Finned tube with water-bearing channel

A technology of finned tubes and water tanks, applied in the field of refrigeration equipment, can solve the problems of unusable evaporators and large losses, etc., and achieve the effects of eliminating electrical fires, reducing food dry consumption, and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

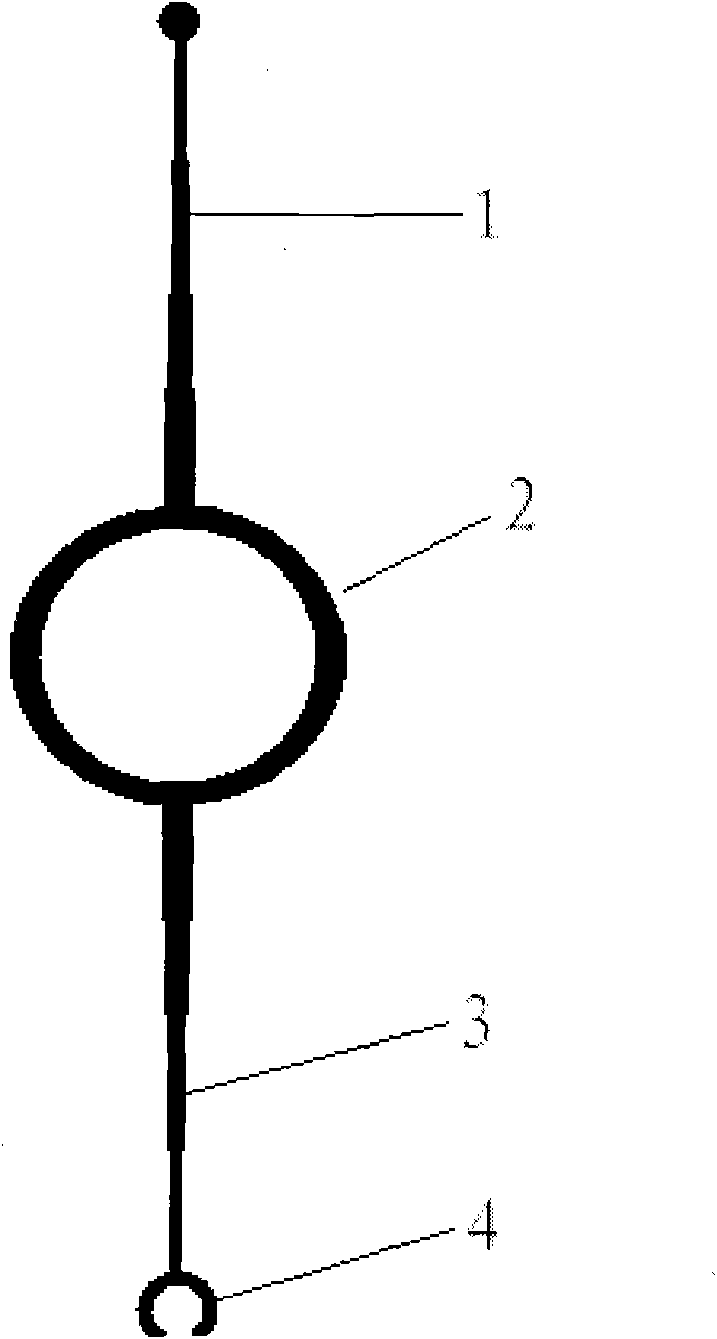

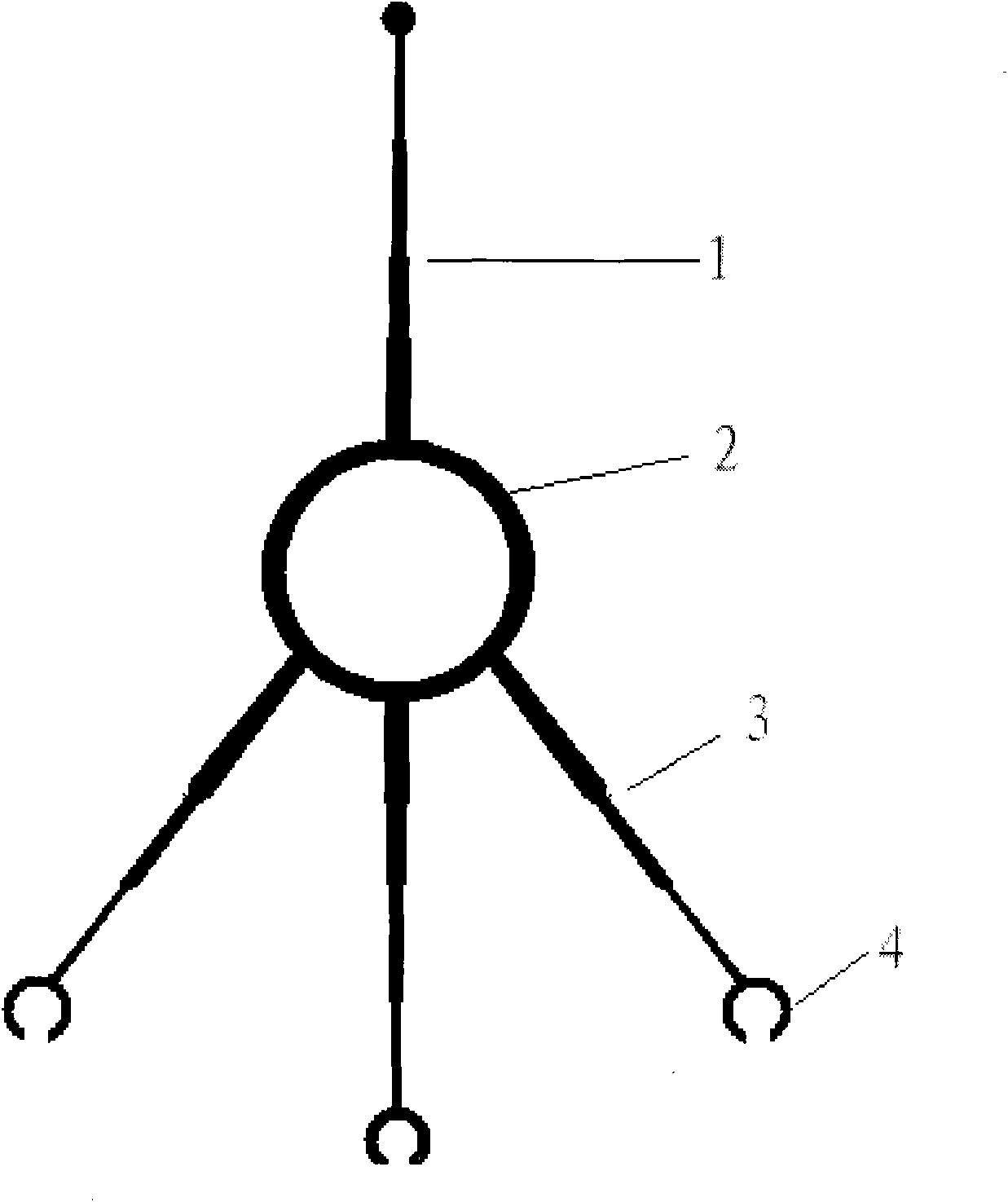

Image

Examples

Embodiment Construction

[0013] The row tube evaporator in the cold storage is connected to the refrigeration system in the form of a group during use. The refrigerant working medium is different, and the connection form of the row tube evaporator is different. The Freon system is used to multiple tubes in parallel, and the elbow is used to connect the serpentine. To achieve the purpose of dry evaporation. A small refrigeration system uses a set of coiled tubes, and a large refrigeration system uses multiple sets of coiled tubes. When used in an ammonia refrigeration system or a Freon flooded evaporation system, it is customary to connect multiple pipes in parallel to form a pipe group.

[0014] The row-tube evaporator composed of finned tubes with water tanks, when installing each group with a certain slope such as 2%, the condensed water of the finned evaporator will flow to the lower side through the water tanks, on this side Set up a water collection tank to lead the water out of the cold storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com