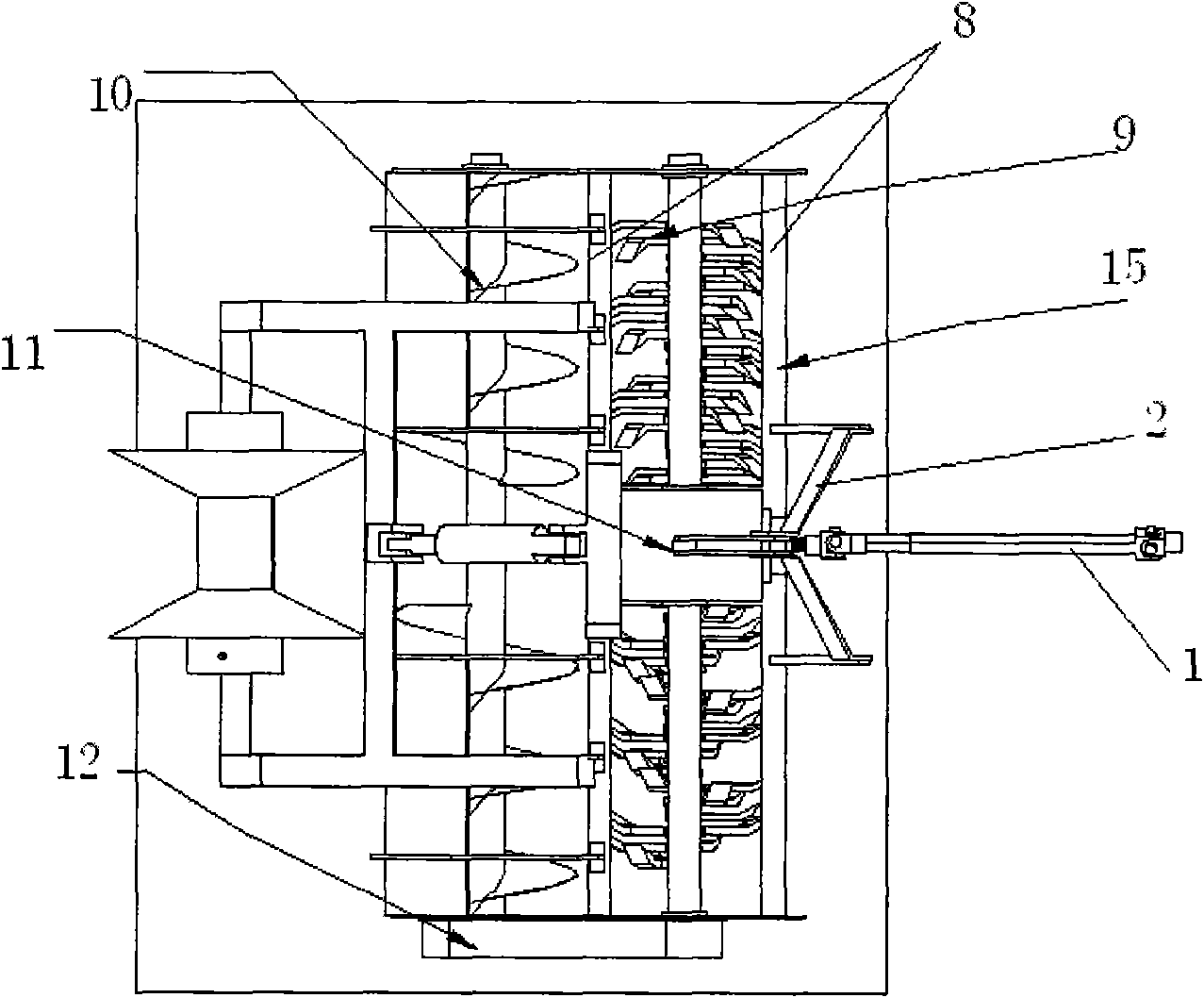

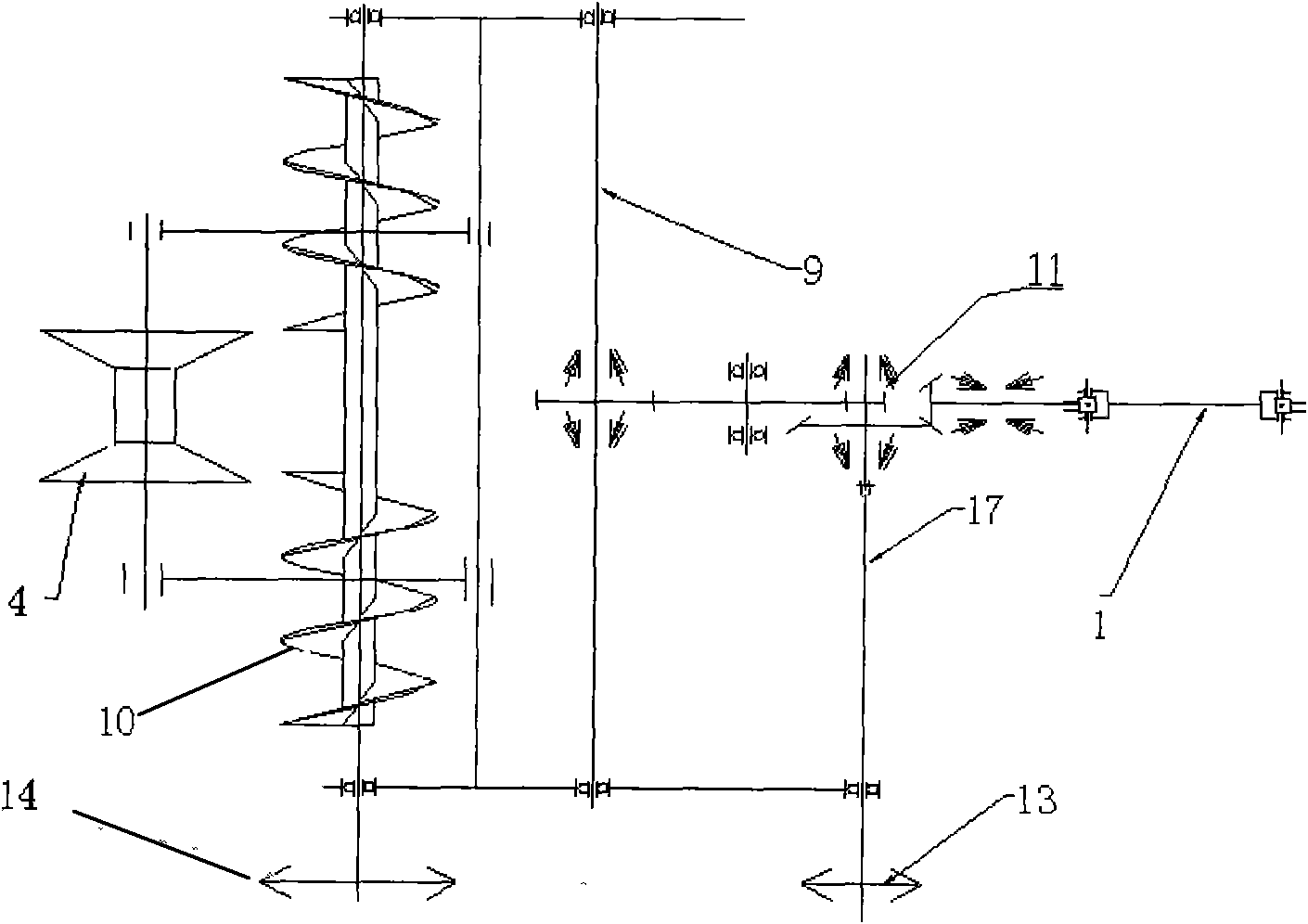

[0035] Below in conjunction with accompanying drawing, the structure of multifunctional rotary tillage ridge building machine of the present invention is described in detail. figure 1 and figure 2 They are the three-dimensional schematic diagram and the top view structural diagram of the overall structure of the rotary tillage ridge building machine respectively. As shown in the figure, the ridge building machine consists of a frame 15, a transfer case 11, a cardan shaft 1, a three-point suspension Cultivator shaft 9, transmission chain assembly 12, spiral soil collector 10, forming wheel 4, compacting oil cylinder 3 and two side connecting plates 6,7 form.

[0036] The frame 15 is composed of two side connecting plates 6, 7 and two connecting beams 8 to form a frame structure, and other assemblies are installed on the frame structure. A three-point suspension frame 2 is installed on the front connecting beam 8 as the traction device of the wheeled tractor, and a transfer ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com