Improved paint formulations comprising cellulose ether/network building polymer fluid gel thickeners

一种纤维素醚、网状结构的技术,应用在触变涂料、涂层、乳胶漆等方向,能够解决损失其它特性、增加成本、脱水收缩和悬浮性不好等问题,达到改善雾化性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation of Viscous Fluid Gels

[0056] Thickening system fluid gels are prepared according to three different methods, as follows:

[0057] Method A, hot mix (with low acyl gellan gum or high acyl gellan gum)

[0058] Finnfix 2000: KELCOGEL CG-LA or FINNFIX 2000: KELCOGELLT 100 - HA powder was dried at room temperature (-25°C) with mixing - stirring and adding to deionize the water. With mixing, the contents were heated to 90°C for 5 minutes. For mixtures, without mixing, add 5 mM Ca++ (e.g., CaCl2) or 1% NaCl, then cool to ~25°C, at which point, resume moderate mixing to form a weak gel, biocide Adding and fluid gels are placed in containers to be added to the paint at any point in the manufacturing process (for example, following pigment dispersion or after latex binder addition).

[0059] Method B, cold mix (in situ) at the beginning of grinding the pigment (using low acyl gellan gum):

[0060] For the standard paint treatment, the container was filled wi...

example 1

[0066] Paints were prepared according to Preparation B to estimate the suspension of pigment in acrylic semi-gloss latex paint (25% PVC) at a pH of about 8.3. A comparison was made between a single gum CMC containing system and a system stabilized with a mixture of cellulose gum and LA-gellan gum. The paint was mixed with the appropriate amount of thickener to achieve a Stormer tack of 77+ / - 1KU of the paint.

