Automatic cleaning method of pointed bristles of toothbrush

The technology of a pointed tip and a toothbrush is applied in the field of automatic cleaning of the toothbrush tip and filament, which can solve the problems of large waste of water resources, large space occupation, increased labor force, etc., so as to improve product quality, improve production efficiency, and reduce manual operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

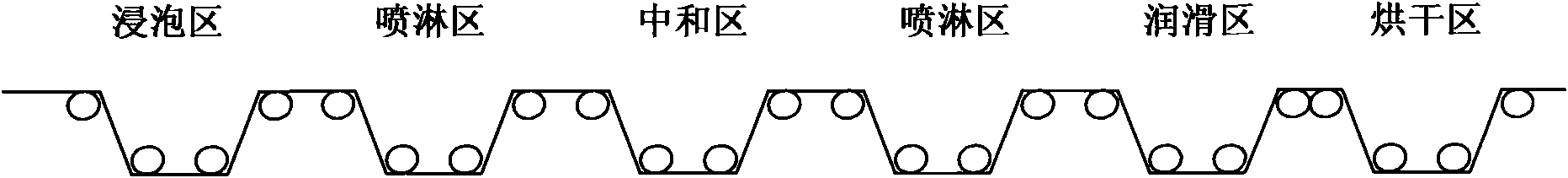

Image

Examples

Embodiment 1

[0018] 1) Do not untie the bundled toothbrush pointed brush filaments prepared, and place them directly in a immersion pool filled with 0.1% aqueous hydrochloric acid solution by mass percentage, keep the pointed direction of the filaments vertically upward, The liquid level of the aqueous hydrochloric acid solution is higher than the vertical height of the pointed brush wire of the toothbrush; the aqueous hydrochloric acid solution in the immersion pool is heated to a temperature of 40°C, and after 3 hours of heat preservation, the hydrochloric acid water solution is replaced for another 2 hours of heat preservation;

[0019] 2) Send the toothbrush pointed brush wire soaked in step 1) into the cleaning pool through a conveyor belt with a transmission speed of 0.2m / min, and at the same time perform ultrasonic cleaning on the toothbrush pointed brush wire in the cleaning pool according to the quality requirements. The frequency is 2.5KHZ, so that the oil stains, dirt, fine parti...

Embodiment 2

[0025] 1) Do not untie the bundled toothbrush pointed brush filaments prepared, and directly place them in a immersion pool filled with a hydrochloric acid aqueous solution with a concentration of 15% in mass percentage, keep the pointed direction of the filaments vertically upwards, and the immersion pool The liquid level of the hydrochloric acid aqueous solution is higher than the vertical height of the pointed brush wire of the toothbrush; the hydrochloric acid aqueous solution in the immersion pool is heated to a temperature of 80° C., and the hydrochloric acid aqueous solution is replaced after 30 minutes of heat preservation;

[0026] 2) Send the toothbrush pointed brush wire soaked in step 1) into the cleaning pool through a conveyor belt with a transmission speed of 8m / min, and at the same time perform ultrasonic cleaning on the toothbrush pointed brush wire in the cleaning pool according to the quality requirements. It is 200KHZ, so that the oil stains, dirt, fine part...

Embodiment 3

[0032] 1) Do not untie the bundled toothbrush pointed brush filaments prepared, and directly place them in a immersion pool filled with 8% hydrochloric acid aqueous solution with a concentration of 8% by mass, keep the pointed direction of the filaments vertically upward, and the The liquid level of the aqueous hydrochloric acid solution is higher than the vertical height of the pointed brush wire of the toothbrush; the aqueous hydrochloric acid solution in the immersion pool is heated to a temperature of 60°C, and the aqueous hydrochloric acid solution is replaced after 1 hour of heat preservation for another 2 hours of heat preservation;

[0033] 2) Send the toothbrush pointed brush wire soaked in step 1) into the cleaning pool through a conveyor belt with a transmission speed of 3m / min, and at the same time perform ultrasonic cleaning on the toothbrush pointed brush wire in the cleaning pool according to the quality requirements. It is 100KHZ, so that the oil stains, dirt, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com