Periodic waveguide array raster assembly

A periodic and waveguide technology, applied in the coupling of optical waveguides, etc., can solve the problems of complex overall structure, failure to meet user needs, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

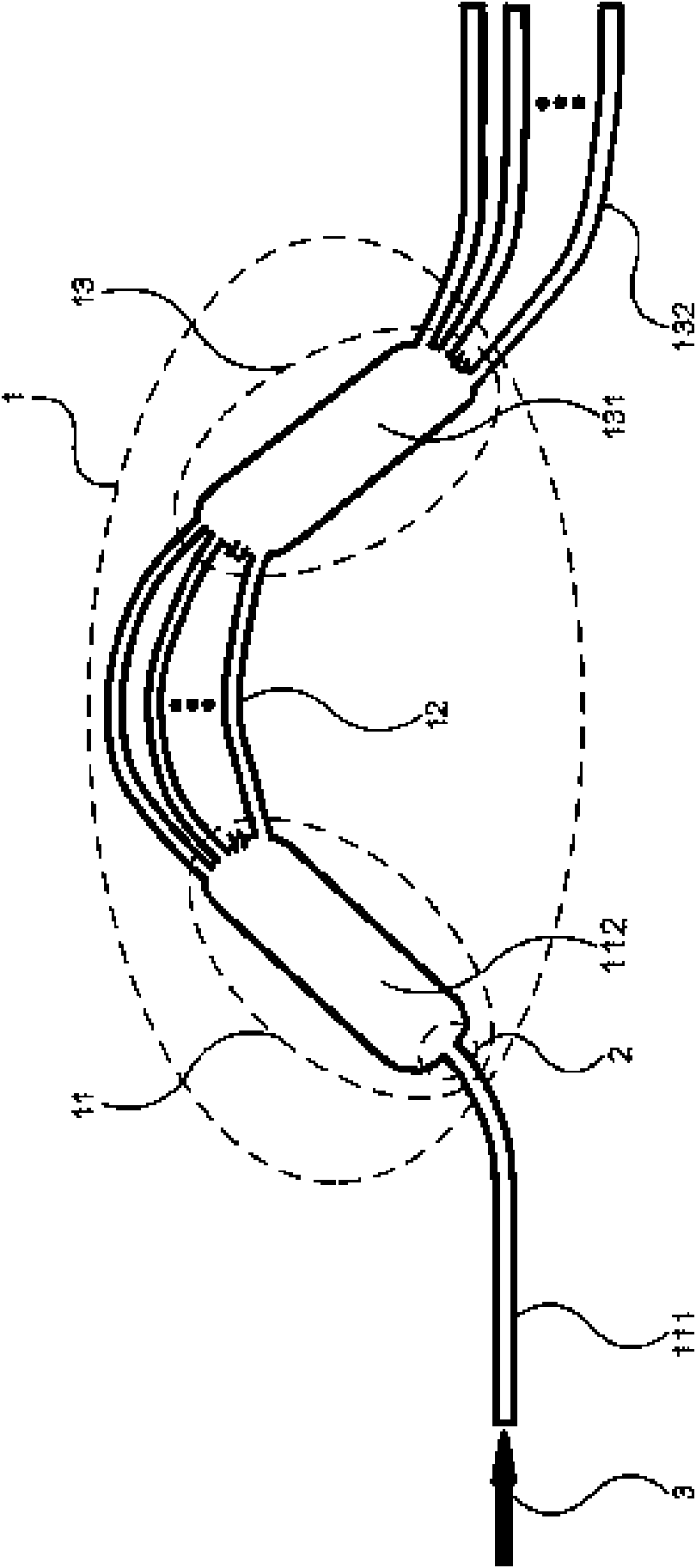

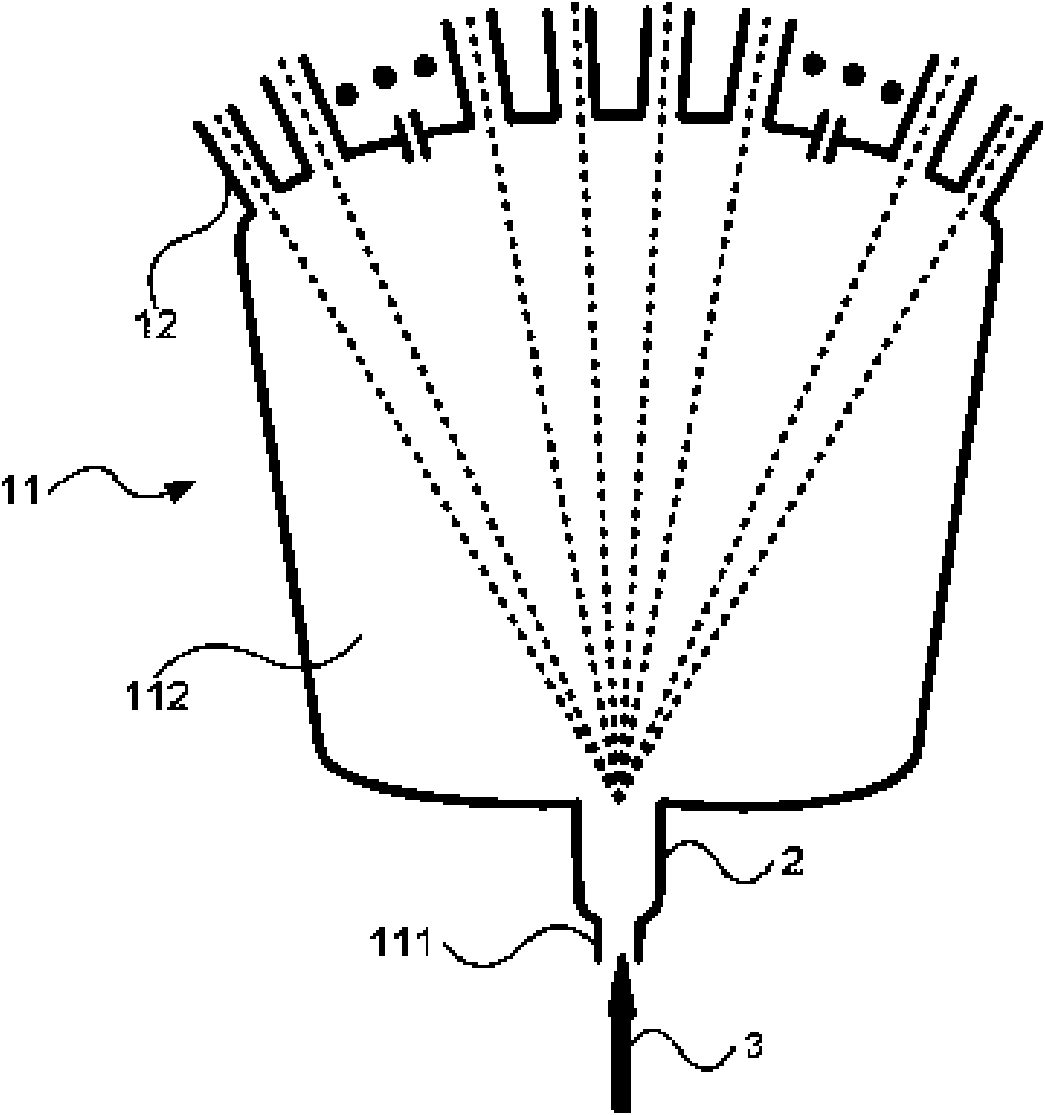

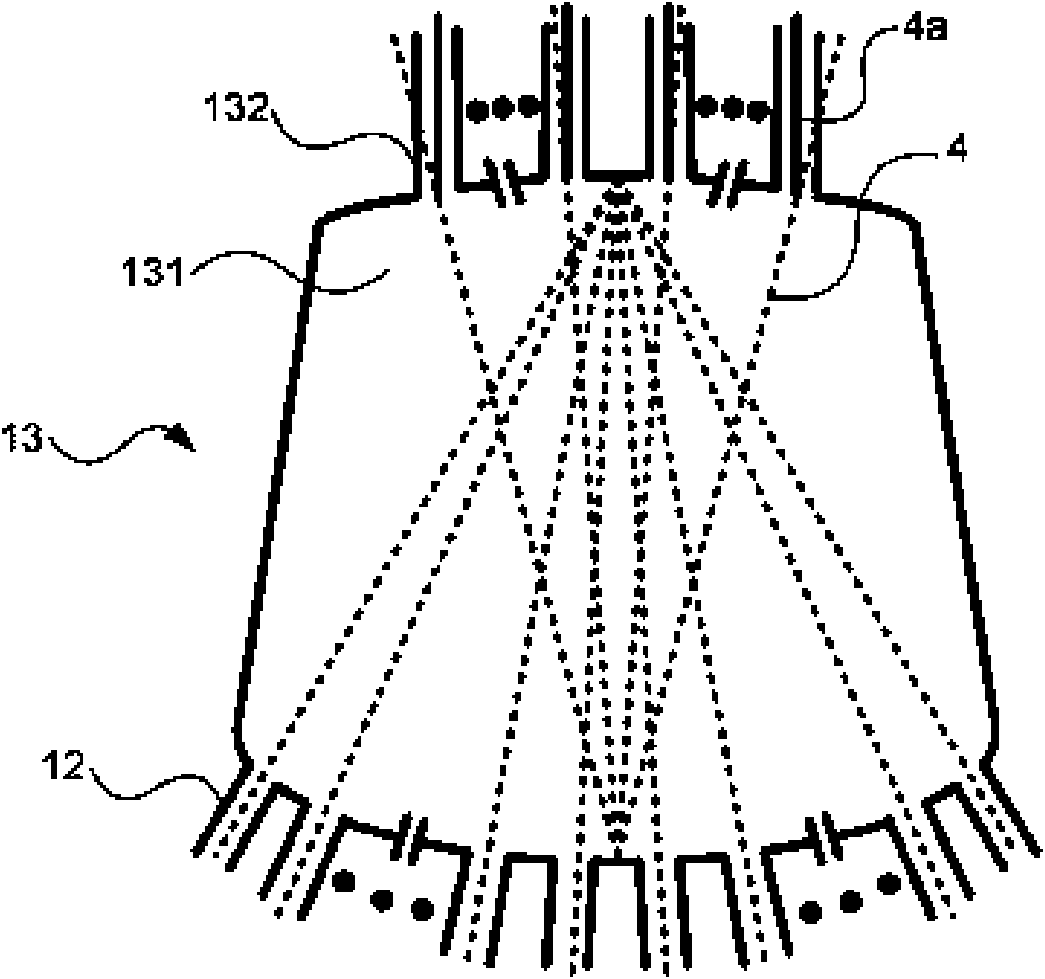

[0058] see figure 1 Shown is a schematic diagram of the periodic waveguide array grating assembly of the present invention. As shown in the figure: the present invention is a periodic waveguide array grating assembly 1, at least consisting of a first star coupler (star coupler) 11, a waveguide array 12, a second star coupler 13 and a horn-shaped waveguide 2, so that an optical signal 3 divided into multiple channels is deviated from the original central axis or a waveguide with an asymmetric structure is used, and the horn-shaped waveguide 2 is used to make the transmission frequency band (pass-band) of the optical signal 3 flat-top ( flat-top), used in various optical components.

[0059] The first star coupler 11 includes an input waveguide 111 and a first slab waveguide 112, so that the optical signal 3 is introduced through the input waveguide 111 and transmitted to the first slab waveguide 112, and the optical signal 3 is divided into several channels. ; The waveguide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com