Integral planet carrier of large-scale single-walled cantilever

A planet carrier, integral technology, applied in the field of planet carrier, can solve the problems of rigidity, bearing capacity, balance performance and self-aligning effect defects, and achieve the effect of compact structure, good balance performance and good self-aligning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

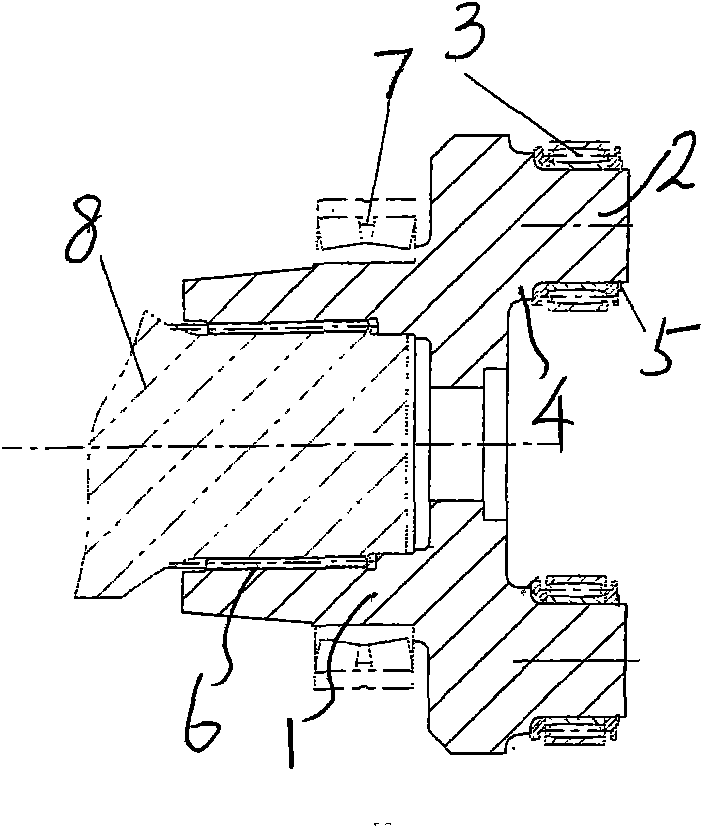

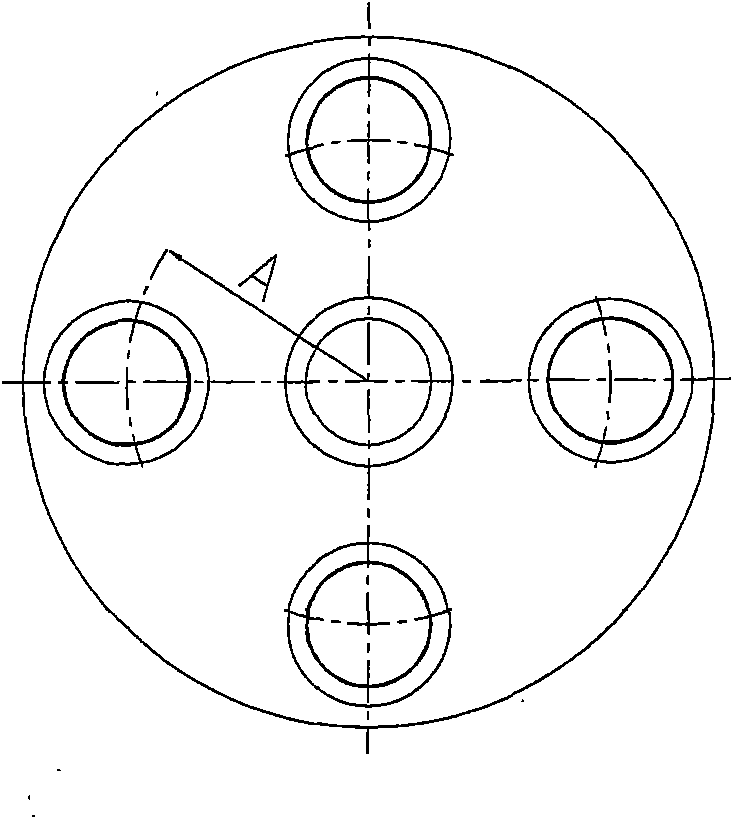

[0012] A large single-wall cantilever integral planetary carrier, which is in the form of integral forging, has a planetary carrier body 1, and one end of the planetary carrier body is provided with 3 to 4 cantilevers 2 (that is, planetary shafts) for installing planetary gears along the circumference, and each cantilever A single self-aligning bearing 3 that realizes single-point floating support is installed on the top. The self-aligning bearing is positioned axially through the cantilever shaft shoulder 4 and the shaft circlip 5. The other end of the planet carrier body is connected to the next-stage transmission mechanism 8. Inner spline 6 structure, a single self-aligning bearing 7 that realizes single-point floating support is set on the planet carrier body.

[0013] The radial distance A between the center of the cantilever and the center of the planet carrier is 400-800mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com