Method and device for preparing hydrogen by using fuel

A hydrogen and fuel technology, applied in steam engine installations, manufacturing combustible gases, chemical instruments and methods, etc., can solve problems such as ecological environment damage, achieve the effect of light content and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for producing hydrogen from coal, characterized in that iron or iron oxides are placed in an air reactor fluidized bed, fluidized air is introduced at the lower end A of the air reactor fluidized bed, and the operating temperature of the air reactor fluidized bed can be Controlled at about 800°C ~ 1250°C, iron or iron oxide reacts with oxygen in the air to obtain Fe 2 o 3 , and then the gas-solid two-phase is separated by the separator, and the separated air is discharged from the upper end H of the separator and can be used for power generation or waste heat utilization. The separated Fe 2 o 3 It enters the upper layer of the fuel reactor through the first overflow tank, and the operating temperature of the fuel reactor can be controlled at about 800 ° C ~ 1200 ° C. In the upper layer of the fuel reactor, some Fe 2 o 3 React with the incompletely reacted synthesis gas in the lower layer to convert to Fe 3 o 4 , and convert the synthesis gas into a carbon ...

Embodiment 2

[0040] A method for producing hydrogen from natural gas, characterized in that iron or iron oxides are placed in an air reactor fluidized bed, fluidized air is introduced at the lower end A of the air reactor fluidized bed, and the operating temperature of the air reactor fluidized bed is It can be controlled at about 800 ° C ~ 1250 ° C, and iron or iron oxides react with oxygen in the air to obtain Fe 2 o 3 , and then the gas-solid two-phase is separated by the separator, and the separated air is discharged from the upper end H of the separator and can be used for power generation or waste heat utilization. The separated Fe 2 o 3 Enter the upper layer of the fuel reactor through the first overflow tank 2, and the operating temperature of the fuel reactor can be controlled at about 800 ° C ~ 1200 ° C. In the upper layer of the fuel reactor, some Fe 2 o 3 React with the incompletely reacted gaseous fuel (natural gas or petroleum gas) in the lower layer to convert to Fe 3 o ...

