Production method of glucolactone

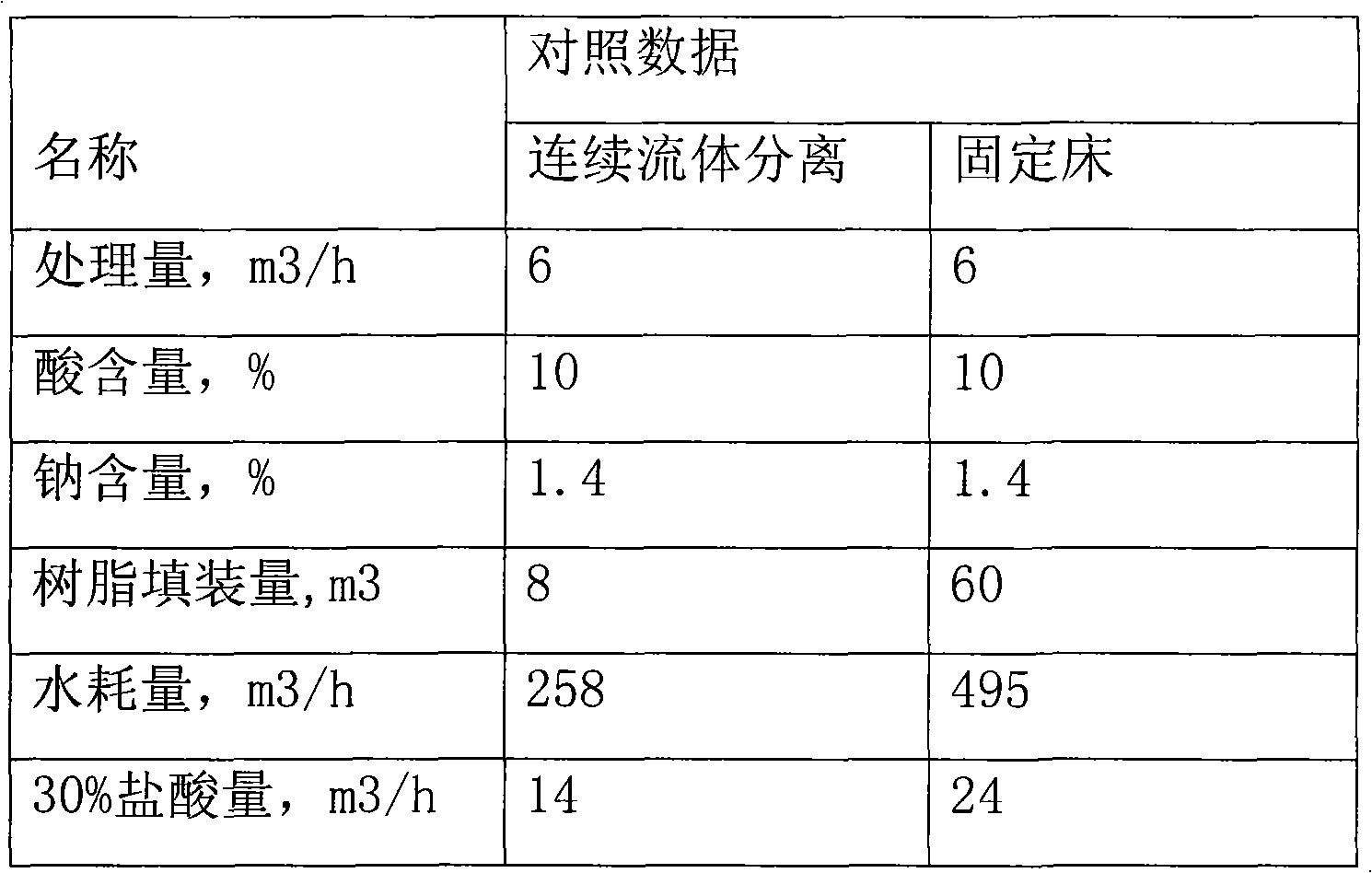

A technology of gluconolactone and a production method, which is applied in the production field of gluconolactone, can solve the problems of serious pollution, high resin consumption and high energy consumption, and achieves the effects of high concentration ratio, improved quality and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Describe in detail below in conjunction with accompanying drawing and implementation example:

