Petrol engine air inlet passage with high-tumble intensity and high-flow coefficient

A gasoline engine, flow coefficient technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problem of tumble flow intensity and flow coefficient cannot be taken into account, and achieve the effect of high tumble flow intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

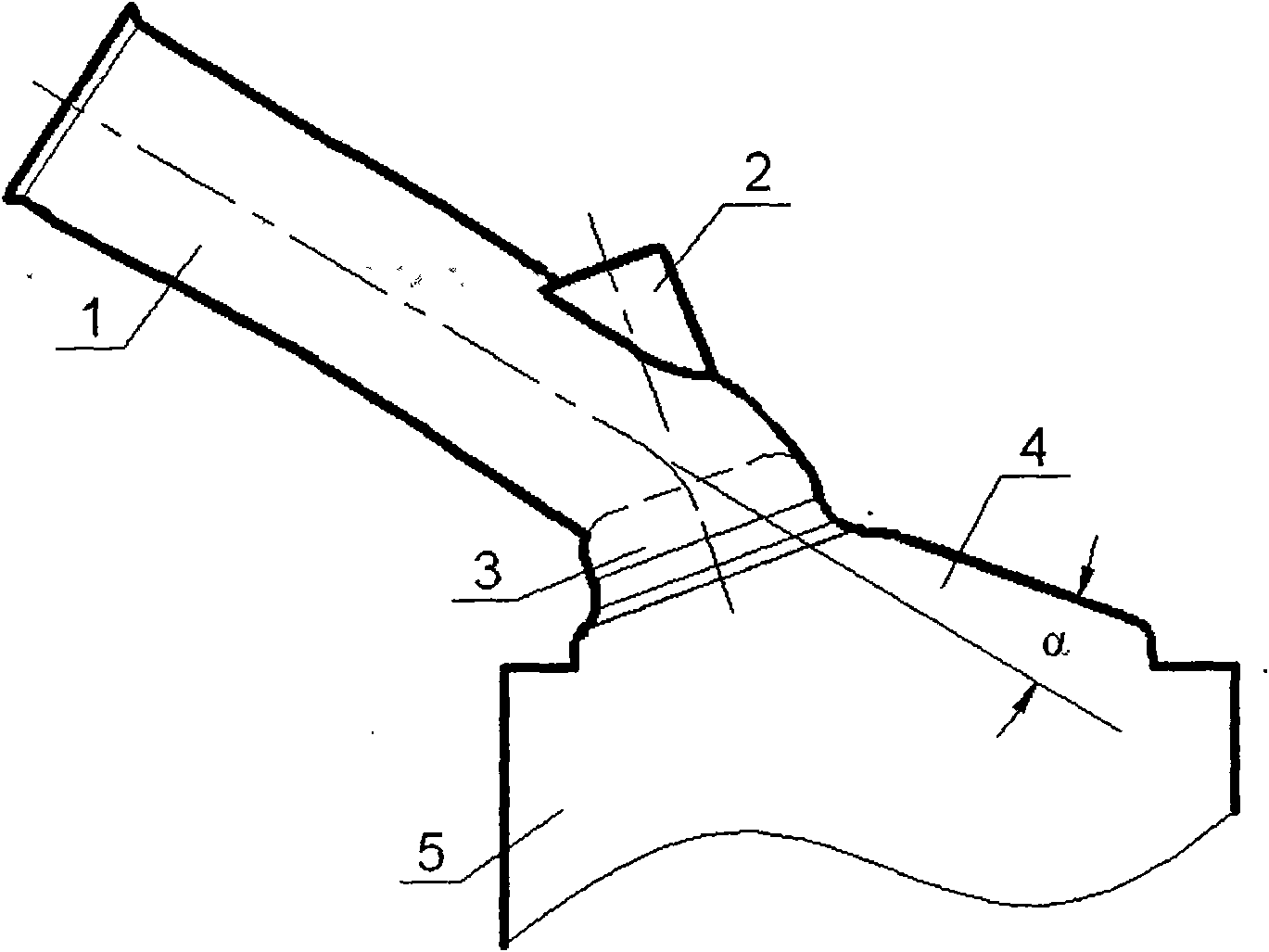

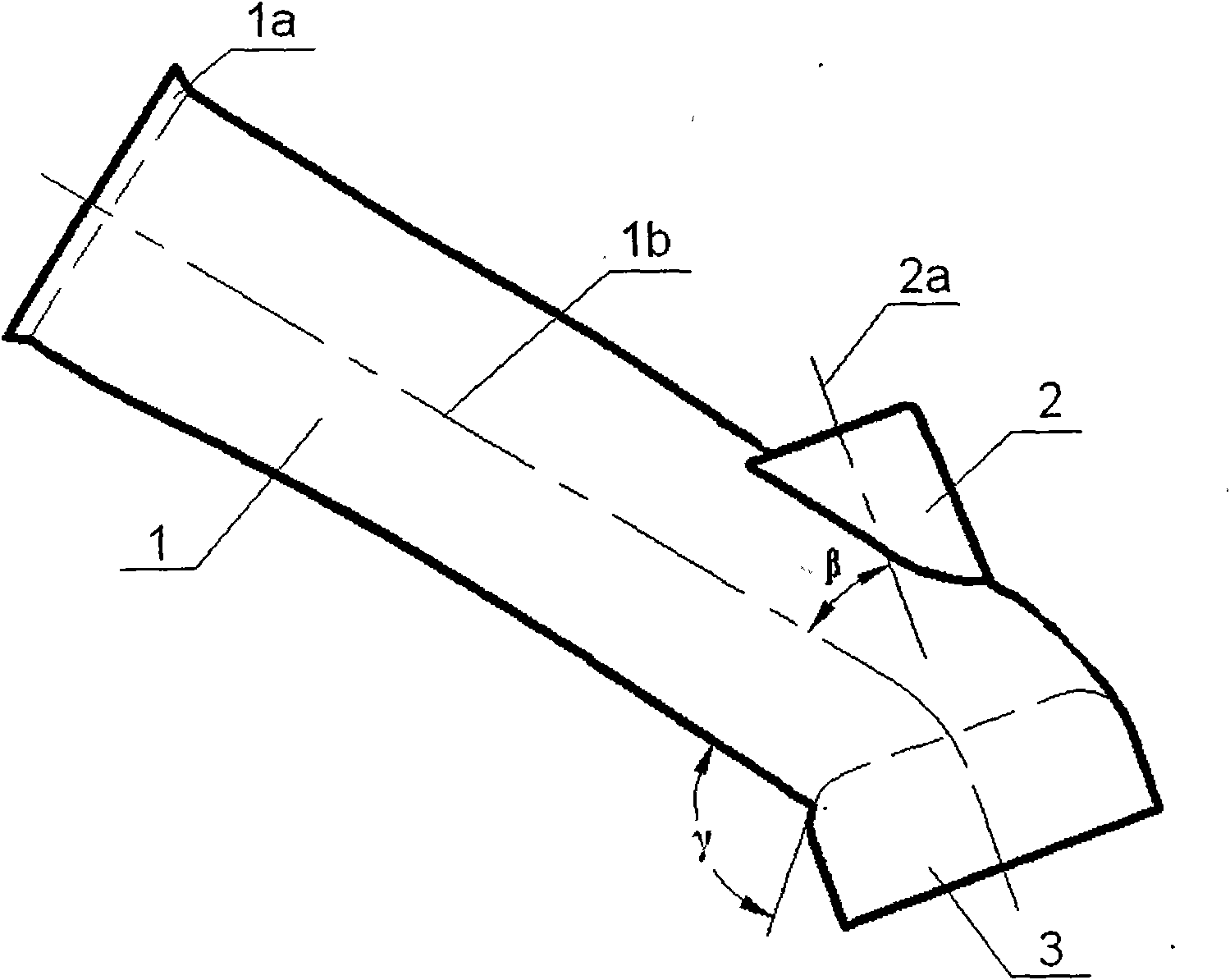

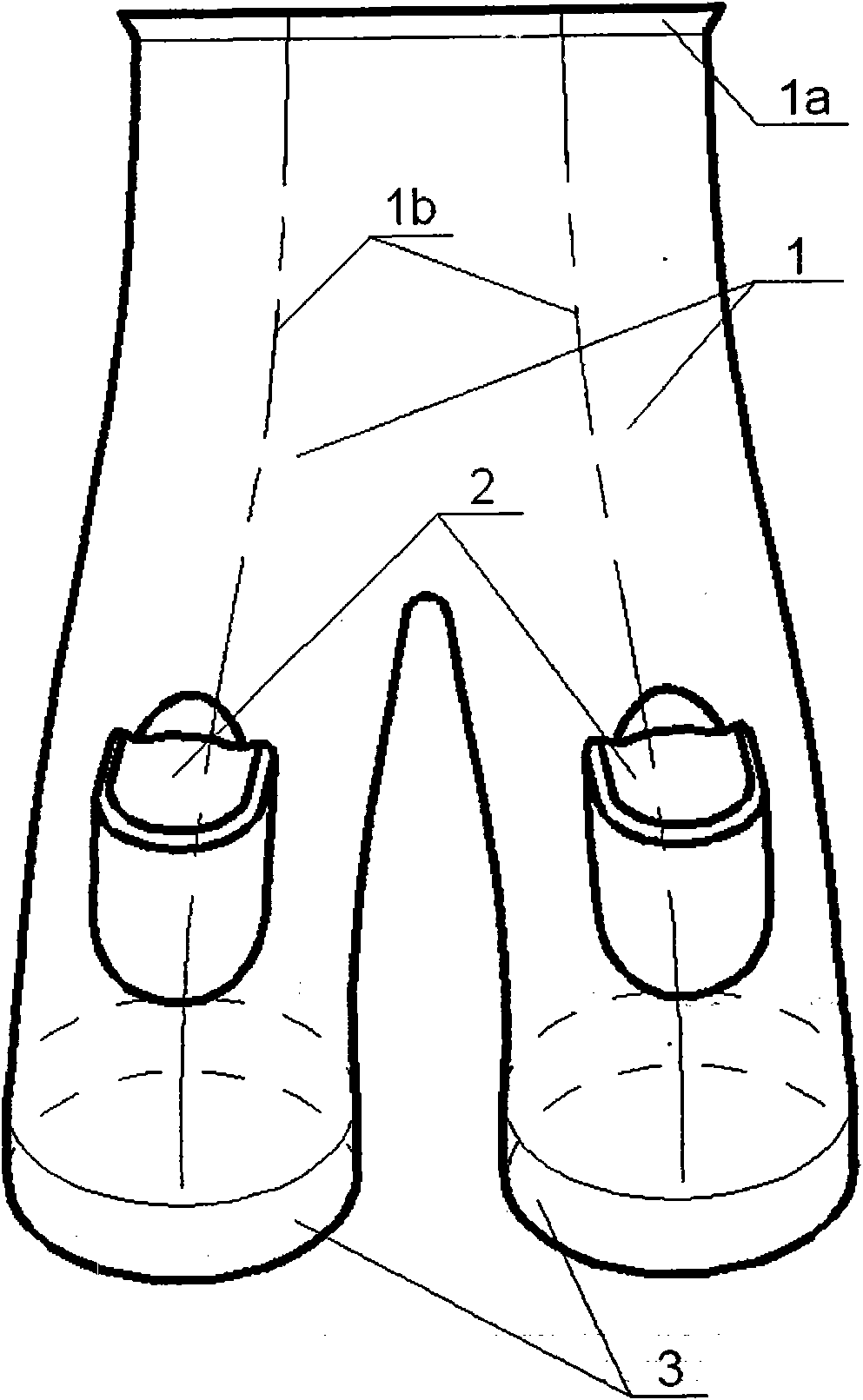

[0023] exist figure 1 and 2 In the structure shown, the intake port is an integral two-intake valve high-position tangential intake port, which has an intake port body 1, a valve guide boss 2 and an airway throat part 3, and the combustion chamber matched with it Chamber 4 is a sloping roof combustion chamber. The inlet 1a of the air inlet has a chamfer of 1×30°, which is formed by casting; the boss 2 of the valve guide is outside the main body 1 of the air inlet. The airway throat-to-throat ratio is 3. This part is formed by machining, and the angle γ between the two curved surfaces adjacent to the airway throat body 1 and the airway throat 2 in the tangential direction is 100°. The centerline 1b of the air inlet is basically a straight line when viewed from the side projection of the air inlet body (that is, the projection on the side view), and the straightness is less than 1mm. The cross-sectional shape of the air inlet body 1 is elliptical. Line 1b changes gently, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com