V-shaped block and manufacturing method thereof

A manufacturing method and cemented carbide technology are applied in the field of V-shaped block, the manufacture of the V-shaped block, and the field of process equipment, which can solve problems such as affecting production efficiency and adversely affecting the quality of cylindrical workpieces, so as to improve production efficiency and reduce the number of repairs. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

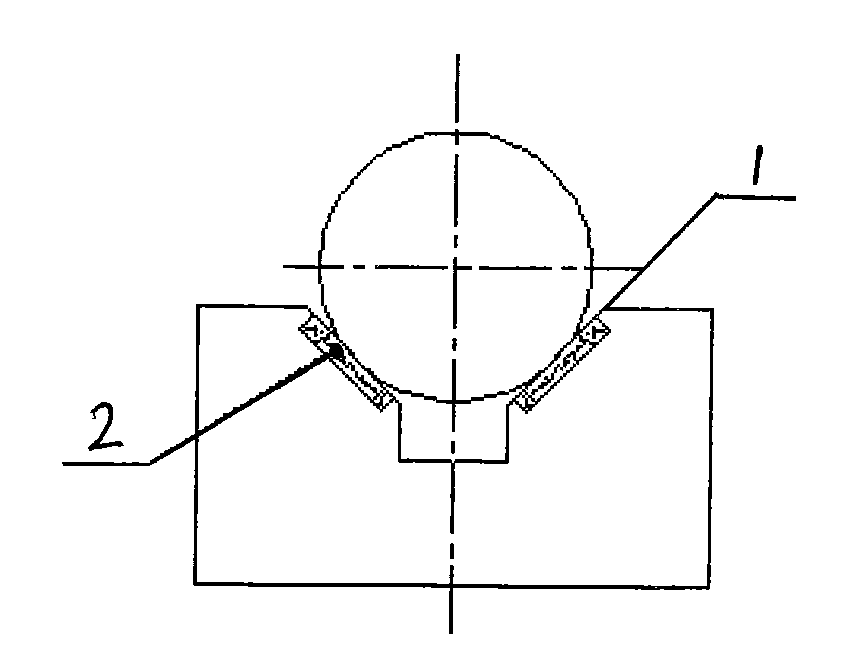

[0015] like figure 1 As shown, a V-shaped block has a V-shaped surface 1 on the V-shaped block, and a groove is opened on the V-shaped surface, and cemented carbide 2 matching the size of the groove is welded in the groove.

[0016] The manufacture method of above-mentioned V-shaped block:

[0017] First, make a groove on the V-shaped surface of the V-shaped block;

[0018] Then, put cemented carbide that matches the size of the groove into the opened groove and weld it;

[0019] Finally, grind the V-shaped surface welded with cemented carbide.

[0020] Working principle of the present invention:

[0021] During the operation of the present invention, the cylindrical workpiece is placed between the V-shaped surfaces 1 of the V-shaped block on which the cemented carbide 2 is fixed to perform clamping, positioning, inspection or correction, and marking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com