Automatic correction device of heavy-duty conveyor belt

An automatic deviation correction device and conveyor belt technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of complicated structure of deviation correction device, difficult maintenance, failure of deviation correction mechanism, etc., and achieve sensitive mechanical action and use The effect of long life and high guiding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

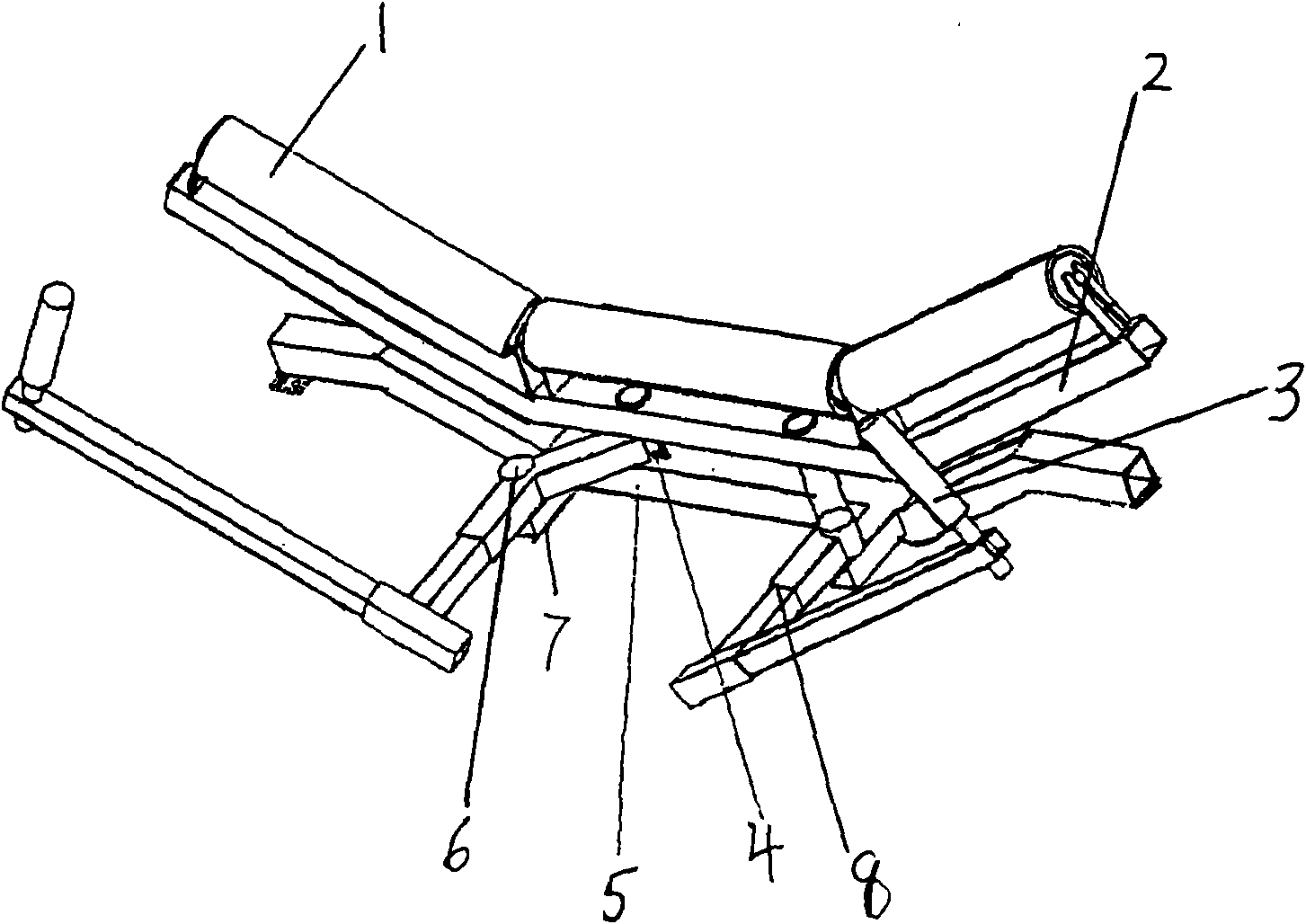

[0013] An automatic deviation correction device for a heavy-duty conveyor belt, comprising a crossbeam 5, an idler bracket 2, an idler 1 is installed on the bracket bracket 2, and a supporting wheel is fixedly installed on the left and right sides of the lower end of the idler bracket 2 4. The support wheels 4 are mounted on the beam 5; the connecting rod 7 is fixedly connected to one side of the beam 5; the same side of the two support wheels 4 is respectively rotatably equipped with a crank arm 8, The middle part of the crank arm 8 is rotationally connected with the connecting rod 7 through the linear bearing 6 , and the vertical roller 3 is installed on the outer end of the crank arm 8 .

[0014] When the belt "runs off" to one side, the vertical roller on that side is stressed and moves accordingly, driving the support seat to move as a whole. At this time, the idler roller on the support seat also moves accordingly. The moving direction of the roller and the moving direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com