Method for compensating critical dimension

A technology of critical dimension and compensation method, applied in the field of exposure compensation, to achieve the effect of solving compatibility and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

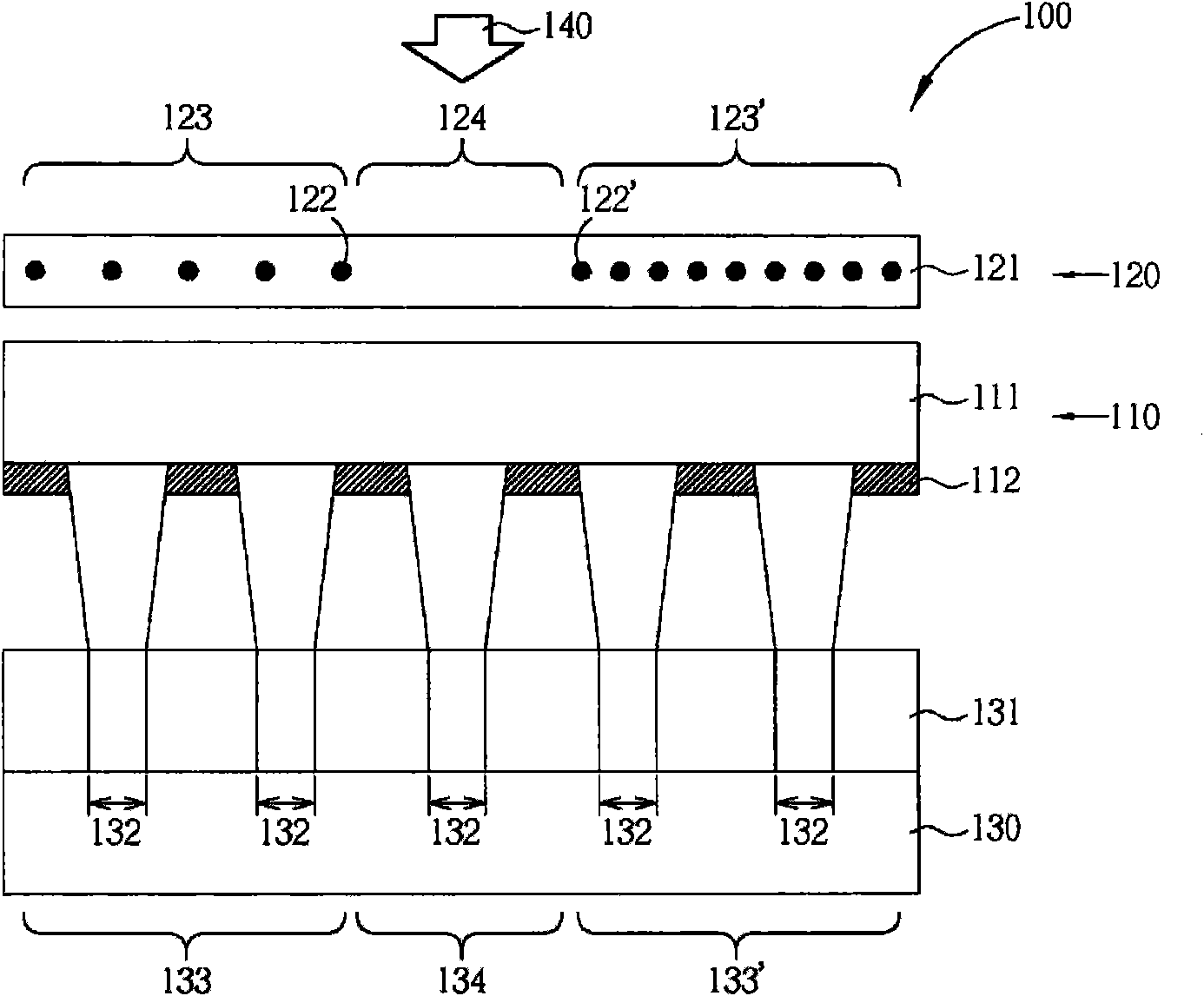

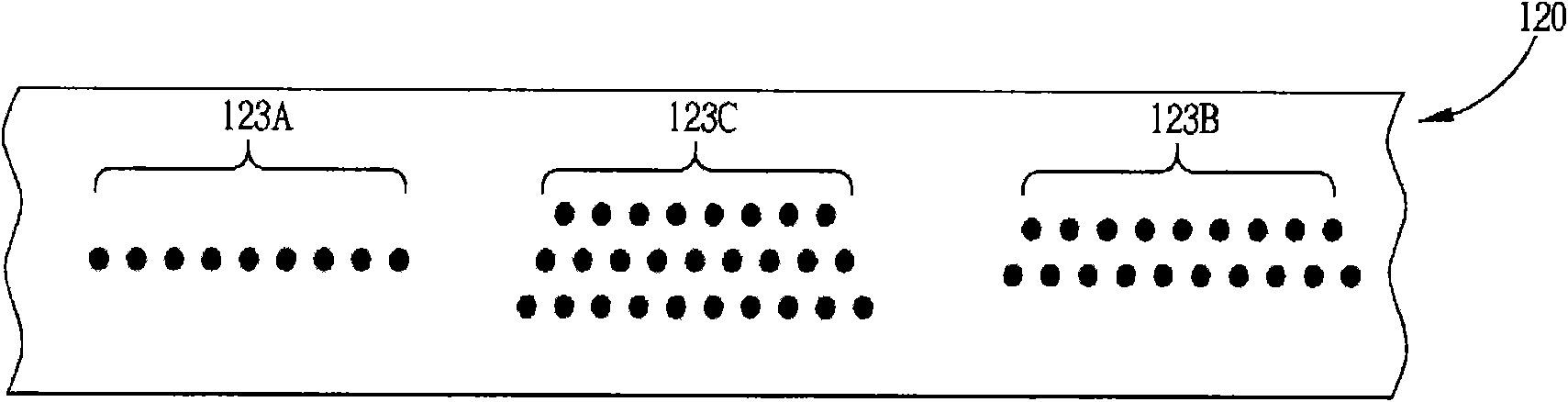

[0023] The present invention first proposes an exposure assembly. figure 1 A preferred embodiment of the exposure unit of the present invention is illustrated. The exposure assembly 100 of the present invention includes a main photomask 110 and an auxiliary photomask 120 . The main photomask 110 includes a main transparent substrate 111 and a main pattern 112 , and the device layout pattern can be defined in the substrate 130 through the main photomask 110 . In general, the master photomask 111 may also be referred to as a product photomask. The main transparent substrate 111 is usually a glass substrate. The glass substrate needs to have a high transmittance to the exposure light source. Generally speaking, the glass substrate is usually made of quartz material. The main pattern 112 is located on one side of the main transparent substrate 111, and its function is to block the exposure light source to form a predetermined pattern on the photoresist, but it is easy to be etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com