Particulate separator, in particular particulate filter for separating particulates from an exhaust gas flow of a combustion engine

A technology of separator and exhaust flow, applied in the direction of internal combustion piston engines, exhaust devices, combustion engines, etc., can solve the problems of high heat storage capacity at temperature peaks, unfavorable and expensive active filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

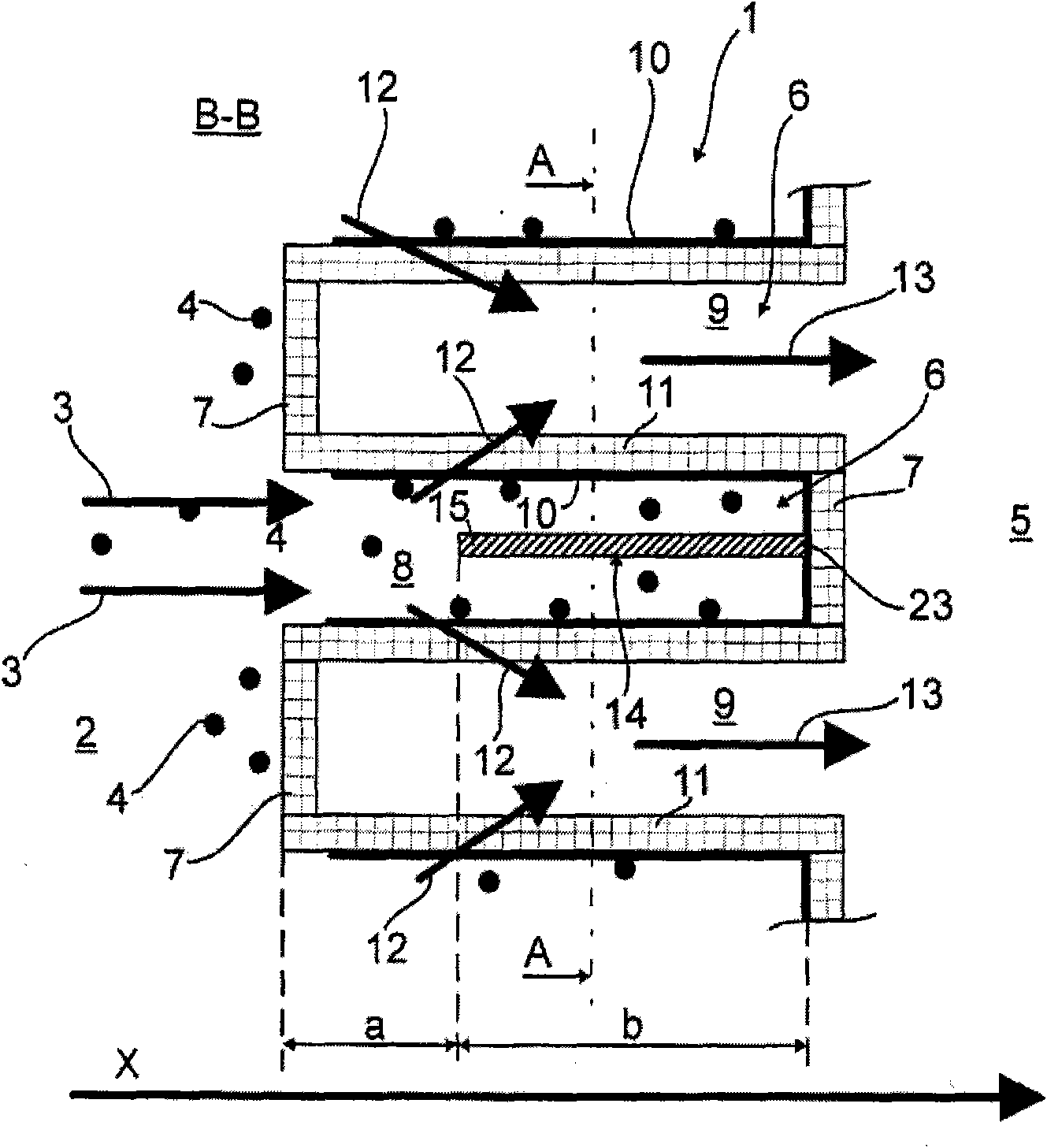

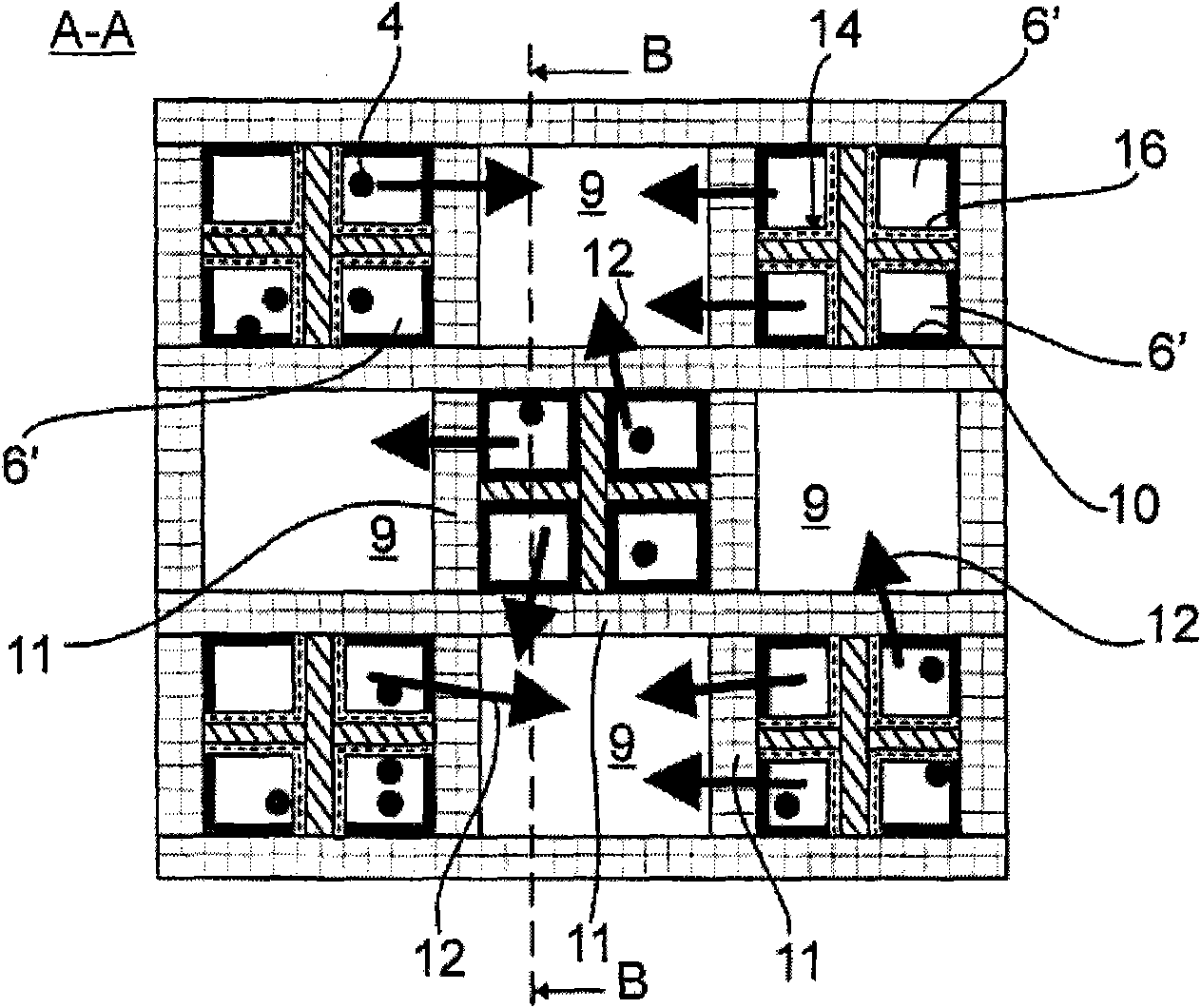

