Foamable water-in-oil emulsion

A water-in-oil type and emulsion technology, applied in dairy products, food science, cream substitutes, etc., can solve the problems of general products without proper structure, insufficient effect, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

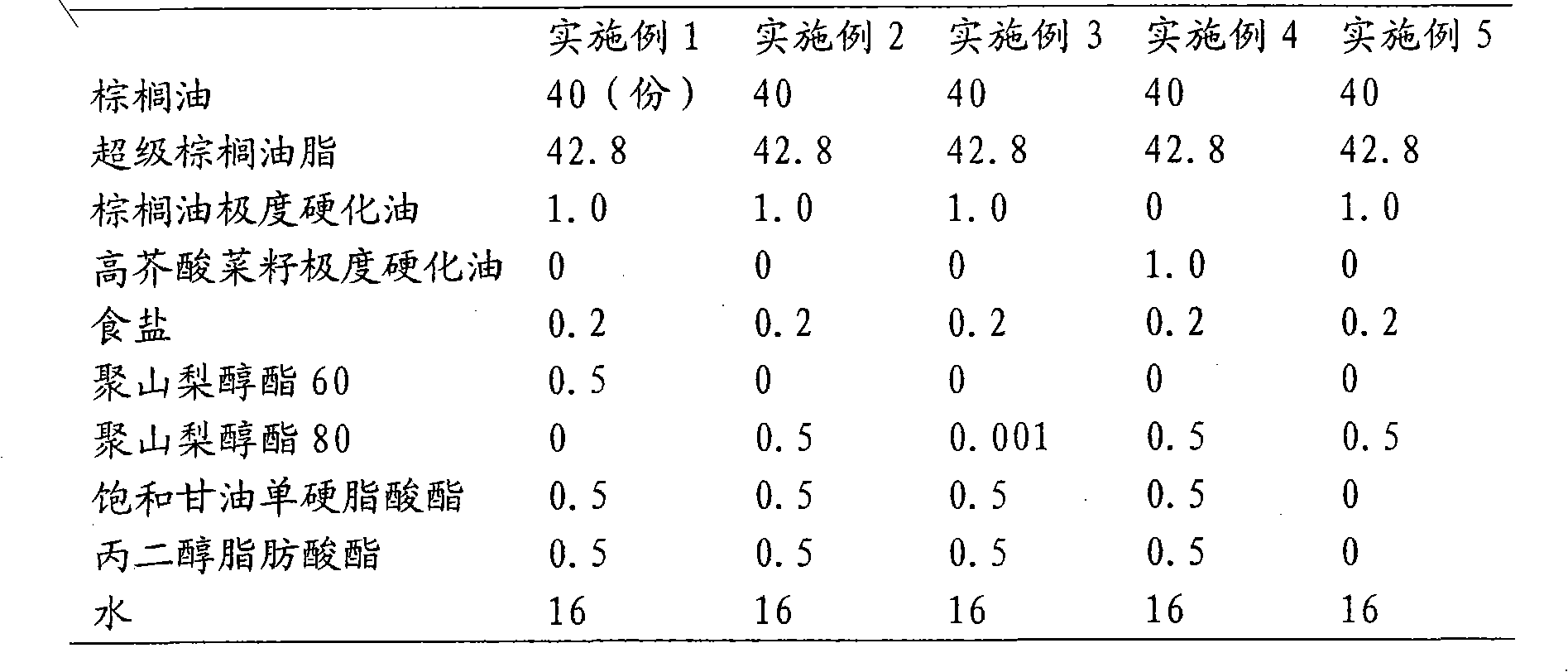

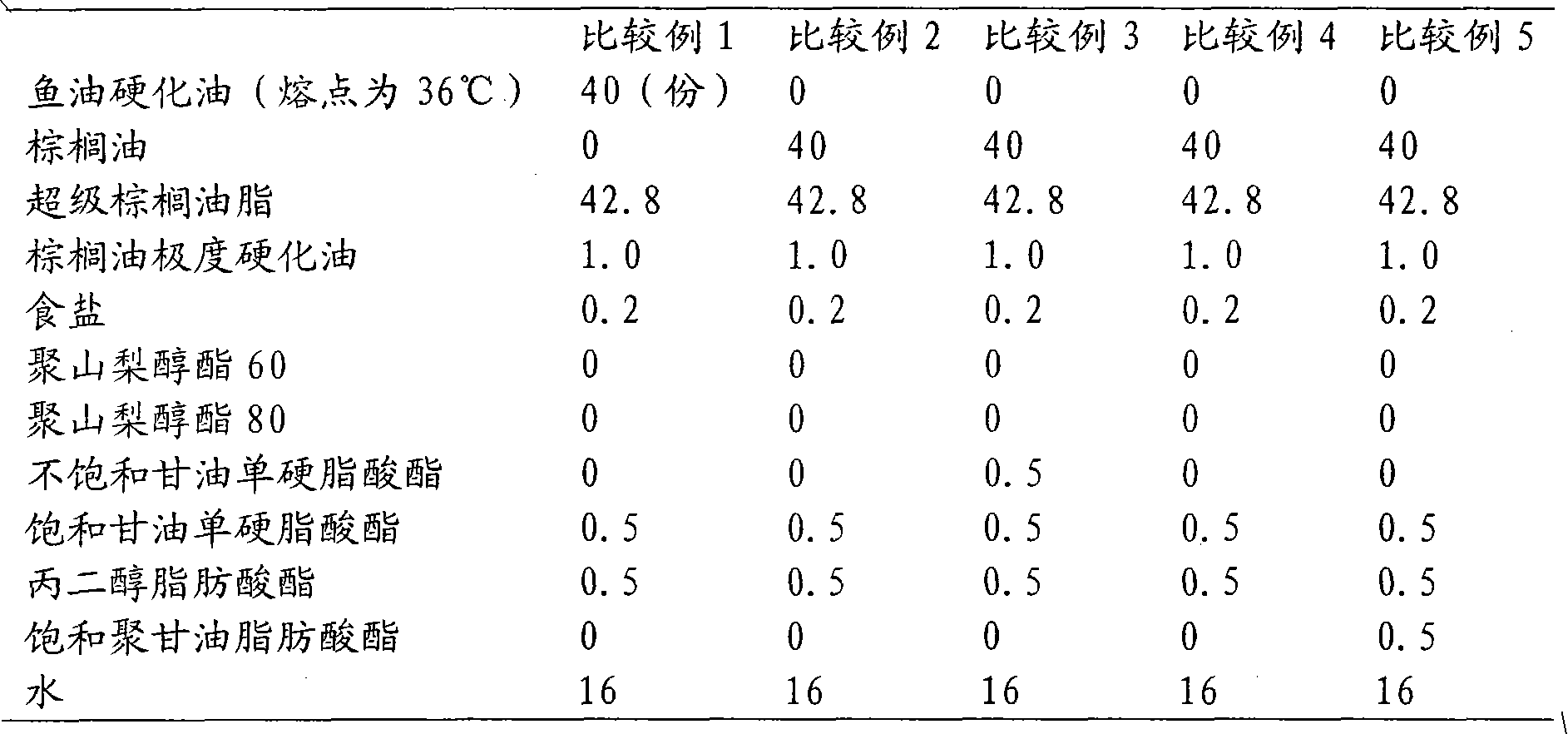

[0040] According to the composition shown in Example 1-Example 4 of Table 1, after adding and mixing all raw materials, it quenched and kneaded with the scraped surface heat exchanger, and obtained the water-in-oil type emulsion. In addition, the SFC of fats and oils is 22% at 10°C and 1% at 35°C. The obtained water-in-oil emulsion was whipped to form cream cream, and the specific gravity of the cream cream when the whipping time was 5 minutes, 10 minutes, 12 minutes, and 15 minutes was measured.

[0041] In addition, 1 kg of water-in-oil type emulsions were whipped using a Kenwood mixer (125 rpm) at room temperature 20 degreeC. The whipping results are shown in Table 3.

[0042] When whipped for 5 minutes, the specific gravity of the cream cream is less than or equal to 0.5, and when whipped for 15 minutes, the specific gravity of the cream cream is less than or equal to 0.35.

Embodiment 2

[0044] The polysorbate 60 of Example 1 was replaced with polysorbate 80, and the water-in-oil type emulsion was obtained on the same conditions as Example 1, and the whipping test was performed.

[0045] Same as Example 1, when whipped for 5 minutes, the specific gravity of the cream cream is less than or equal to 0.5, and when whipped for 15 minutes, the specific gravity of the cream cream is less than or equal to 0.35.

Embodiment 3

[0047] The amount of polysorbate 80 added in Example 2 was changed from 0.5% to 0.001%, and a water-in-oil emulsion was obtained under the same conditions as in Example 1, and a whipping test was performed.

[0048] Compared with Example 1, when whipped for 5 minutes, the specific gravity of cream cream was slightly higher than 0.55, and when whipped for 15 minutes, the specific gravity of cream cream reached 0.39.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com