Multi-source parallel confocal micro detection system

A detection system, confocal microscopy technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as limiting the scope of application, achieve the effect of expanding the scope of application, high-precision measurement, and overcoming the Taber effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

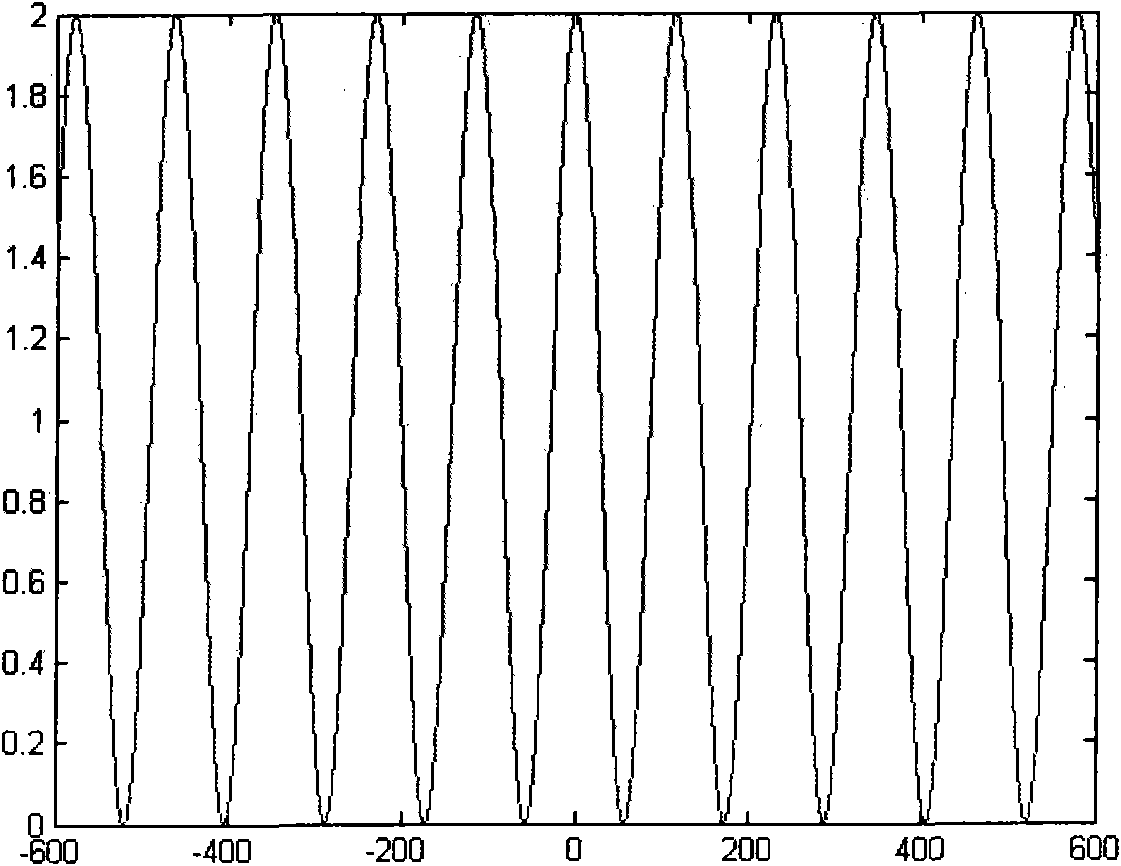

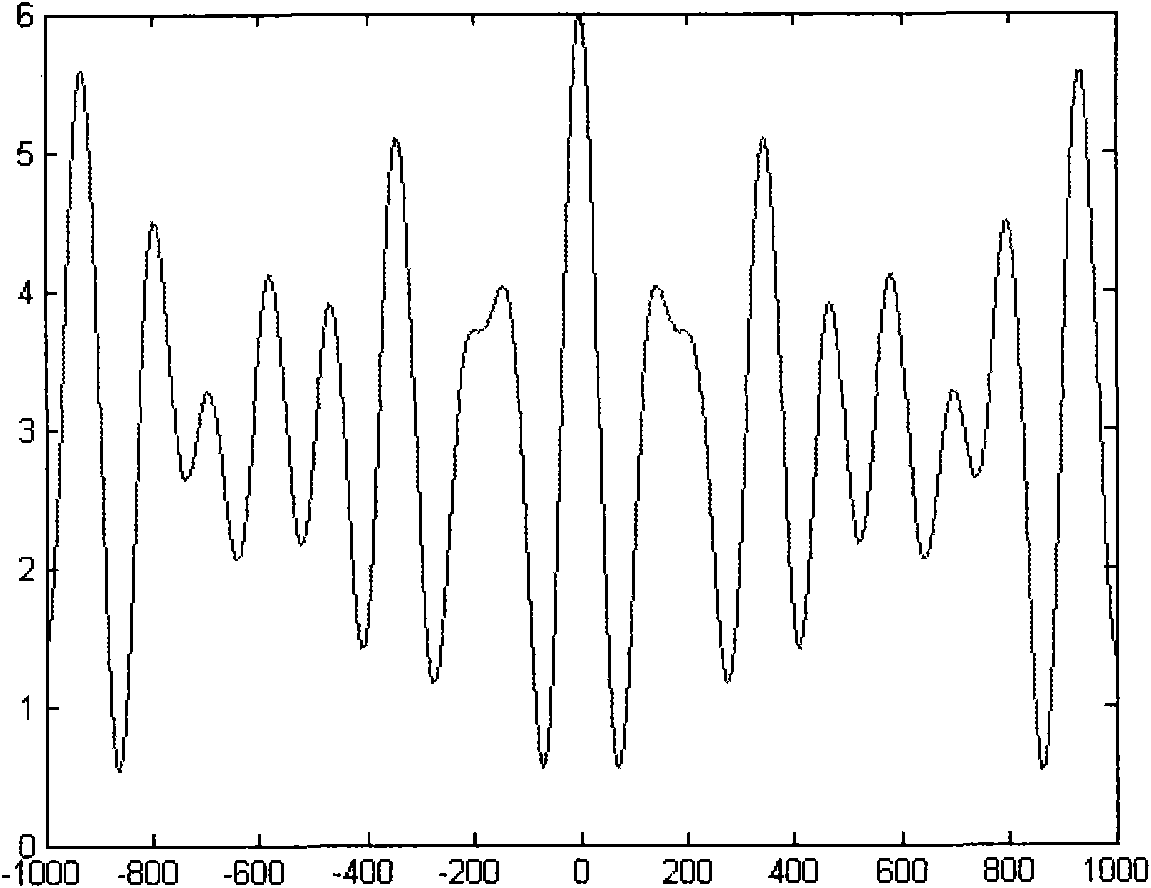

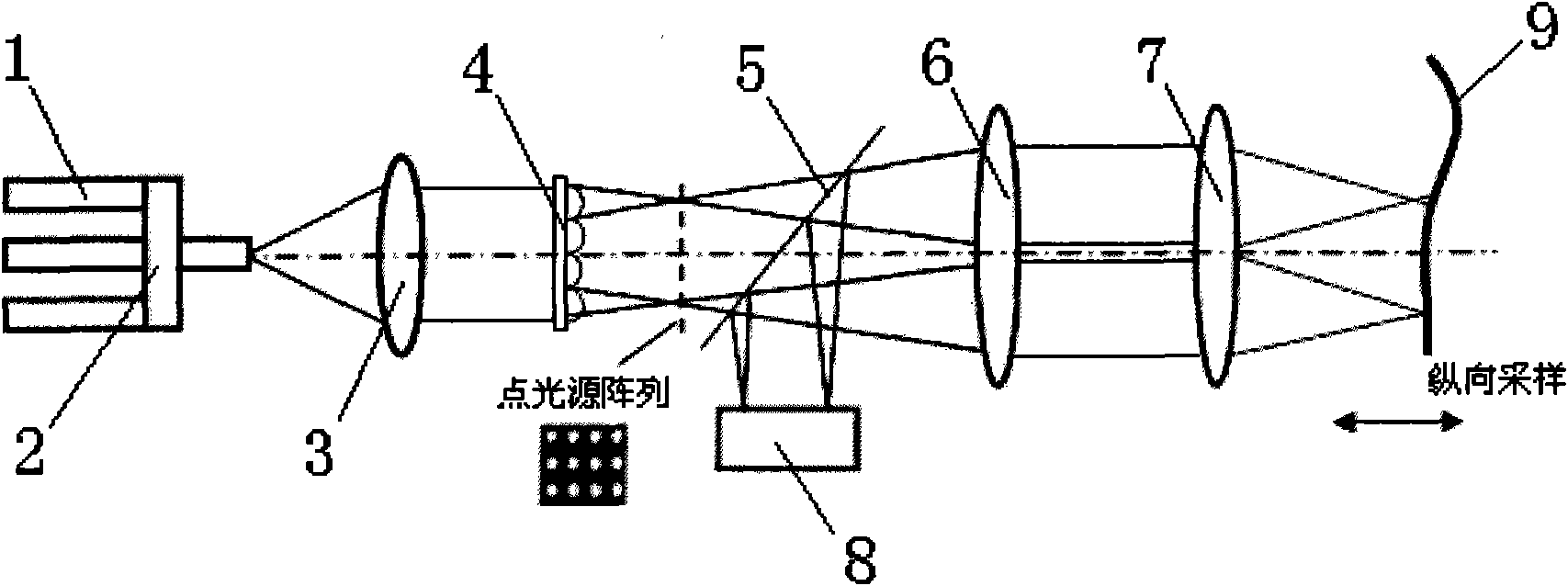

[0014] Multi-light source parallel confocal microscopic detection system, including three lasers 1, the wavelengths of the three lasers 1 are 650nm, 473nm and 405nm respectively, after the three lasers 1 are placed in parallel, a beam combiner 2 is installed at the light outlets of the three lasers 1 , the light emitted by the three lasers 1 enters the beam combiner 2, is combined by the beam combiner 2, and then exits from the light outlet of the beam combiner 2, and a collimating lens 3 is arranged in front of the beam combiner 2 light outlet, and the beam combiner The light outlet of 2 is located at the focus of one side of the collimating lens 3, and the other side of the collimating lens 3 is provided with a microlens array 4, the microlens array 4 is a 42×42 microlens array, and the aperture size of the microlens array 4 satisfies The parallel light after collimating lens 3 expands can be filled with microlens array 4, and the optical path front of microlens array 4 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com