Method for preparing electrodes of super capacitor based on nickel foam and products thereof

A supercapacitor and nickel foam technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor electrolytes, and hybrid/electric double layer capacitors, can solve problems such as affecting the performance of electrode materials, increasing costs, and complicating the preparation process, achieving high performance. Energy density, reduced raw material cost, excellent electrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Specifically, for the electrode preparation process of an asymmetric supercapacitor, the preparation method proposed by the present invention mainly includes the following steps:

[0045] First, the nickel foam is cleaned, and then soaked in an aqueous solution of graphene oxide with a mass concentration of 1 mg / ml to 10 mg / ml, thereby obtaining nickel foam deposited with graphene oxide;

[0046] Then, the nickel foam deposited with graphene oxide is used as the precursor material to make the positive and negative electrodes of the asymmetric supercapacitor respectively. The specific process is as follows:

[0047] The three-electrode method is used to perform constant voltage electrochemical reduction on the precursor material, wherein the nickel foam deposited with graphene oxide is used as the working electrode, the platinum electrode is used as the auxiliary electrode, and the saturated calomel electrode is used as the reference electrode, and the molar concentration...

Embodiment 1

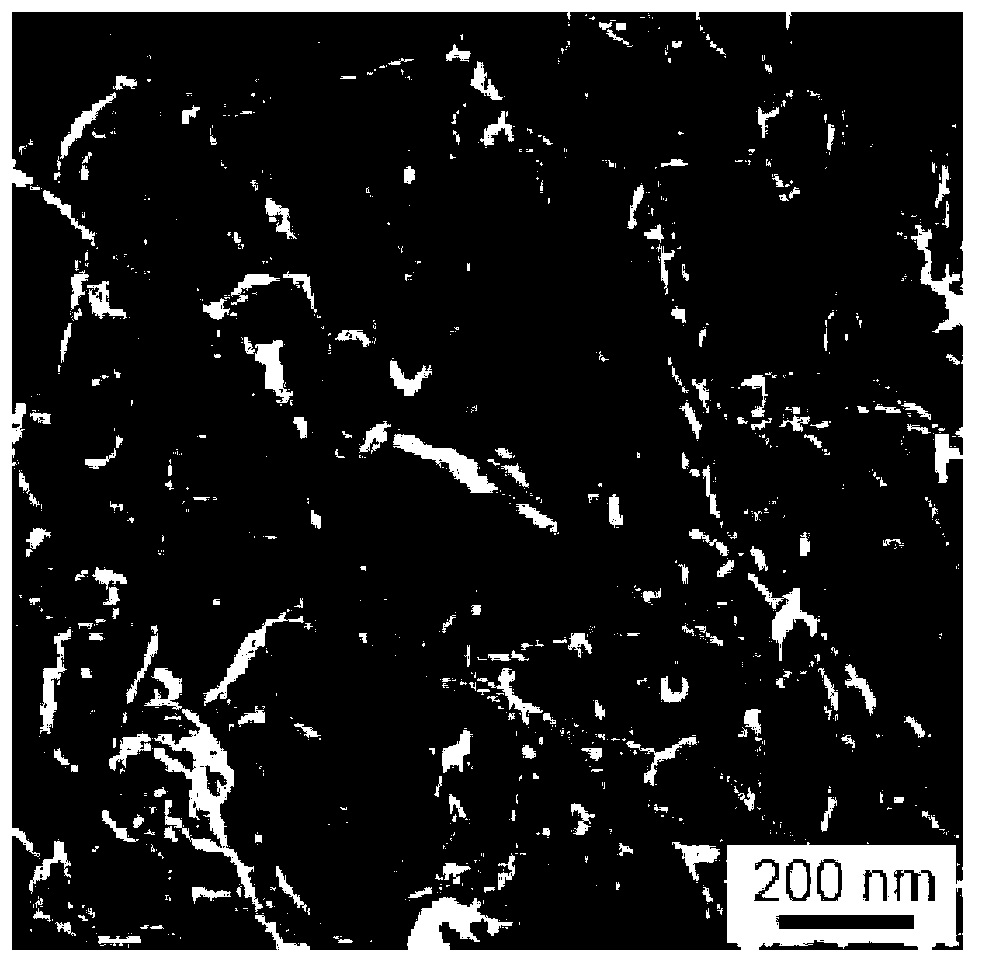

[0064] Cut the nickel foam into a suitable size and wash it with glacial acetic acid, acetone, ethanol and deionized water for 10 minutes. Then soak the cleaned nickel foam into a graphene oxide solution with a concentration of 5 mg / mL, and the temperature of the system is controlled at 80 degrees. After about 10 minutes, take out the nickel foam and dry it. The scanning electron microscope pictures can be found in the attached figure 1 .

