Trickle type pure oxygen dissolving device

A pure oxygen and dissolved oxygen technology, applied in the field of oxygen dissolvers, can solve the problems of high manufacturing, installation, maintenance and price, high energy consumption of water circulation, and low oxygen utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

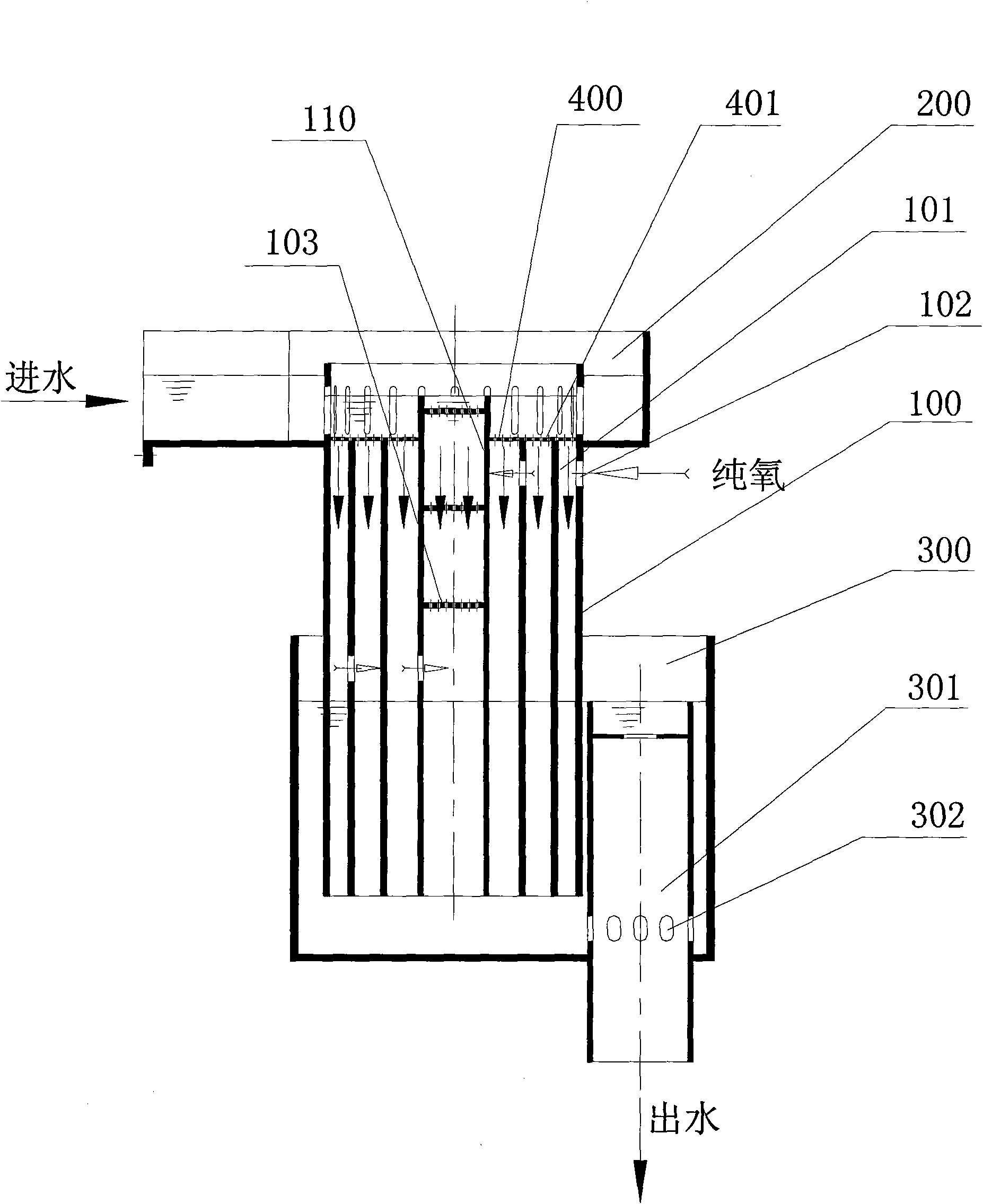

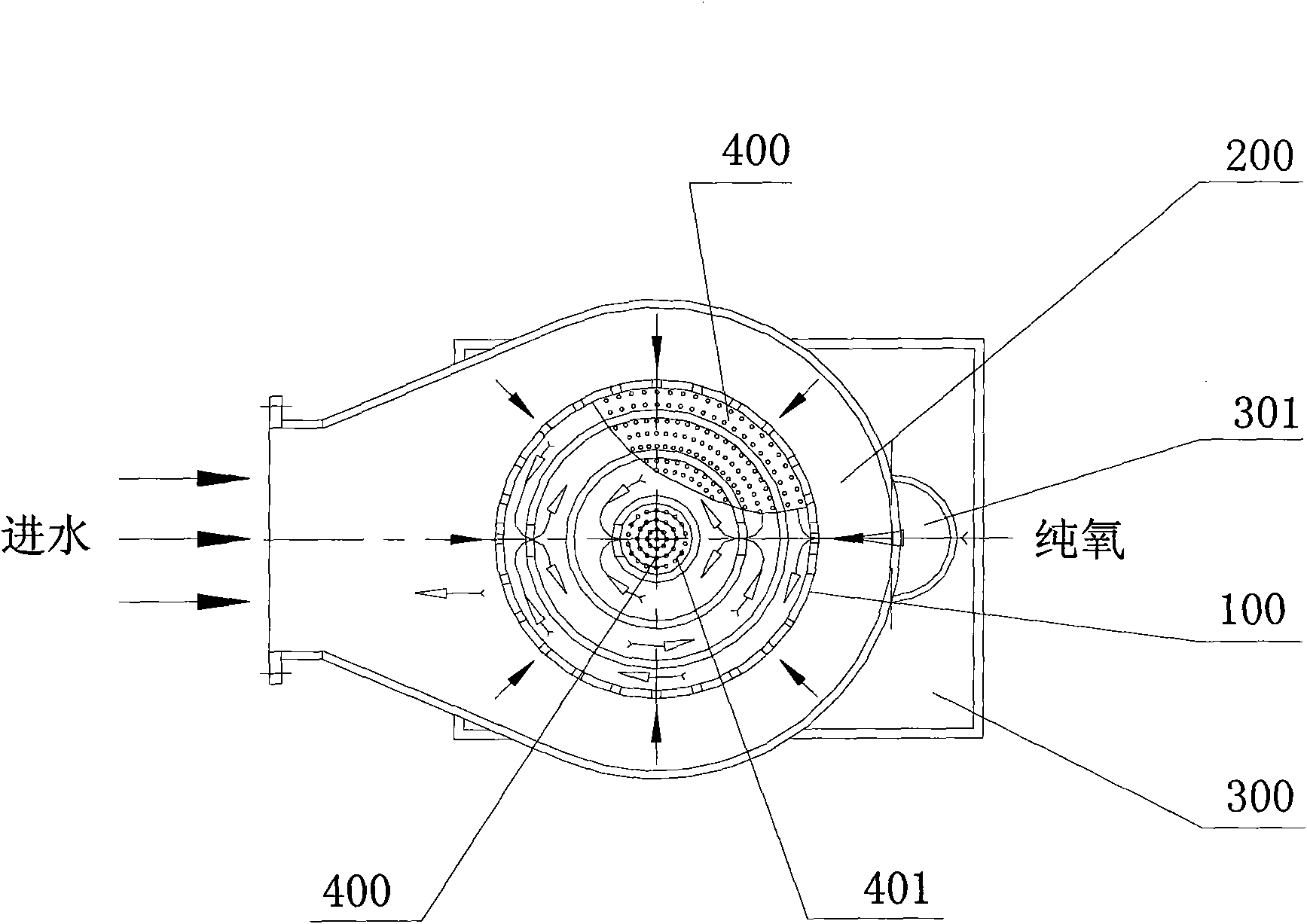

[0023] Such as figure 1 , figure 2 As shown, the trickle-type pure oxygen dissolved oxygen device of the present invention includes a group of mixing chambers 100, a water distribution tank 200 and a water outlet tank 300; the water distribution tank 200 is arranged above the mixing chamber 100, and the water outlet tank 300 is arranged on the mixing chamber Below the chamber 100 , a drain pipe 301 with a water level maintaining function is provided in the outlet tank 300 . In this embodiment, the mixing chamber 100 is a group of annular chambers.

[0024] The mixing chamber 100 is composed of several cavities 101 whose diameter gradually decreases from the outside to the inside. Generally, the number of cavities 101 is 3 to 5, and the air inlet pipe 102 is arranged between the cavities 101 from the outside to the inside. Connected to each other, oxygen enters the mixing chamber 100 through the intake pipe 102, so that pure oxygen gradually enters the inner chamber 101 from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com