Track testing apparatus of indoor small-size annular asphalt pavement structure

A technology of asphalt pavement and rutting test, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of long manufacturing and service cycle, limited loading conditions, complicated operation, etc., and achieves short service cycle and simple structure. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

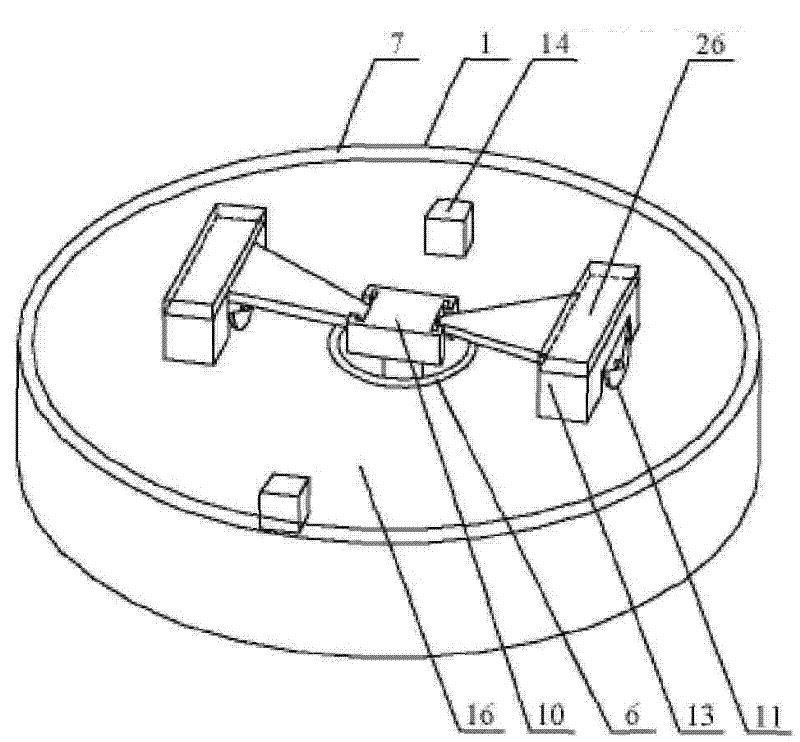

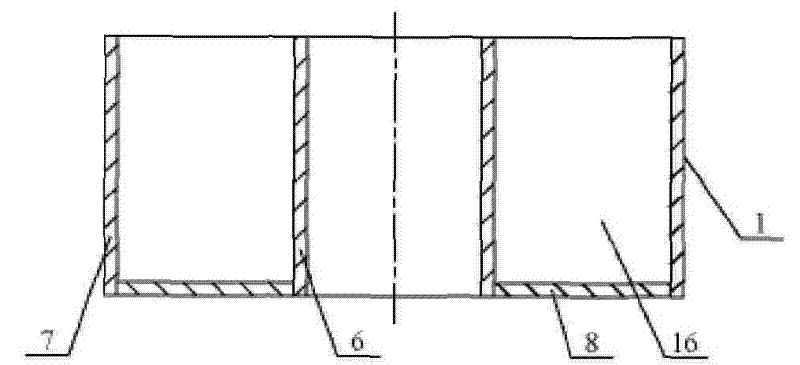

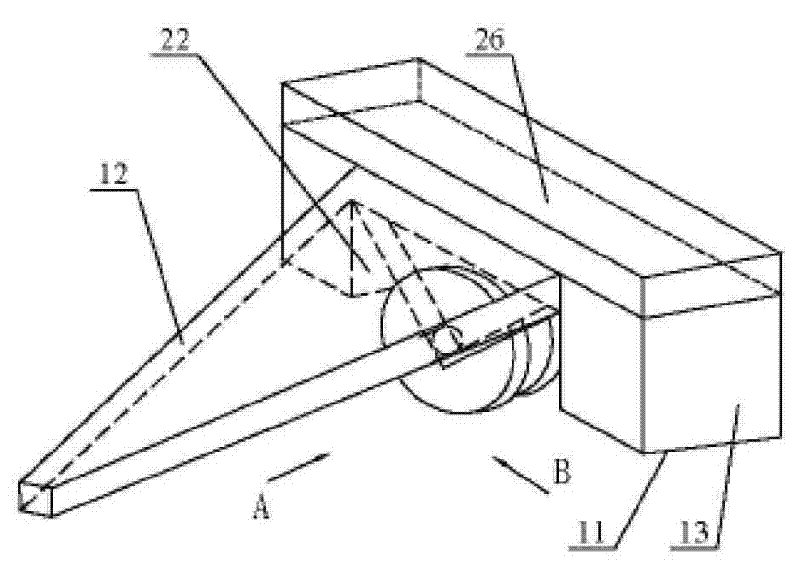

[0008] Specific implementation mode one: combine Figure 1-Figure 10 Illustrate this embodiment, the small-sized annular asphalt pavement structure loading test device of this embodiment is made up of test ring tank body 1, power unit 2, load application device, depth adjustment device 4 and measuring device; Said test ring tank body 1 is made up of The inner sleeve 6, the outer sleeve 7 and the annular bottom plate 8 are composed, the power device 2 is composed of a motor 9 and a rotary joint 10, and the load applying device includes two test vehicles 11 and two connecting frames 12. The measurement The device is composed of two displacement gauges 14; the outer sleeve 7 is set on the inner sleeve 6, and the annular bottom plate 8 is arranged in the annular cavity between the outer sleeve 7 and the inner sleeve 6, and the annular bottom plate 8 and the inner sleeve The bottom end faces of the sleeve 6 and the outer sleeve 7 are affixed, and the area surrounded by the annular ...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 8-Figure 10 Describe this embodiment, the depth adjustment device 4 of this embodiment is made up of at least two roller sets and wheel frame 19; Each roller set is made up of two rollers 20 and an axle 21, and described two rollers 20 are contained in axle 21 and is rotatably connected to the wheel shaft 21 through bearings. At least two roller groups are arranged in parallel from top to bottom. Each roller 20 is rollingly matched with the inner wall of the guide chute 18. The wheel shaft 21 is fixedly connected to the wheel frame 19. Each connecting frame The other end of 12 is affixed with wheel frame 19. So arranged, when the wheel 23 and the test asphalt mixture road produce rutting, the wheel 23 can sink, and the connecting frame 12 is kept horizontal all the time by the roller 20 rolling up and down in the guide chute 18 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 9 Describe this embodiment: the number of roller sets in this embodiment is three. With such a setting, the overall stability is good. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com