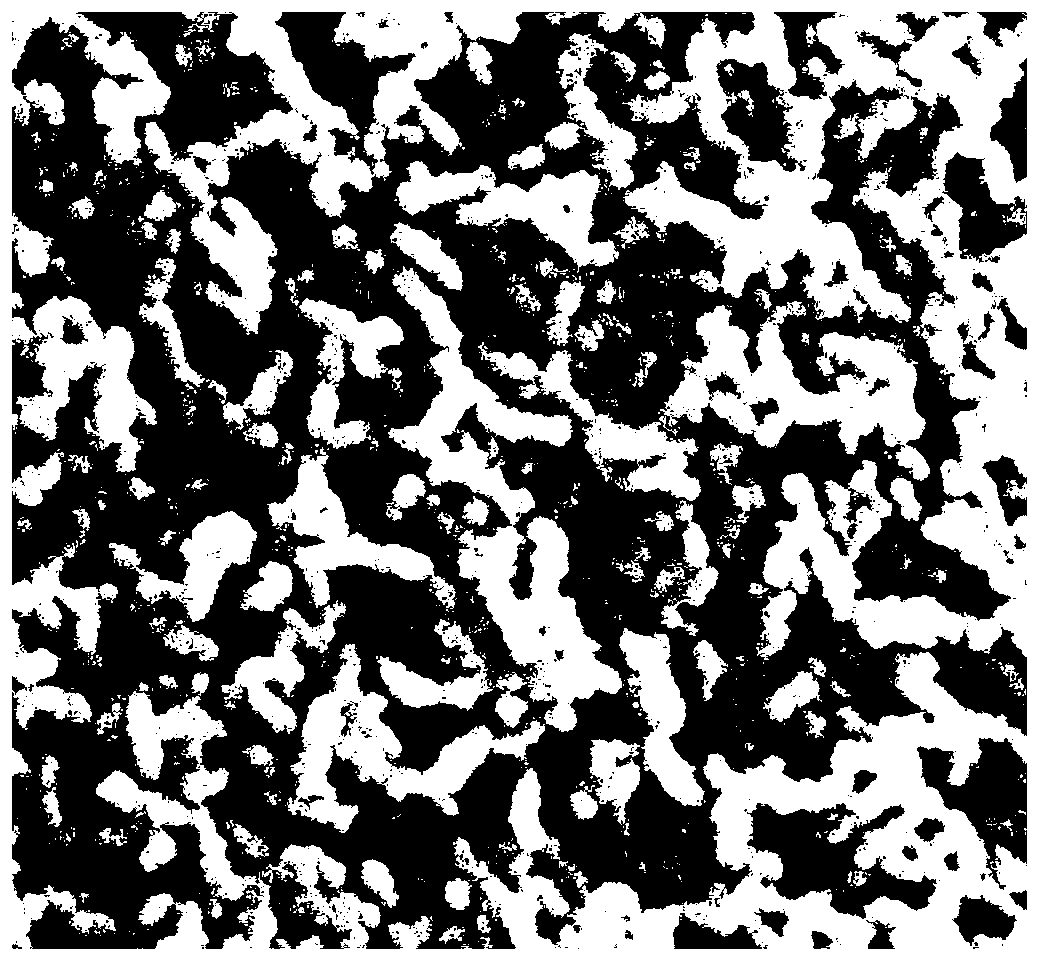

[0065] The nickel foam deposited with graphene oxide was subjected to constant voltage electrochemical reduction with a three-electrode method, the reduction potential was -1.5V, and the reduction time was 600s, and the nickel foam electrode deposited with graphene was obtained. In this process, the nickel foam deposited with graphene oxide was used as the working electrode, the platinum electrode was used as the counter electrode, the saturated calomel electrode was used as the reference electrode, and 0.5 mol / L sodium sulfate solution wa...

Embodiment 2

[0069]Cut the nickel foam into a suitable size and wash it with glacial acetic acid, acetone, ethanol and deionized water for 10 minutes. Then soak the cleaned nickel foam into a graphene oxide solution with a concentration of 1 mg / mL, and the temperature of the system is controlled at 40 degrees. After about 30 minutes, take out the nickel foam and dry it.

[0070] The nickel foam deposited with graphene oxide was subjected to constant voltage electrochemical reduction with a three-electrode method, the reduction potential was -1.0V, and the reduction time was 800s, and the nickel foam electrode deposited with graphene was prepared. In this process, the nickel foam deposited with graphene oxide was used as the working electrode, the platinum electrode was used as the counter electrode, the saturated calomel electrode was used as the reference electrode, and 1 mol / L sodium sulfate solution was used as the electrolyte. Next, soak the nickel foam deposited with graphene into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com