Lipid composition having excellent shape retention property and product

一种脂质组合物、保形性的技术,应用在含油脂食品配料、含天然提取物食品配料、非有效成分的医用配制品等方向,能够解决没有达到完全令人满意、无法充分满足热稳定性、操作繁琐等问题,达到优异热稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4

[0058] (Examples 1 to 4) Preparation of lipid composition

[0059] Weighed predetermined amounts of menthol and cholesterol to obtain the component ratios shown in Table 1, mixed them in a container, and then heat-treated them at 50°C to 100°C under normal pressure, thereby obtaining menthol and Cholesterol eutectic. Each lipid composition was prepared by solidifying the mixture at room temperature.

[0060] Table 1 shows the melting points of the lipid compositions of Examples 1 to 4. In this case, the melting point was measured using an automatic melting point apparatus (METTLER TOLEDO-FP900) within a temperature range of 30°C to 80°C (1°C / min).

[0061] [Table 1]

[0062] serial number

[0063] Example 4

Embodiment 5 to 12

[0078] (Examples 5 to 12) Preparation of Composition

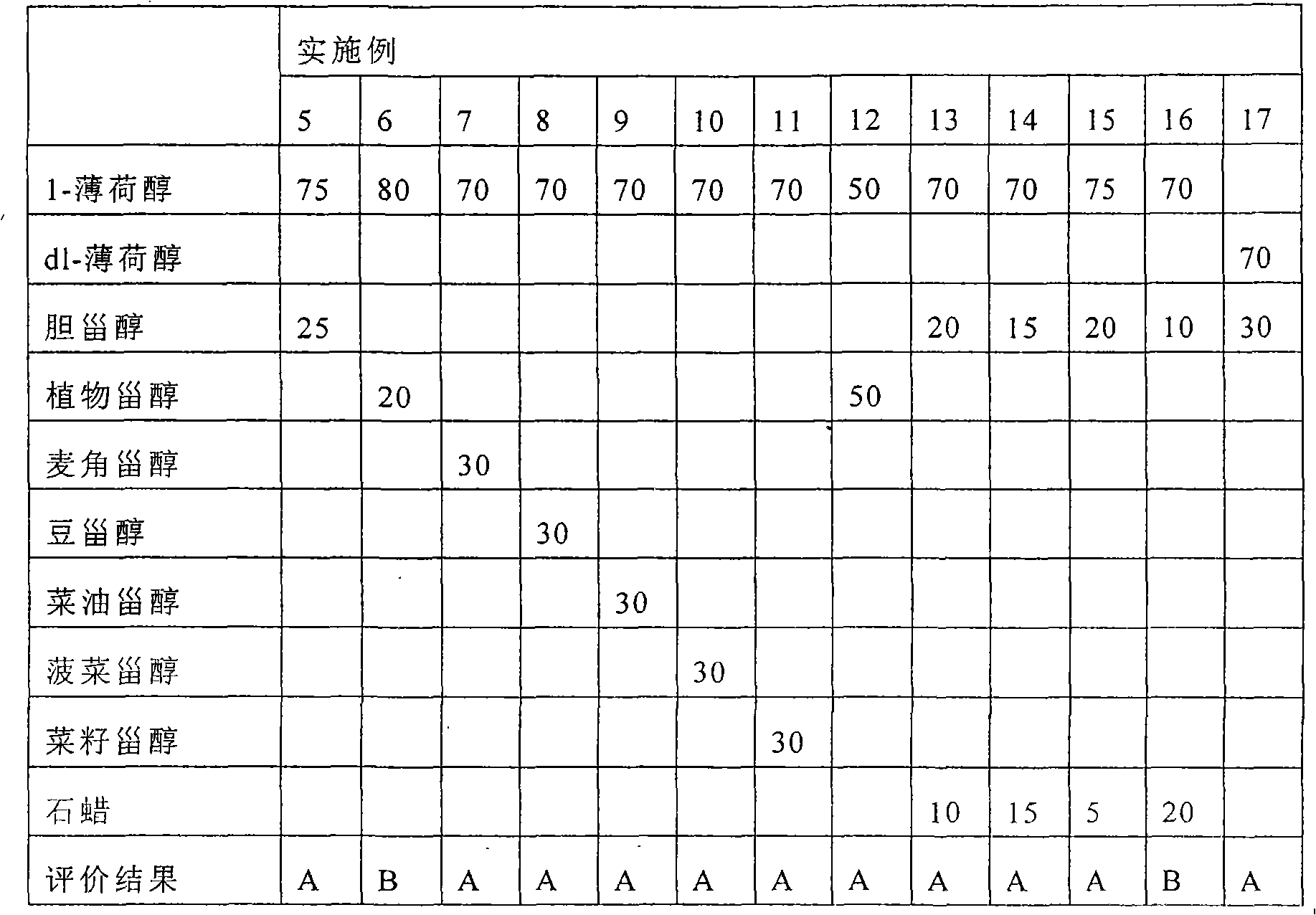

[0079] Take predetermined amounts of menthol and sterols described in Table 3 to obtain the component ratios shown in Table 3 to prepare lipid compositions, mix them in separate containers, and then 1 in the same manner. The lipid compositions of Examples 5 to 12 were treated in the same manner as Test Example 1, and their shape retention properties were determined respectively. The measurement results are shown in Table 3.

Embodiment 13 to 17

[0080] (Examples 13 to 17) Preparation of Composition

[0081] Weighed predetermined amounts of menthol and sterols and paraffin described in Table 3 to obtain the component ratios shown in Table 3 to prepare lipid compositions, mixed them in their respective containers, and then mixed them in accordance with the Carried out in the same manner as in Example 1. The lipid compositions of Examples 13 to 17 were treated in the same manner as Test Example 1, and their shape retention properties were determined respectively. The measurement results are shown in Table 3.

[0082] In Table 3, Ceresine 810 (manufactured by NIKKO RICA Co., Ltd.) was used as paraffin.

[0083] [table 3]

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com