[0067] water

[0068] About the dispersion of high-speed disperser

example 2

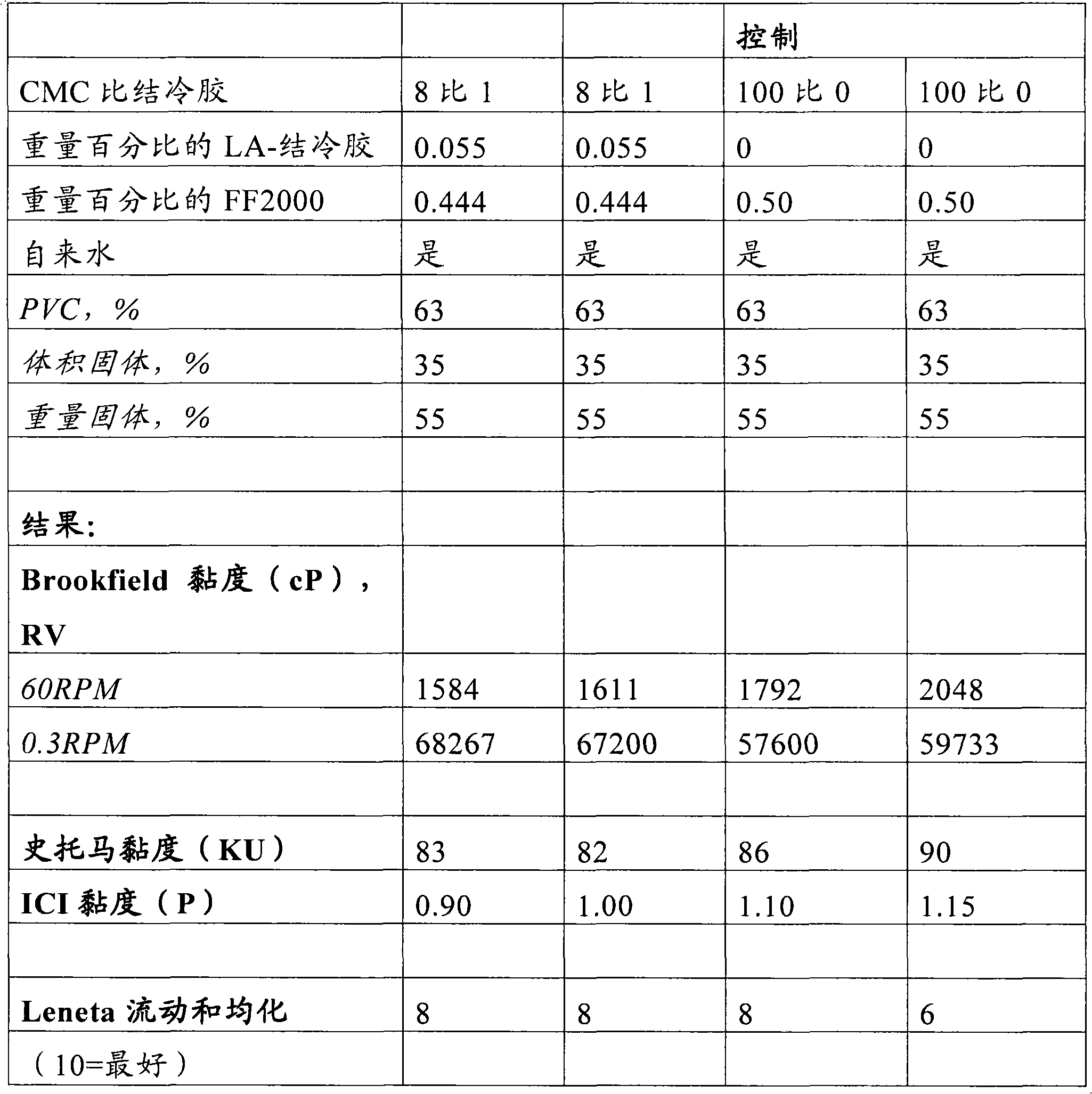

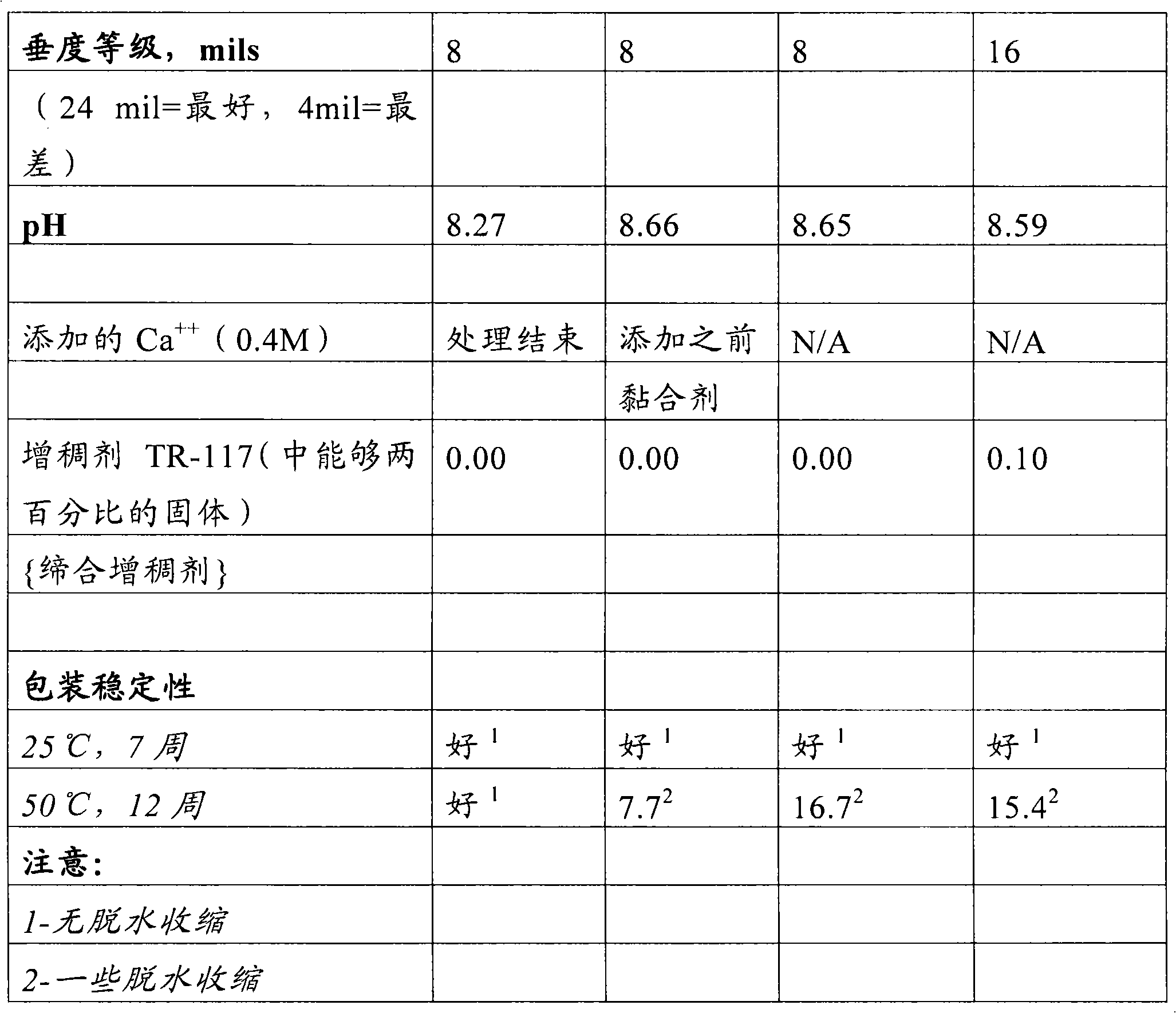

[0070] Paints were prepared according to Preparation B to estimate a suspension of pigment in a matte latex paint (63% PVC) at about 8.5 pH. A comparison was made between a single gum CMC containing system and a system stabilized with a mixture of cellulose gum and LA-gellan gum. Additionally, comparisons have been made to references that also included associative thickeners. For systems including gellan gum, salt was added as a gelling agent, and the time of addition was varied for comparison. Paints were prepared with 0.5% by weight thickener.

[0071] components

[0072] Ethylene Propylene Glossy Emulsion

[0073] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com