Blade carrier replacing device of combined flying shear

A technology of combined flying shears and flying shears, which is applied to the attachment of shearing machines, devices for shearing forming blanks, shearing devices, etc., which can solve the problems of long time and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

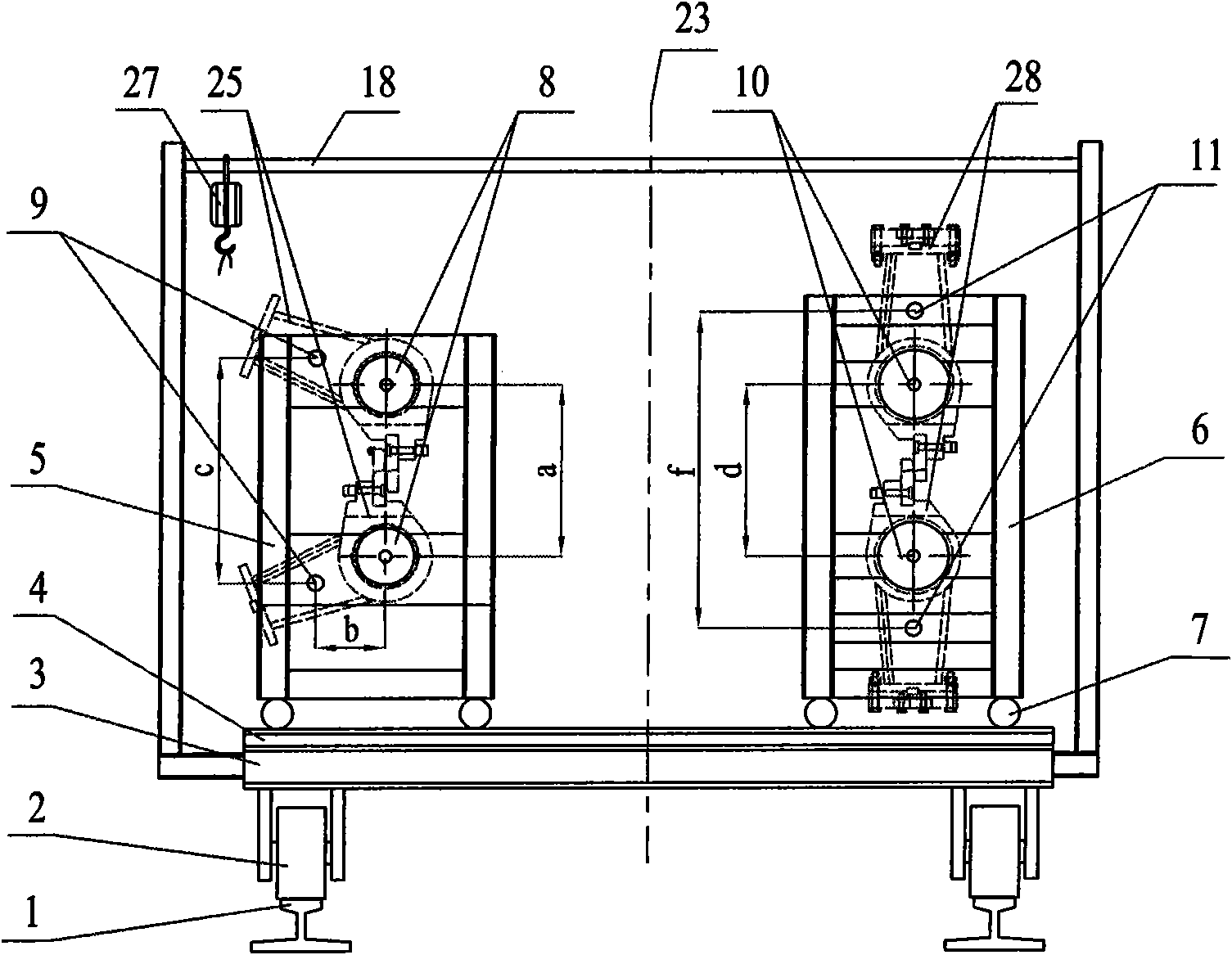

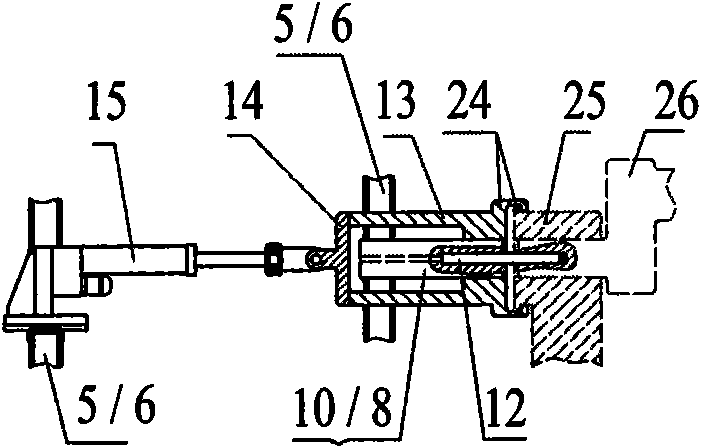

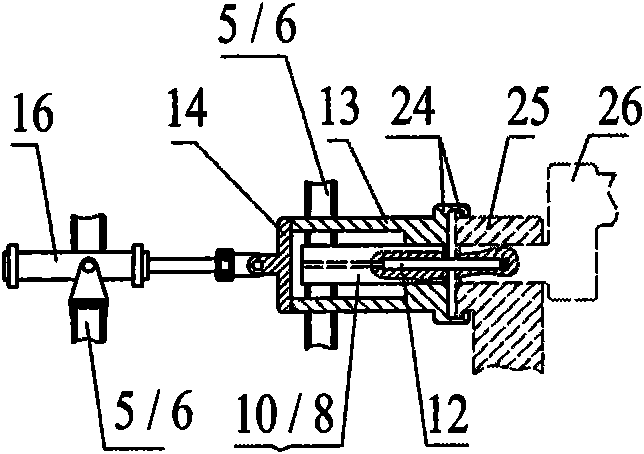

[0019] see figure 1 , the tool holder replacement device of the combined flying shear machine of the present invention includes a cart 3 walking on the ground track 1, a trolley walking track 4 is arranged on the chassis of the cart, and a useful track 4 is arranged on the trolley walking track 4 The trolley A 5 used for loading and unloading and adjusting the crank tool rest and the trolley B 6 for loading and unloading and adjusting the rotary tool rest.

[0020] Described trolley 3 comprises vehicle frame chassis, and the cart wheel 2 that is connected with chassis, is provided with trolley walking track 4 on chassis, and described trolley walking track 4 has the intermediate tool that aligns with the cutting center line of flying shears. Bit 23. At ordinary times, dolly first 5, dolly second 6 are positioned at the both sides of middle station 23 respectively, and when cart 3 was on the ground rail 1, this middle station 23 is aimed at the cutting center line of flying sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com