Embodiment 3

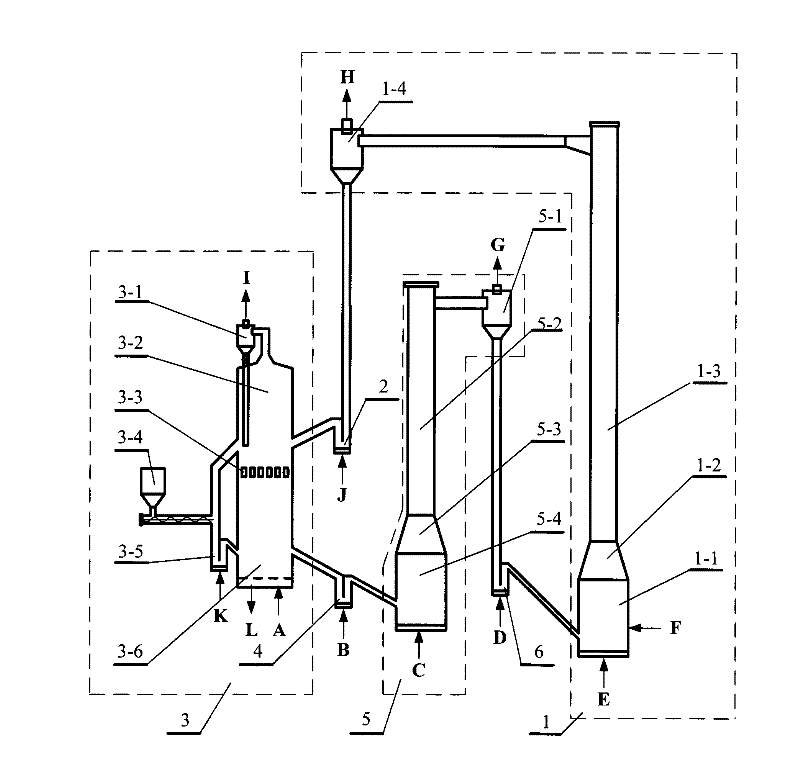

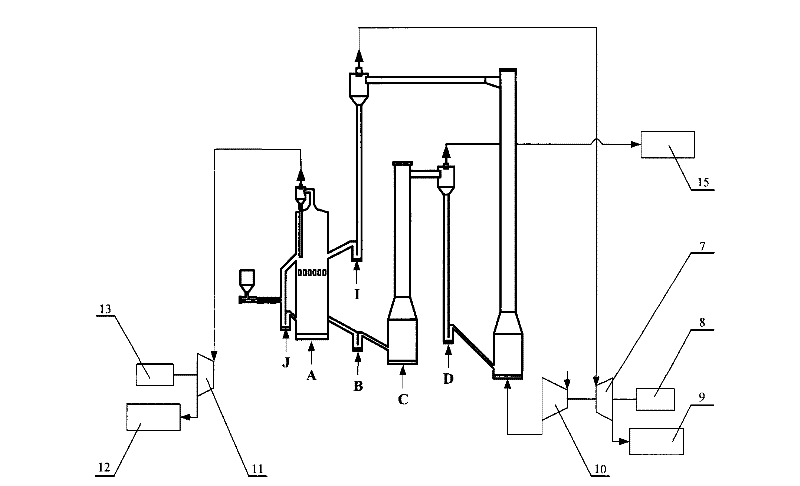

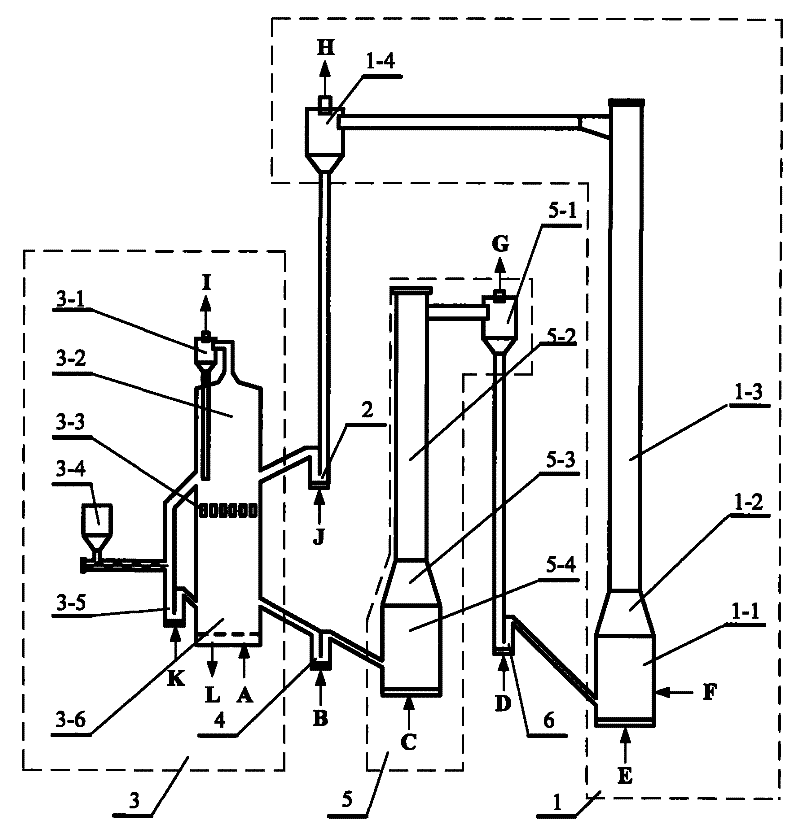

[0042] A method for producing hydrogen using fuel, a device for implementing the method for producing hydrogen using fuel according to claim 1, comprising an air reactor fluidized bed 1, a first overflow tank 2, a fuel reactor 3, The second overflow tank 4, the hydrogen production reactor fluidized bed 5, and the third overflow tank 6 are composed. The upper end of the air reactor fluidized bed 1 is connected with an oxygen-deficient air separator 1-4, and an oxygen-deficient air separator 1 The lower end of -4 is connected to the upper layer 3-2 of the fuel reactor through the first overflow tank 2. The fuel reactor includes a fluidized bed, and an intermediate air distribution plate 3-3 is arranged in the fluidized bed and the intermediate air distribution plate The plate 3-3 divides the fluidized bed into the upper layer 3-2 of the fuel reactor and the lower layer 3-6 of the fuel reactor, and an overflow pipe 3 is arranged between the upper layer 3-2 of the fuel reactor and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com