Apparatus for producing feeds comprising dried and fermented animal and plant residues and dried and fermented fertilizers

A technology for drying fermentation, animals and plants, which is applied in the field of advanced equipment, which can solve the problems of small contact area, difficulty in evaporating outward, and difficult temperature management between the treated material and air, and achieve control of operating costs, low investment, and The effect of low mortality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Through the utilization of the fermentation energy of organic waste, the fermenter, screw conveyor, blower, conveying pipe, and finished product storage tank are cleverly combined to achieve efficient and economical drying.

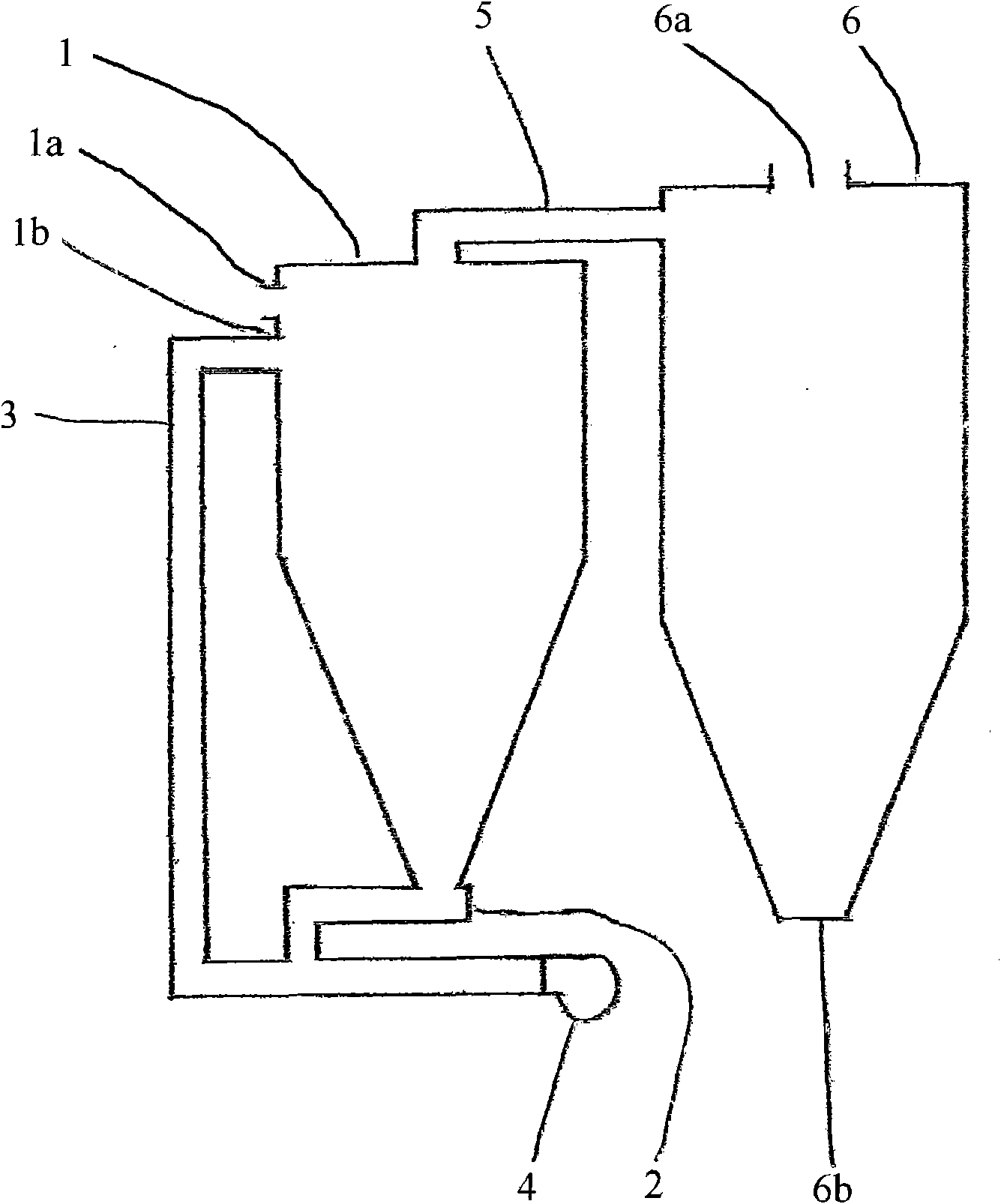

[0012] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. As shown in Fig. 1, the device for making dried fermented feed and dried fermented fertilizer by utilizing animal and plant residues according to the present invention includes a fermenter 1, a screw conveyor 2, a delivery pipe 3 for circulation, a blower 4, an exhaust With delivery pipe 5, finished product storage tank 6. Wherein, the top of fermentor 1 is provided with animal and plant residue input port 1a, circulation input port 1b, screw conveyor 2 and circulation delivery pipe 3, and circulation delivery pipe 3 is connected to screw conveyor 2 at the bottom of fermentation tank, The top of the fermenter is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com