Portable cable fault detection high-voltage capacitor

A high-voltage capacitor and cable failure technology, applied in the field of capacitors, can solve the problems of large volume of high-voltage pulse capacitors, inconvenient for vehicles, labor and time-consuming, etc., and achieve the effects of simple wiring, high insulation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

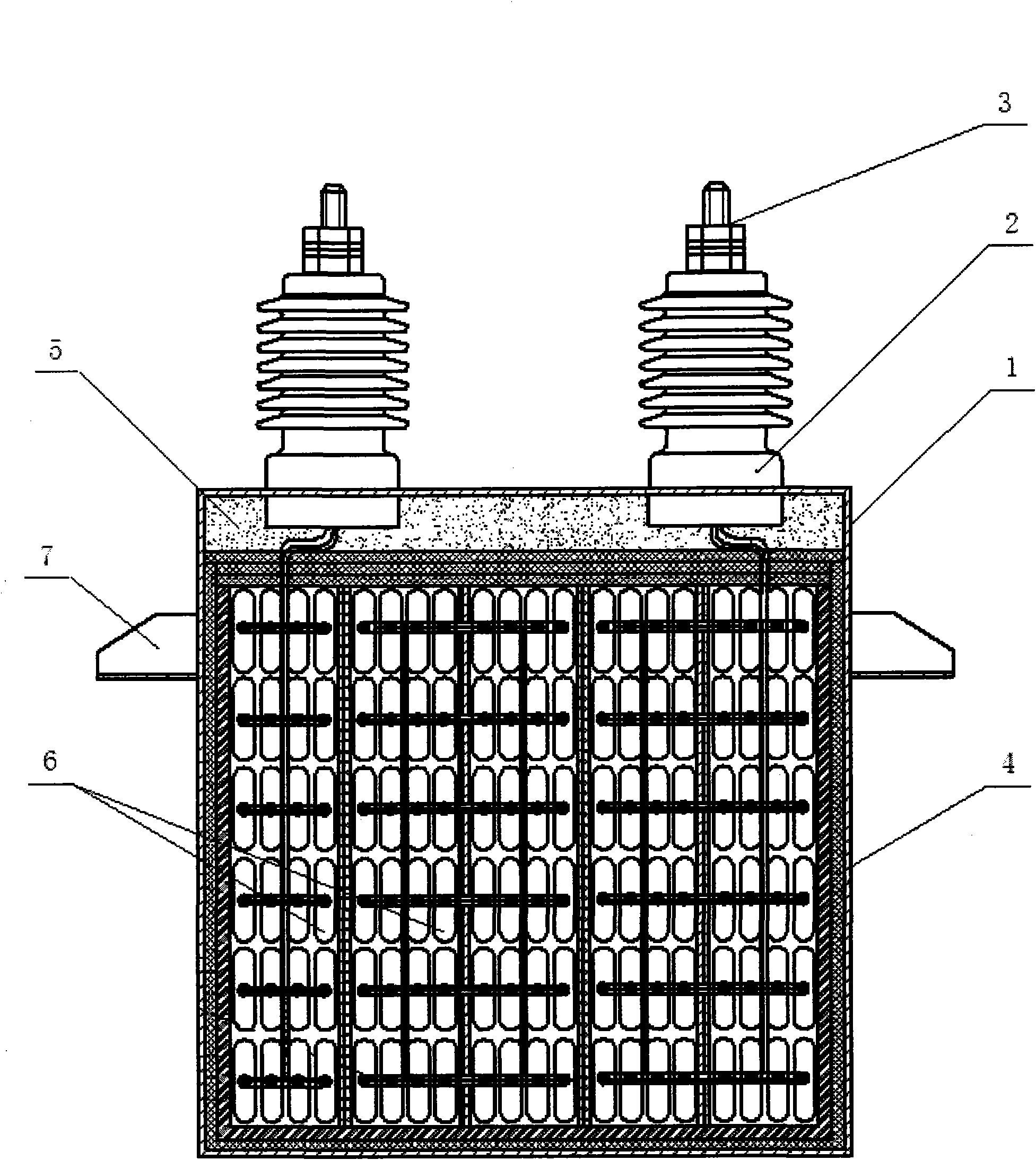

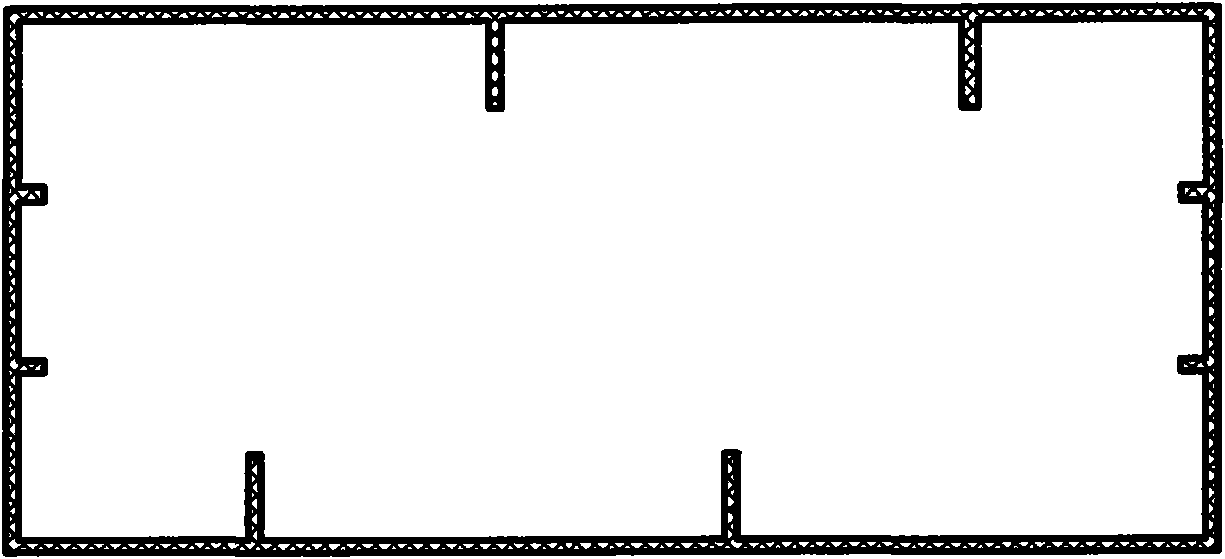

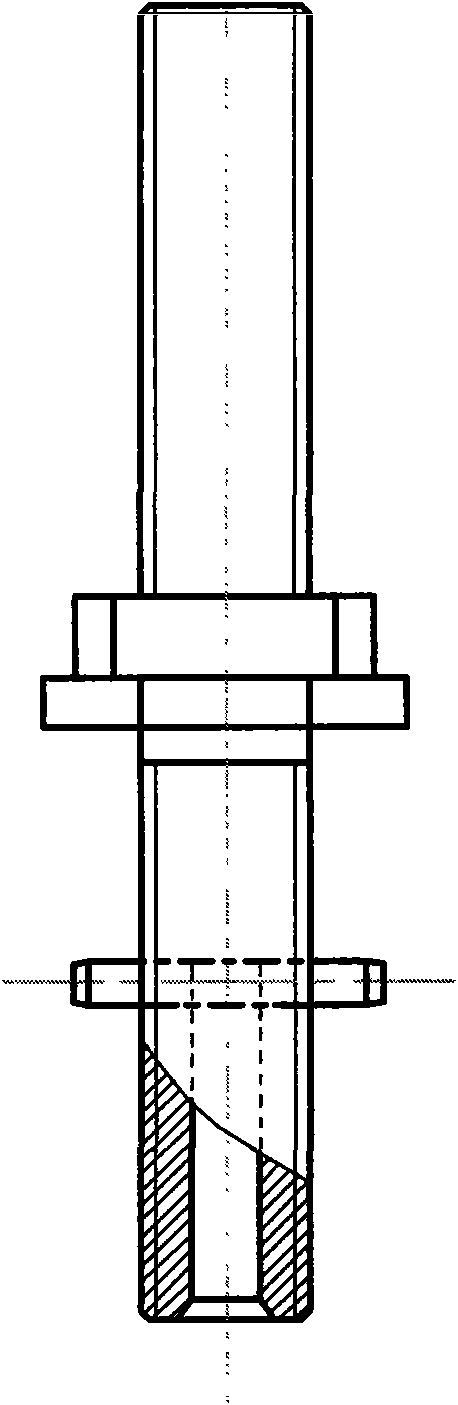

[0017] As shown in the figure, Embodiment 1: the present invention includes a housing 1, an insulator 2 disposed on the housing, and a lead post 3 disposed in the insulator 2, and is characterized in that: each capacitor core is arranged inside the housing. The capacitor core group 6 is provided with an insulating sheath 4 between the capacitor core group 6 and the housing 1, and insulating plates 8, 9, 10, 11 are arranged between each capacitor core group 6; each capacitor distributed side by side The cores form parallel cores that are connected together in parallel, and at the same time, the parallel cores are combined up and down to form each capacitor core group 6; in each capacitor core group 6, each capacitor core that forms the parallel core passes through the level The connecting pieces 12 are connected in parallel, and the horizontal connecting pieces 12 at the upper and lower positions are connected together through the vertical connecting pieces 13; between two adjac...

Embodiment 2

[0021] Embodiment 2: A capacitor core group 6 composed of five groups of capacitor cores is arranged inside the housing; in each group of capacitor core groups 6, every four capacitor cores are distributed side by side to form parallel cores, and are connected in parallel The cores are arranged up and down in at least five rows, and the front and rear end surfaces of every four capacitor cores are respectively provided with connecting copper strips. Connected up and down through the vertical copper connecting piece; the vertical copper connecting piece on the front face of the first group of capacitor cores is connected to the lead post through tinned copper wires, and the front face of the first group of capacitor cores consists of 20 capacitor cores The four parallel cores on the rear end face of the first group of capacitor cores share the same connection copper strip and are directly connected to the four parallel cores on the rear end face of the second set of capacitor co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap