Novel electric directional coring apparatus

A corer and electric technology, which is used in the extraction of undisturbed core devices, measurement, wellbore/well components, etc., can solve the problems of restricting the popularization and application of directional coring technology, difficult assembly and disassembly, and complex structure, so as to reduce the cutting work. reduce power consumption, reduce the impact of mechanical compartment seals, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

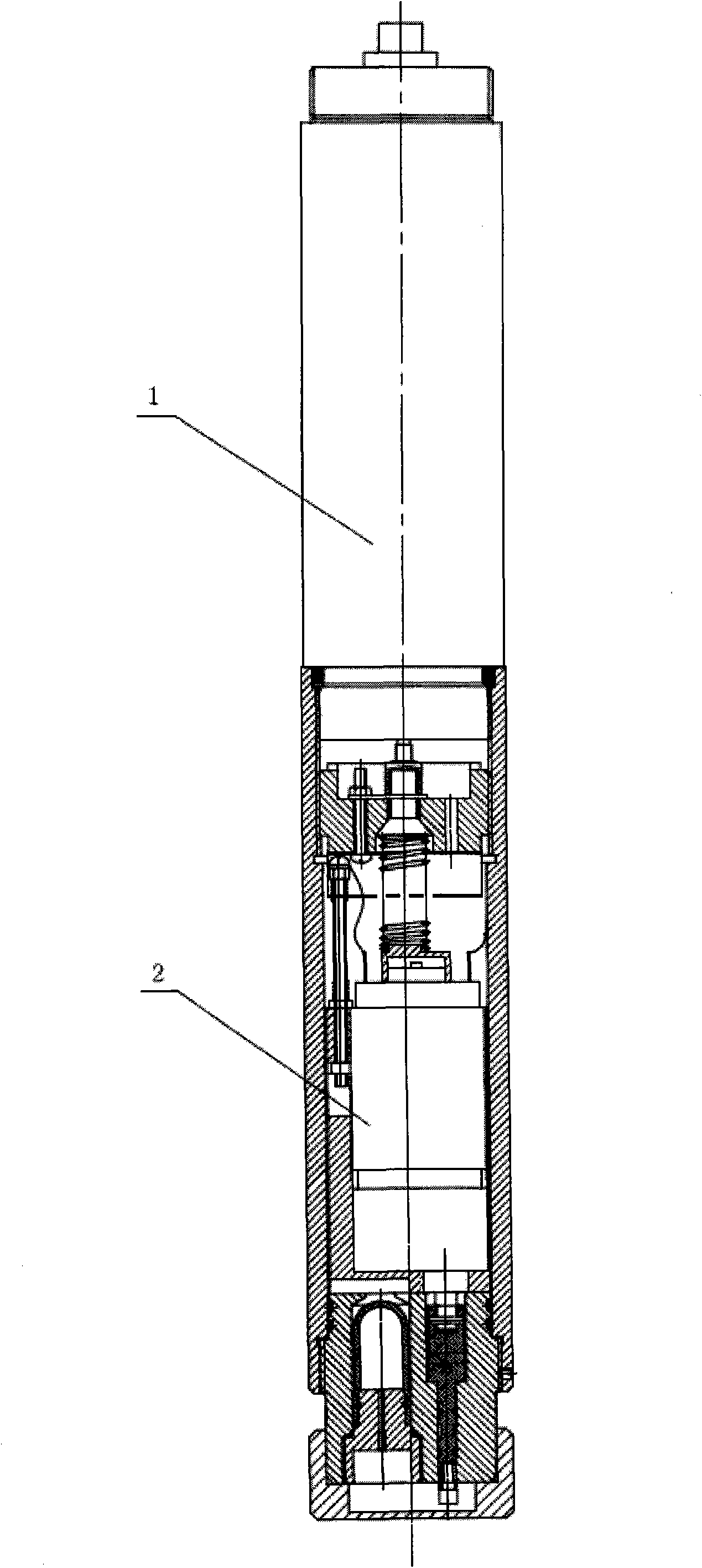

