Method for producing and assembling superheater coil tubes of steam generators

A technology for steam generators and serpentine tubes, applied in the field of superheater serpentine tubes for manufacturing and assembling steam generators, to achieve the effect of eliminating influence and flawless precipitation hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

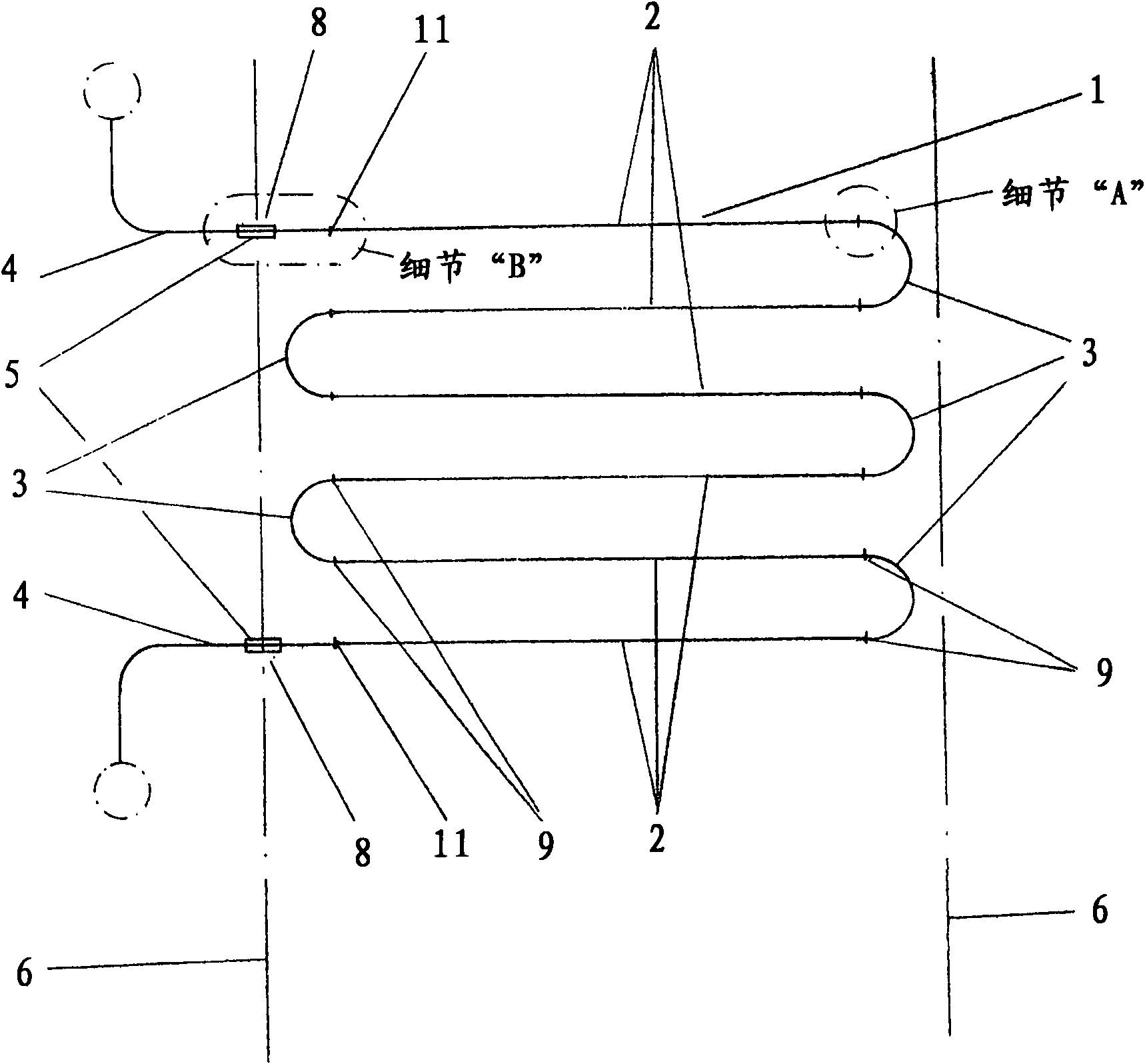

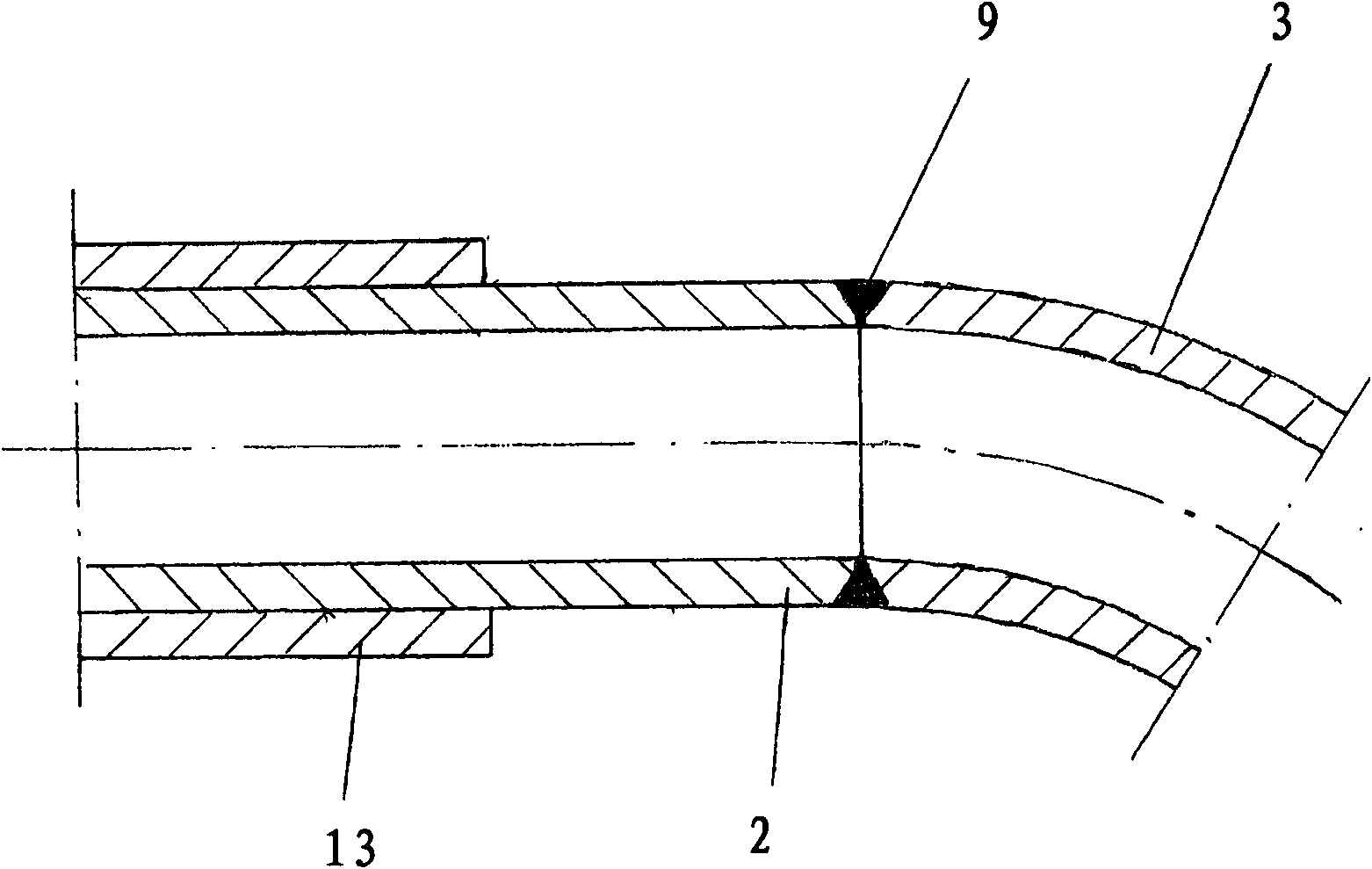

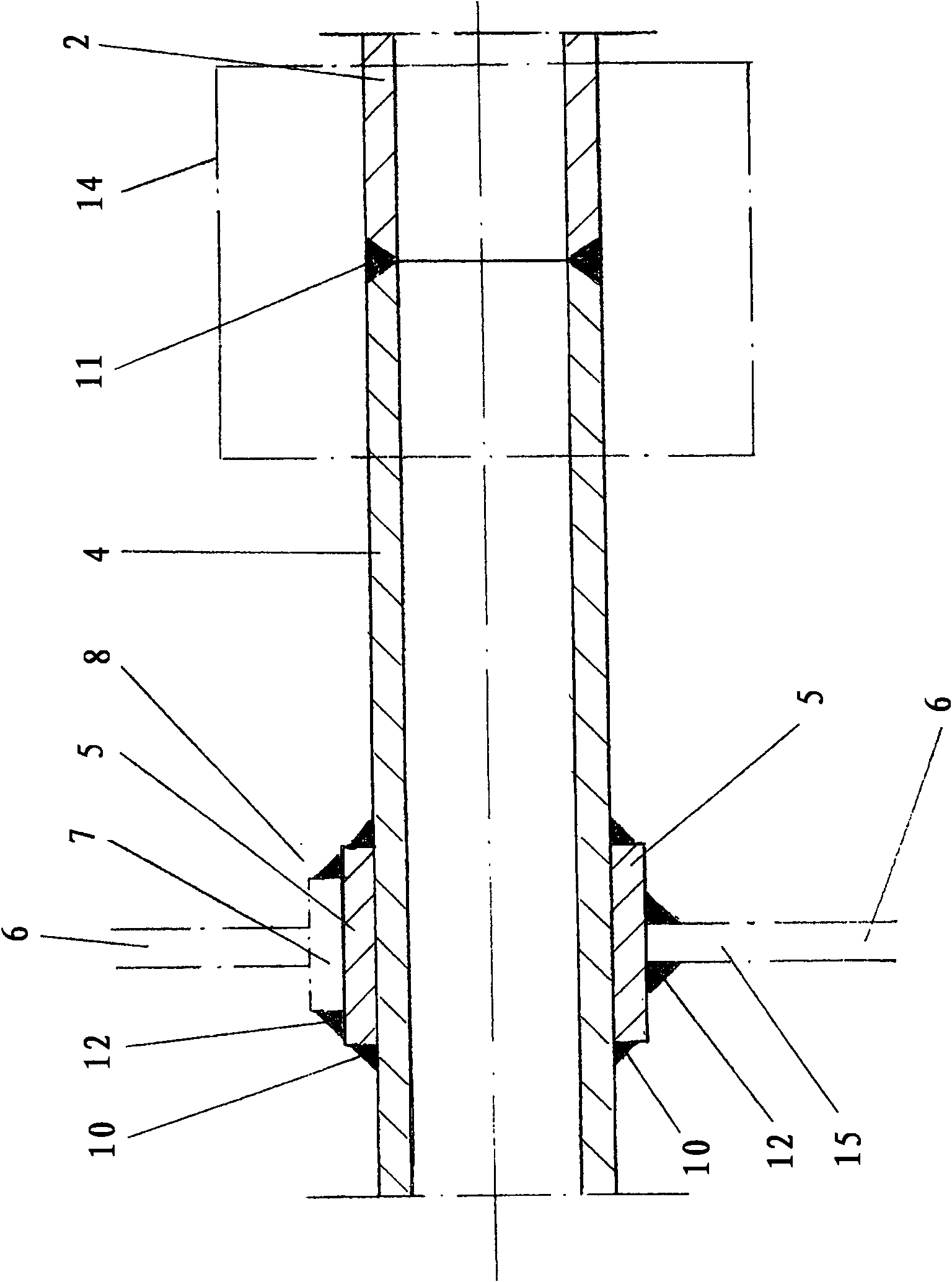

[0019] figure 1 By way of example, a superheater serpentine or superheater heating surface 1 is shown schematically produced and arranged and assembled inside a tube wall 6 of a steam generator (not shown), including the connection tube 4 passing through the tube wall 6 . For the sake of clarity, it is pointed out that inside the pipe wall 6 there are a plurality of figure 1 Superheater coils 1 shown in . The superheater coil 1 is produced in the workshop from a plurality of straight pipes 2 and bent parts 3 and is welded to the connection pipe 4 passing through the pipe wall 6 at the installation position, ie on the assembly side. The connecting pipe 4 itself is connected outside the pipe wall 6 to distribution and collection devices not shown, with which the working medium circulating in the steam generator—usually water, steam or a mixture of water and steam—can be fed to the superheated Coiled pipe 1 or derived from the superheater coiled pipe. The method for producing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com