A method and device for detecting the inner diameter of a generator magnetic pole coil

A magnetic pole coil and size detection technology, applied in the direction of mechanical diameter measurement, can solve the problems of high labor intensity of the operator, increase the production cost of the unit, and be unfavorable for environmental protection, and achieve the effects of simple operation, increased speed, and wood saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

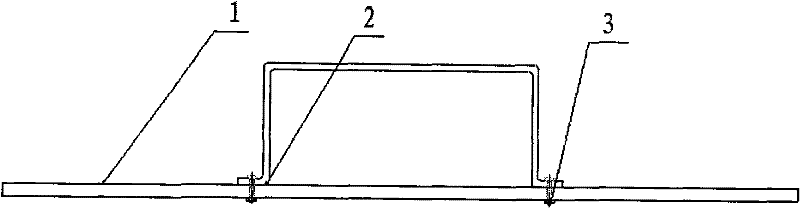

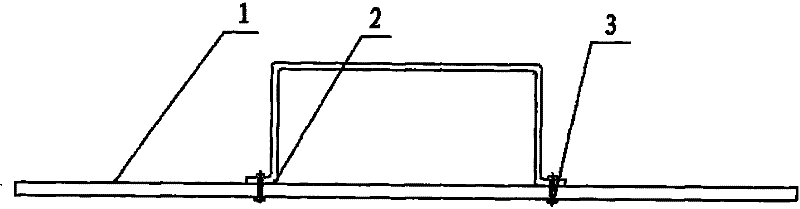

[0022] A method for detecting the inner diameter of the magnetic pole coil of a generator is that the magnetic pole coil is subjected to flat winding of copper bars, coil annealing, cold pressing, lead wire simmering and bending, pad inter-turn insulation for inter-turn hot pressing, and then performs sanding treatment on the outside of the magnetic pole coil. The inner diameter size of the magnetic pole coil is detected by using the detection verification model to simulate the magnetic pole core, so that the verification model can pass through the magnetic pole coil smoothly, and the purpose of detecting the inner diameter size of the magnetic pole coil is realized. When using the detection calibration model to simulate the magnetic pole core to detect the inner diameter of the magnetic pole coil, consider padding the inter-turn insulation by 1-3mm. In order to ensure the overall quality of the inner insulation and save the insulation material of the body.

[0023] Use the ma...

Embodiment 2

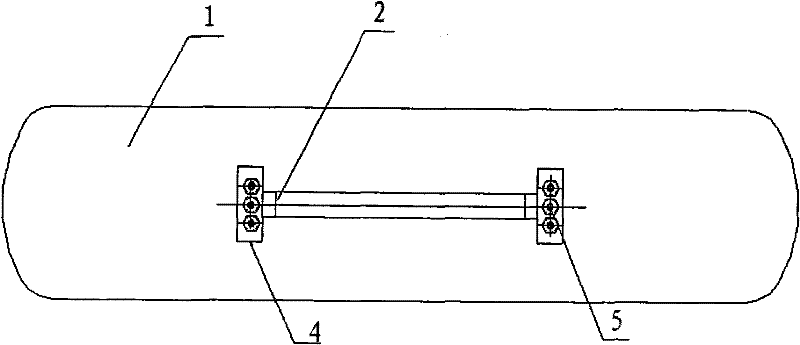

[0026] A generator magnetic pole coil inner diameter size detection device, in order to detect the calibration mold, including a calibration plate 1, a fixed handle 2, a lock nut 3, a pressure plate 4, and a fastening bolt 5, the calibration plate 1 has a fixed handle 2, fixed The handle 2 is fastened on the check plate 1 by the lock nut, the pressure plate 4 and the fastening bolt 5 . The verification board 1 is a 10mm thick glass cloth board with curved structures on both sides. After the production of a magnetic pole coil is completed, the verification board can be used for remanufacturing the magnetic pole coils of other products, which reduces the consumption of raw materials and improves the utilization rate of tooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com