Minitype single-chip LCOS projection optical engine

A projection optical machine and single-chip technology, applied in the field of optical instruments, can solve the problems of reducing the heat of the system and the reliability of the whole machine, reducing the energy utilization efficiency of the light source, and lack of shaping measures for the lighting beam, so as to improve the image clarity , weight reduction, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

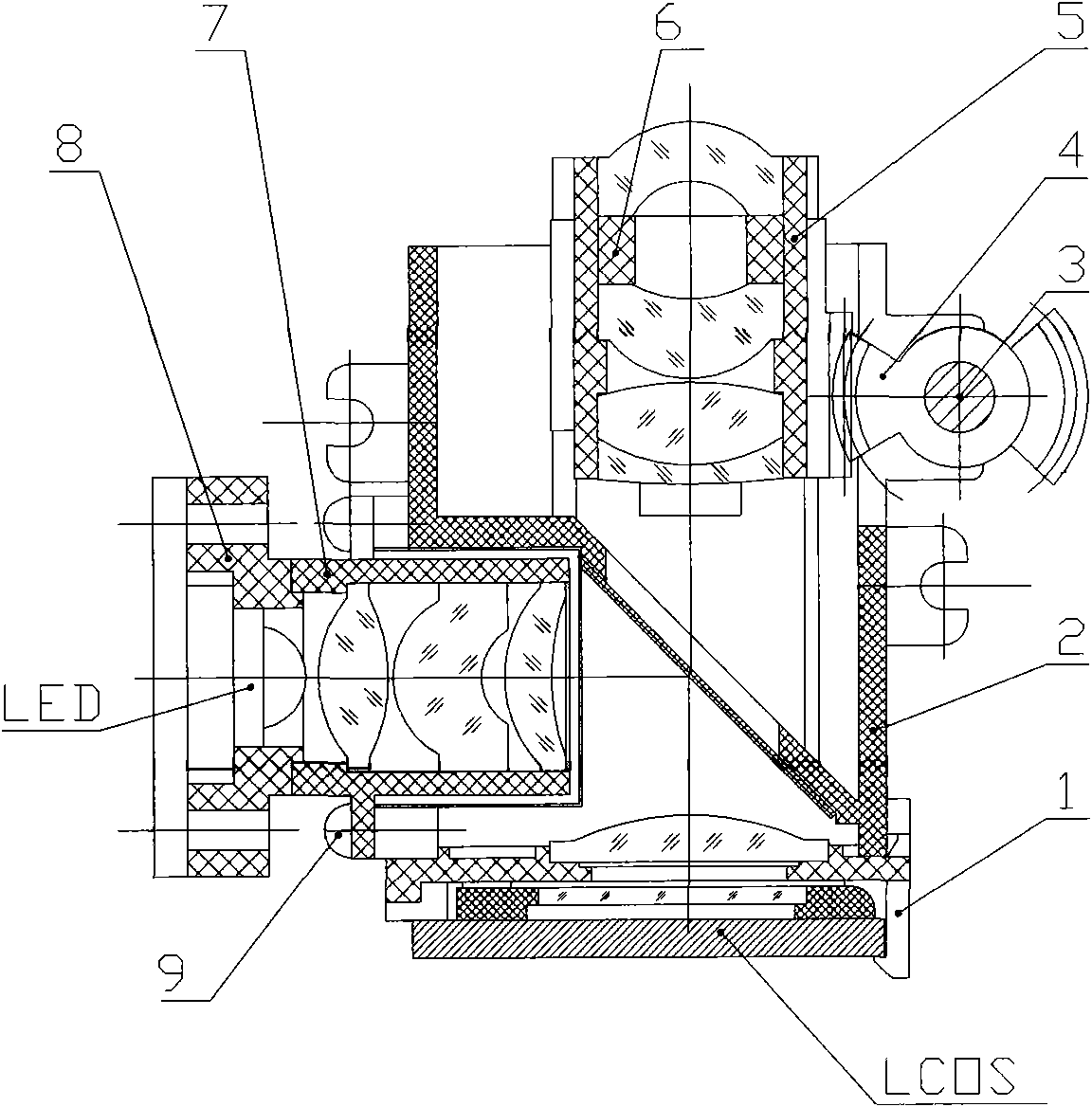

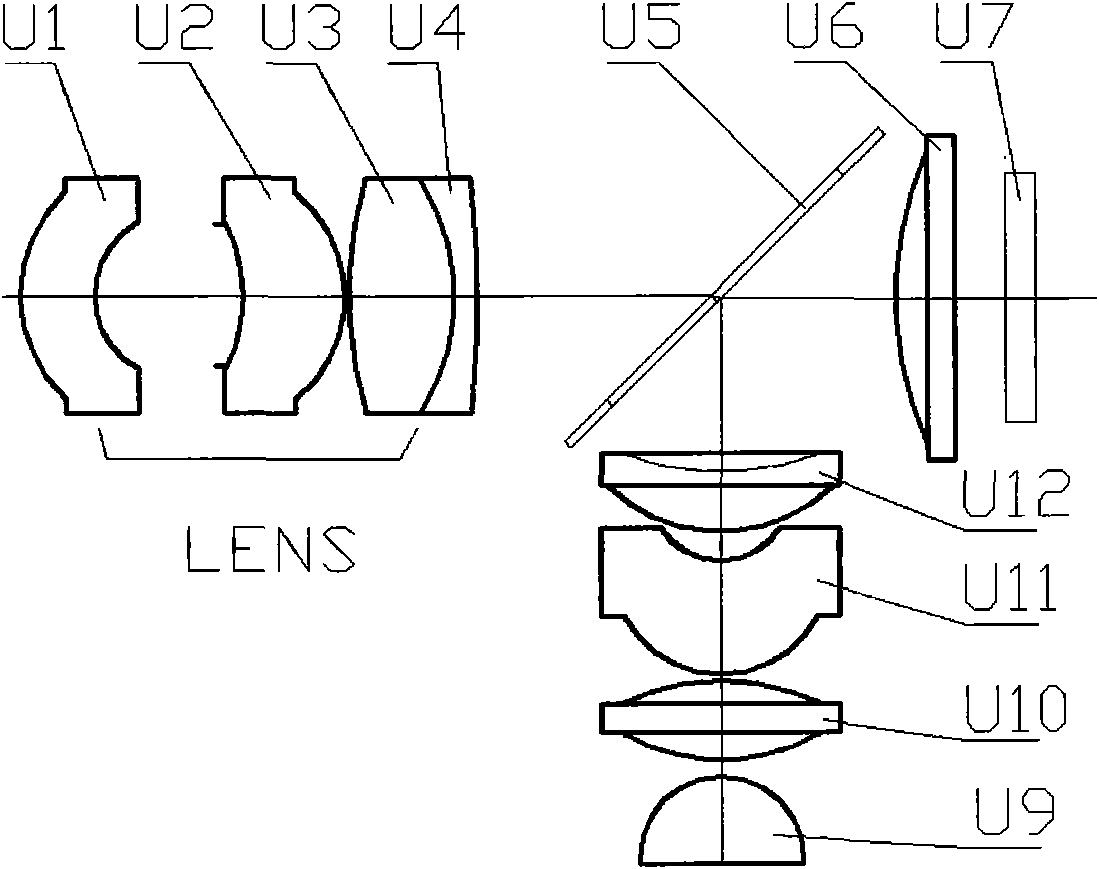

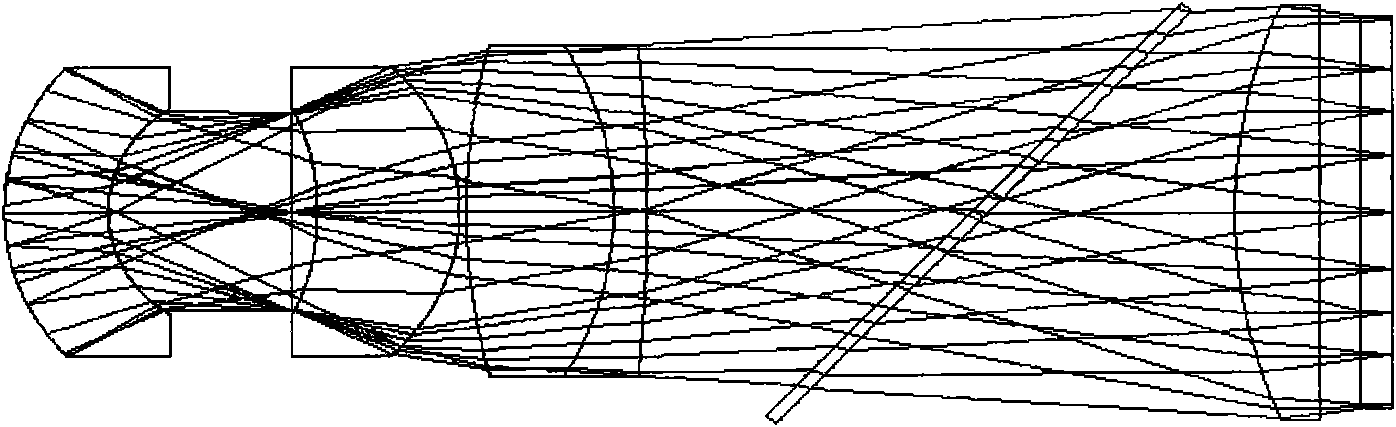

[0023] Such as figure 1 , 2The shown miniature single-chip LCOS projection optical machine is composed of an illumination system, a PBS beam splitter, a field lens, an LCOS chip and a projection lens. The lighting system is arranged on the lighting seat 7, and the projection lens [LENS], PBS beam splitter [U5], field mirror [U6] and LCOS chip [U7] are arranged along the imaging optical axis of the system from the screen side to the image plane side in order Arrangement; PBS beam splitter [U5] forms an included angle of 45 degrees with the imaging optical axis; the lighting system consists of LED light source, lens [U9], first condenser lens [U10], cylindrical lens [U11], second condenser lens [U12] ] are arranged sequentially along the optical axis of the lighting system. The optical axis of the lighting system is 90 degrees to the optical axis of the imaging optical path. The bending direction of the cylindrical lens [U11] is consistent with the direction of the lighting bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com