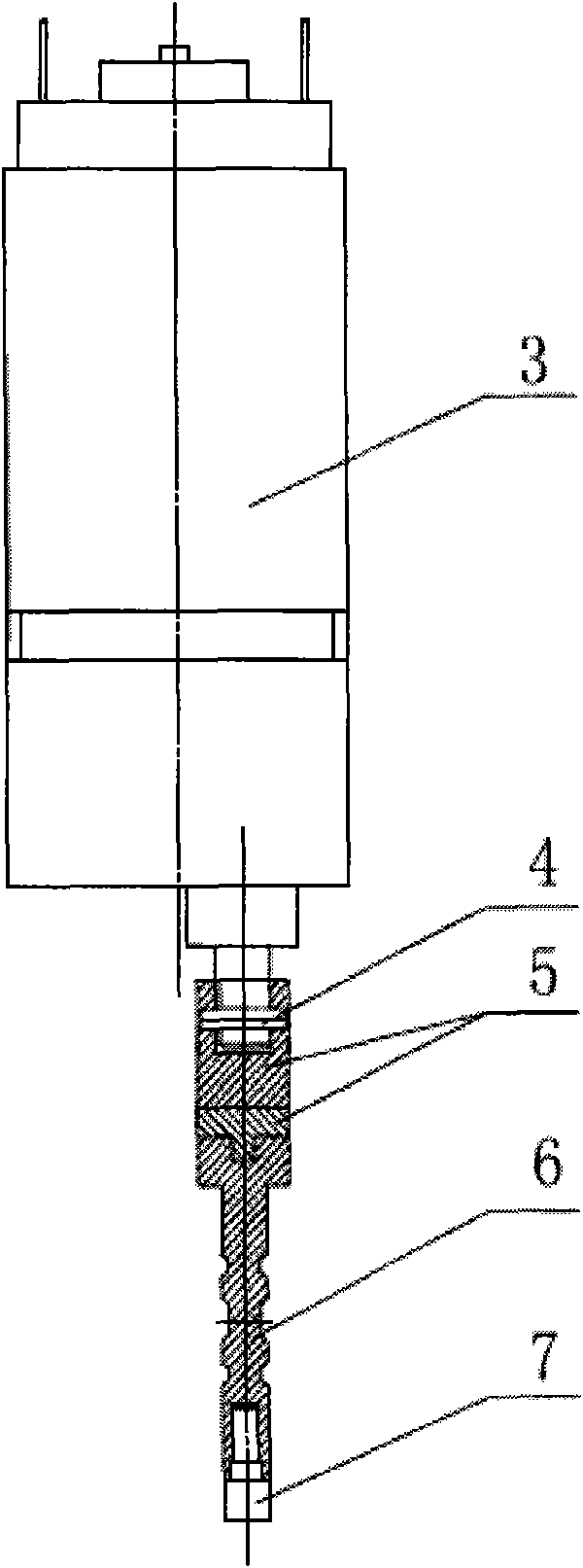

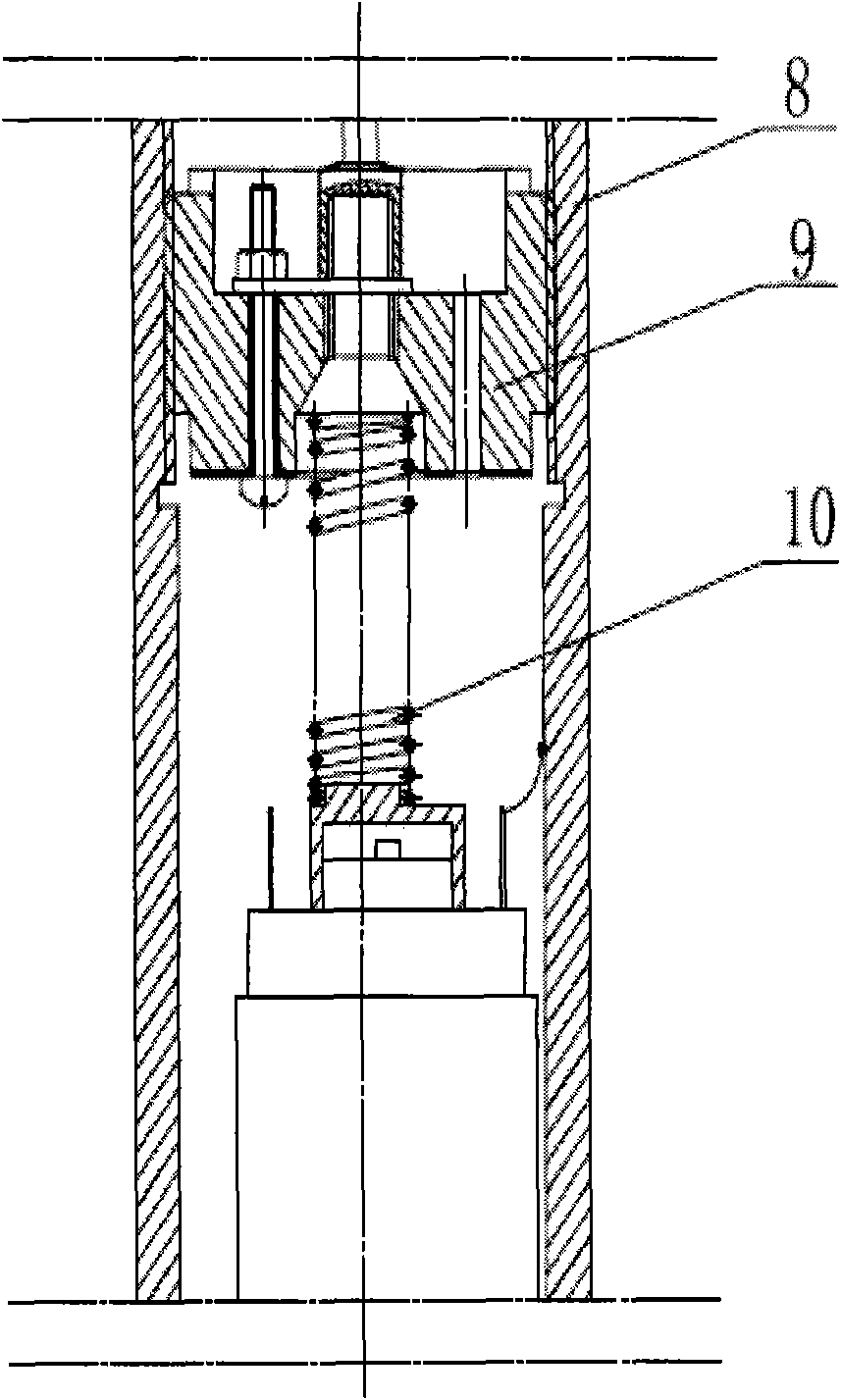

[0029] This design consists of the following components:

[0030] Battery compartment 1, Mechanical compartment 2, Motor 3, Pin shaft 4, Coupling 5, Shaft 6, Drill bit 7, Sleeve 8, Electrode seat 9, Spring 10, Guide column 11, Support nut 12, Pressure balance sleeve 13, Balance nut 14, electrode connecting column 15, conductive copper ring 16, slotted round head screw 17, switch spring 18, electrode holder 19, backflow channel 20.

[0031] When the diamond micro-drill (7) in the directional marking device did not touch the end face of the rock core, the screw (17) as a switch control did not contact the conductive copper ring (16), the whole circuit was disconnected, and the motor (3) did not work; when the micro-drill (7) is in contact with the end face of the rock core, the micro-drill (7), the shaft (6), and the motor (3) move up together, and the screw (17) is driven by the electrode holder (9) through the switch spring (18) Press it back in the guide groove of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com