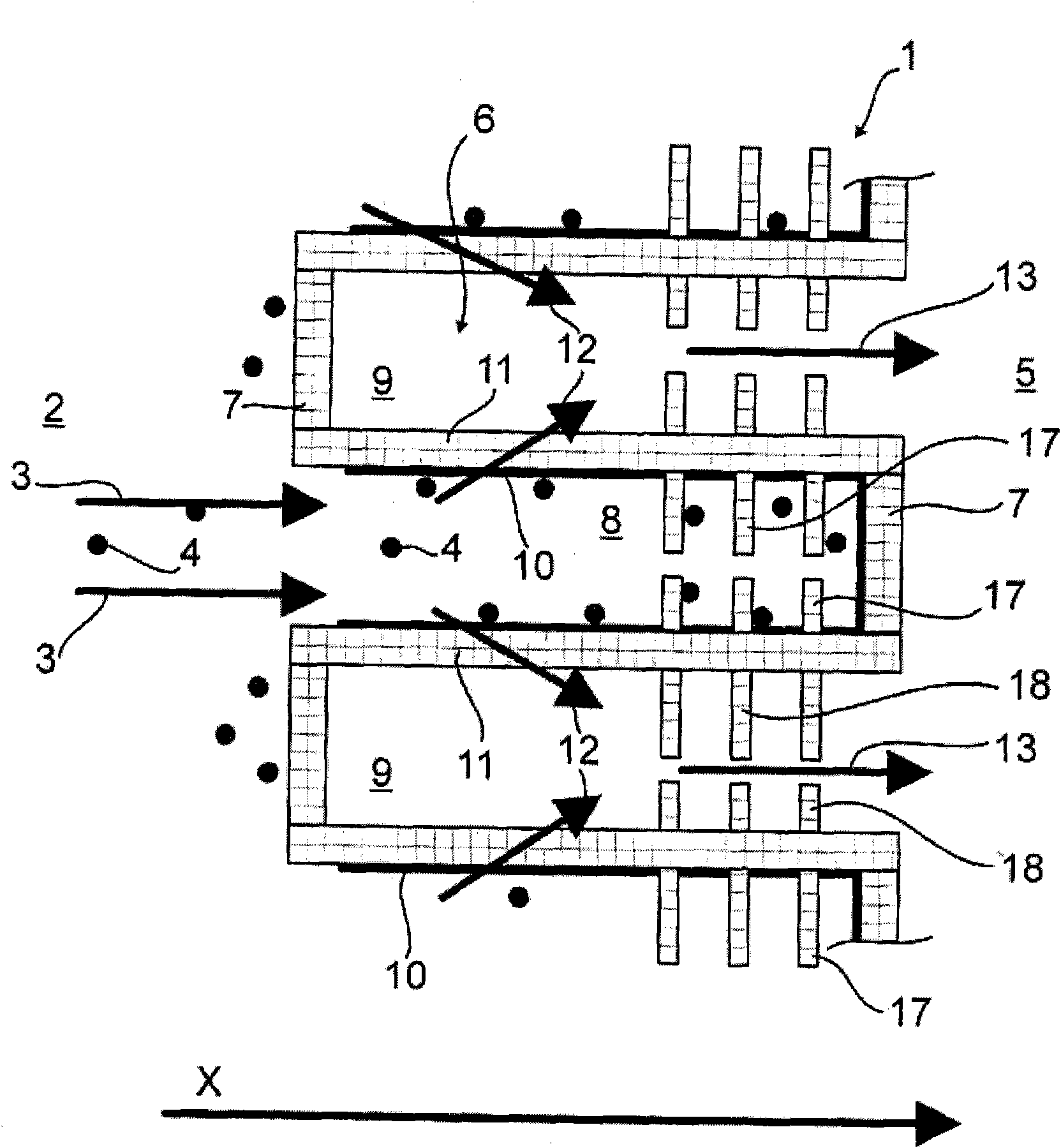

[0037] attached figure 1 Schematically shows a longitudinal section of the particulate filter 1 according to the invention, along the figure 2 The cross-section taken by section line B-B is shown. attached figure 2 shown along the attached figure 1 The cross-section taken by section line A-A is shown.

[0038] The untreated exhaust gas stream 3 entraining a large amount of soot particles 4 to be separated flows on the inflow side 2 to the particle filter 1 .

[0039] The particle filter 1 has several parallel flow channels 6 arranged directly next to each other, which channels are closed alternately, as shown, on the inflow side 2 and on the outflow side 5 opposite the main flow direction x with, for example, integrated end walls (Stirnwand) 7, The individual flow channels 6 alternately form a first blind or pocket chamber 8 open towards the inflow side 2 and a second blind or pocket chamber 9 open towards the outflow side 5 . Cordierite, aluminum titanate or silicon ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com