Heat radiating fan wheel

A technology of fan wheel and hub, applied in the field of cooling fan wheel, can solve the problem of single, high-frequency sharp noise and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

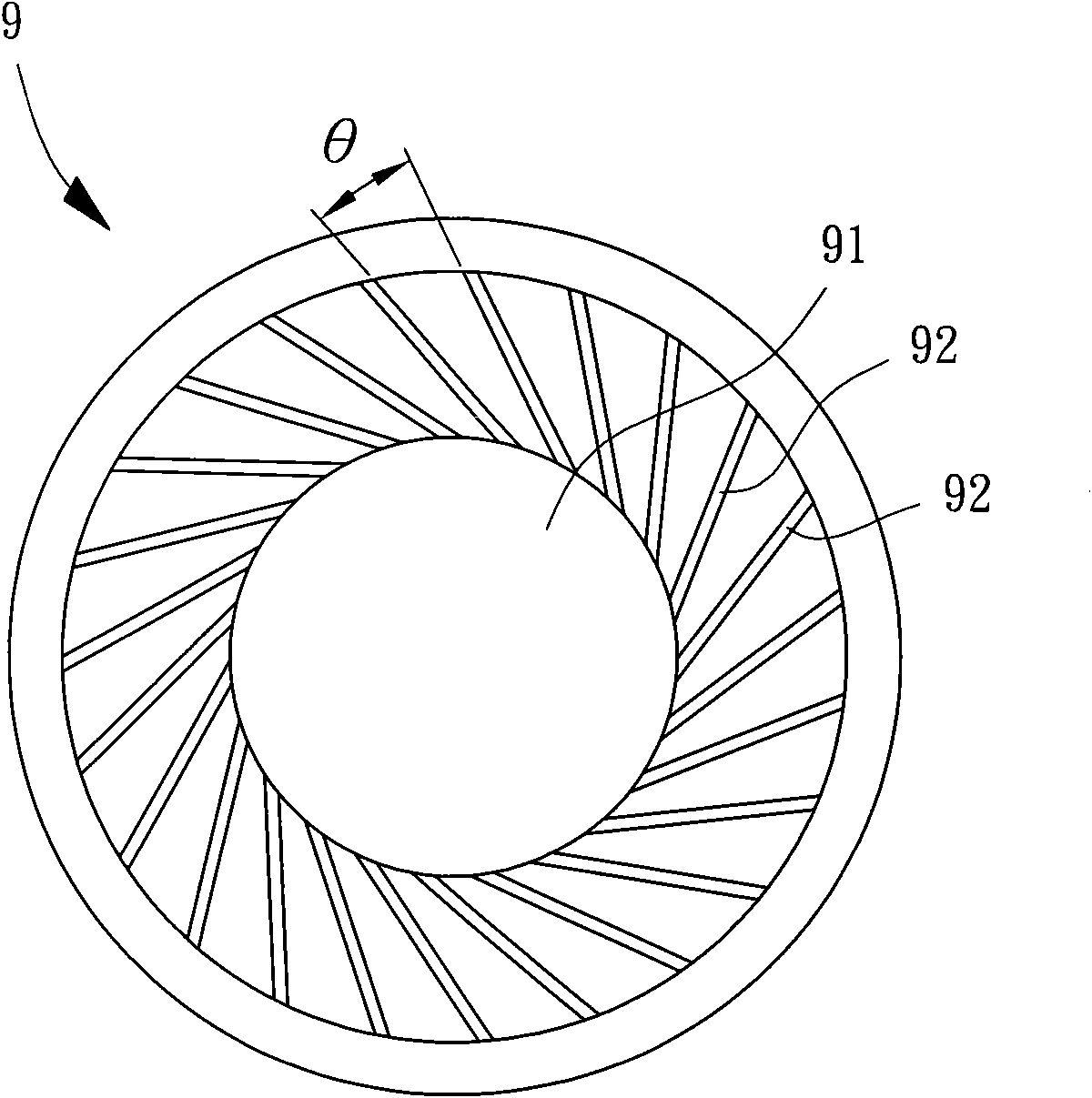

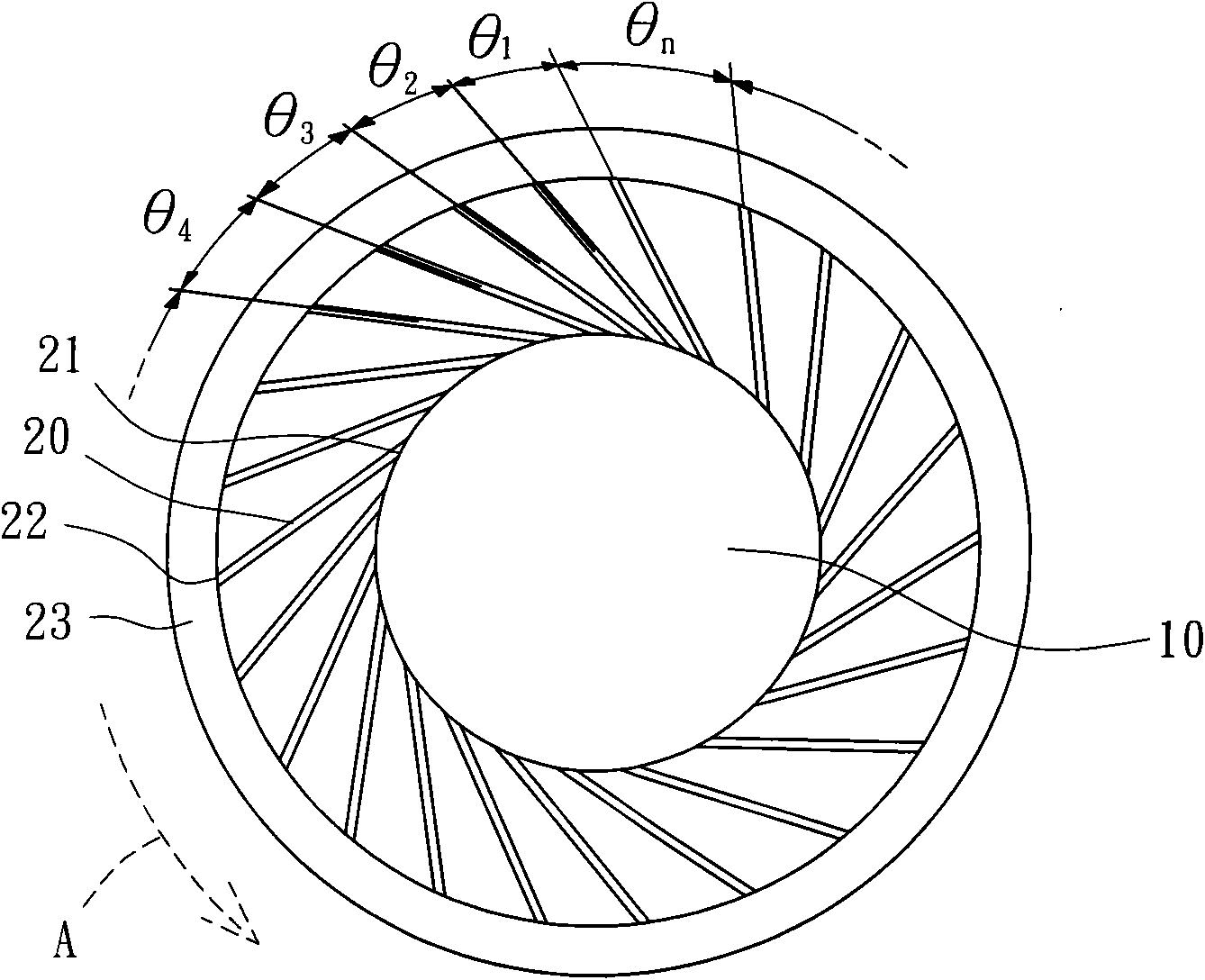

[0020] Please refer to image 3 As shown, the cooling fan wheel of the present invention has a hub 10 and several blades 20 . The hub 10 is mainly installed inside a blower fan frame (not shown), so as to drive the hub 10 to rotate by a stator; each of the blades 20 is radially connected to the outer peripheral surface of the hub 10 in a radial arrangement , and each of the blades 20 has different included angles, so that the included angles of each of the blades are sequentially designed to form incremental angles, thereby effectively reducing the intensity of single-frequency noise generated by the cooling fan wheel. Thereby, when the heat dissipation fan wheel of the present invention drives the external airf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com