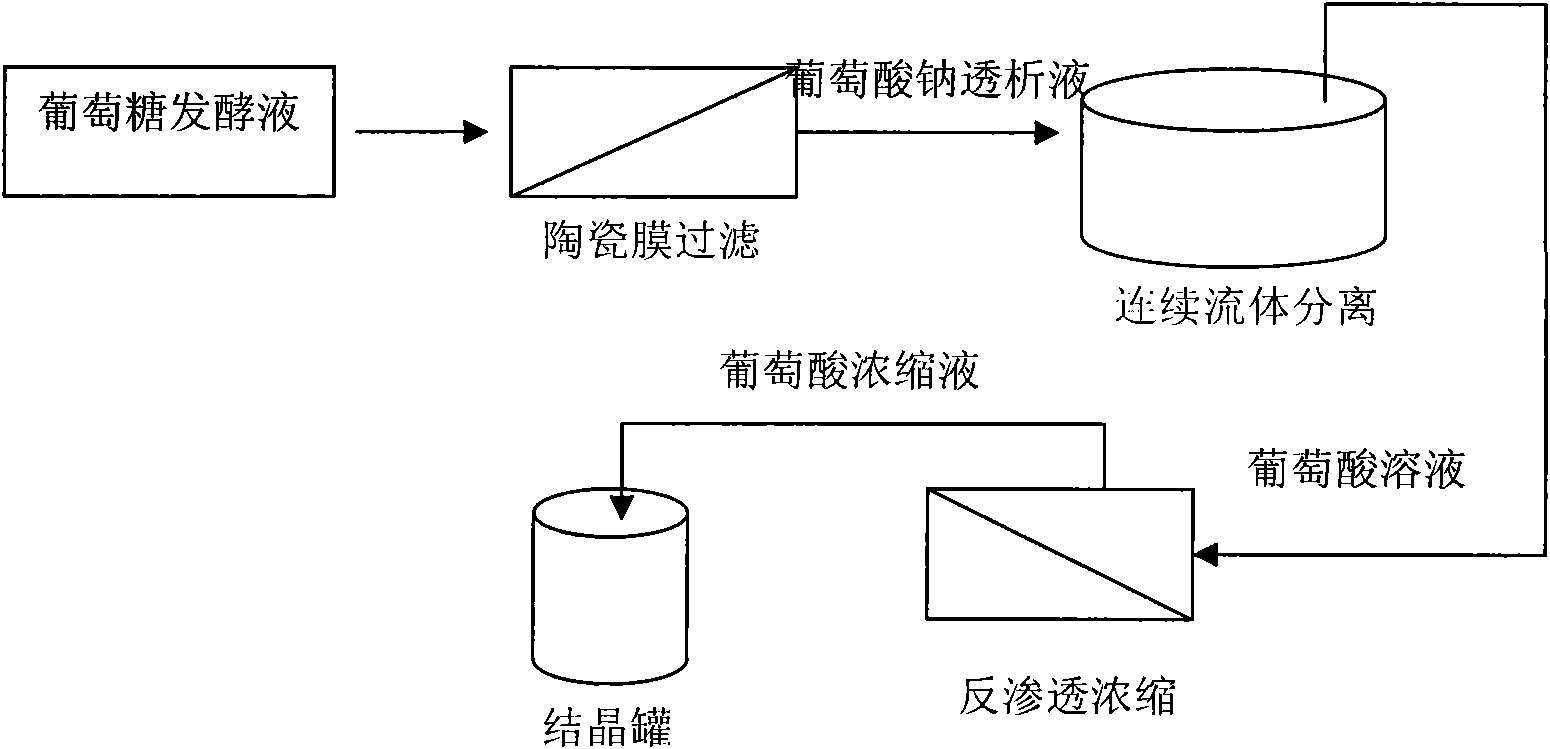

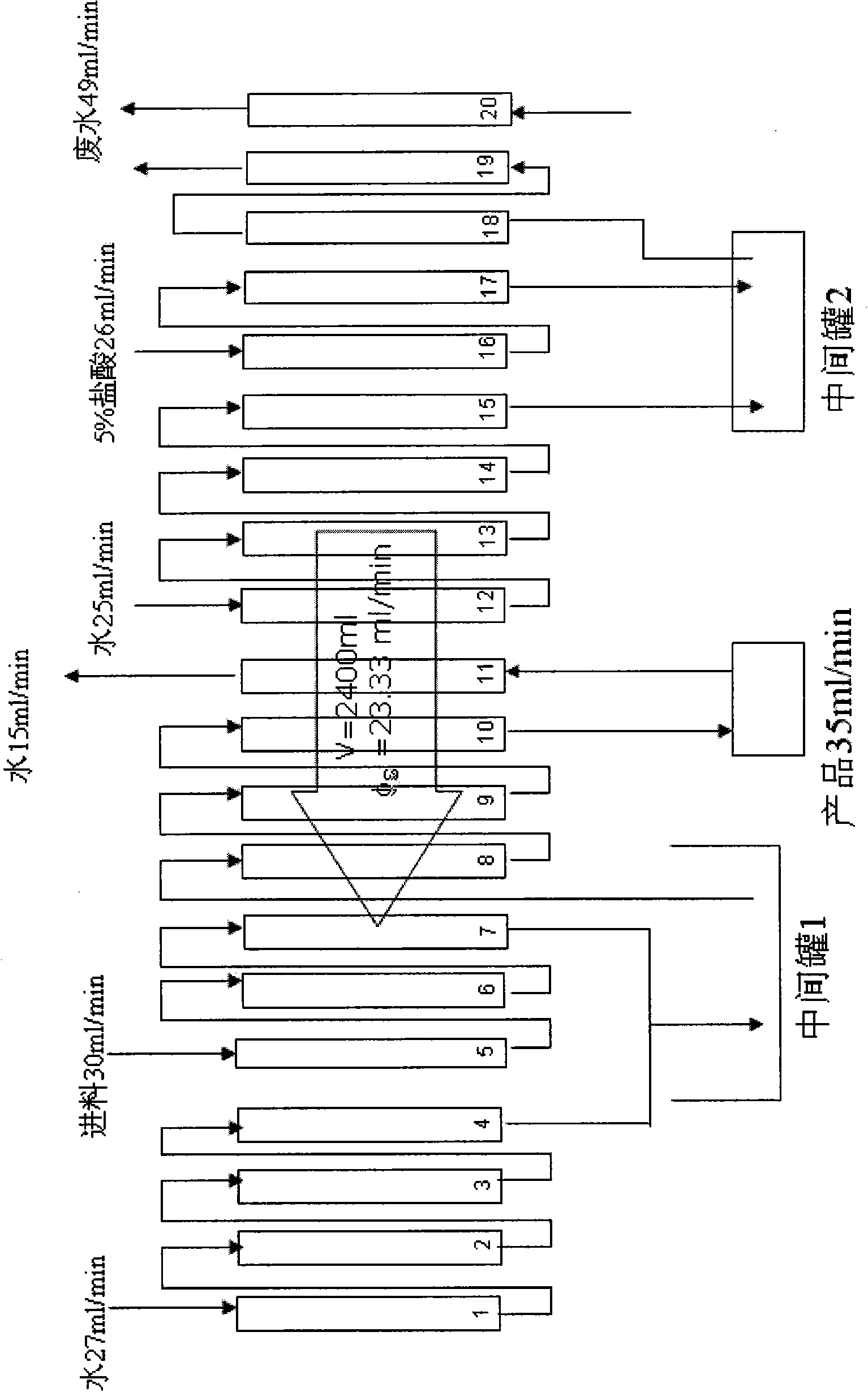

[0043] First filter the fermentation liquid containing sodium gluconate through a ceramic membrane, and then pass the continuous fluid separation device for continuous ion exchange to convert the sodium gluconate into gluconic acid solution, and then concentrate the gluconic acid solution through reverse osmosis to obtain gluconic acid concentrate. Add gluconolactone seed crystals to generate gluconolactone crystals in the concentrated solution (see figure 1 ). The specific operation process is as follows:

[0044] 1. Ceramic membrane filtration

[0045] The feed liquid used is gluconic acid fermentation liquid, the pore size of the ceramic membrane is 50nm, the temperature is 30°C, and the pressure is 0.3Mpa. A total of 3 batches of experiments have been carried out. The specific results are shown in Table 1:

[0046] the batch

when filtering

Room / h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com