Method and apparatus for cleaning metal plate and spray nozzle for cleaning metal plate

A technology for spraying nozzles and cleaning devices, which is applied in cleaning methods and appliances, cleaning methods using liquids, spraying devices, etc., and can solve problems such as inability to obtain printing quality and clogging of metal plate meshes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

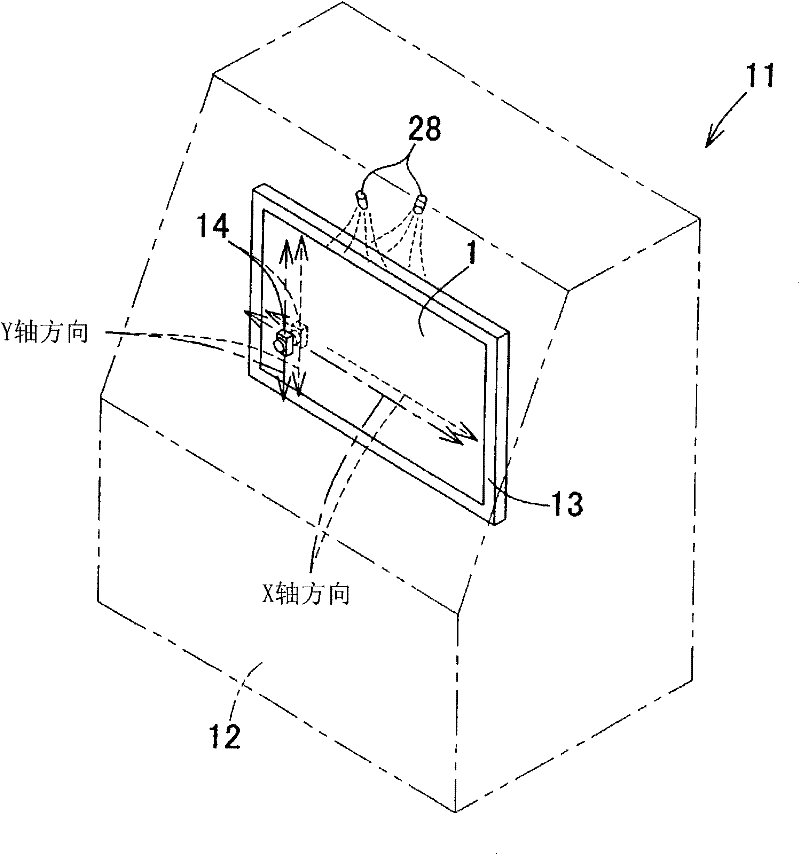

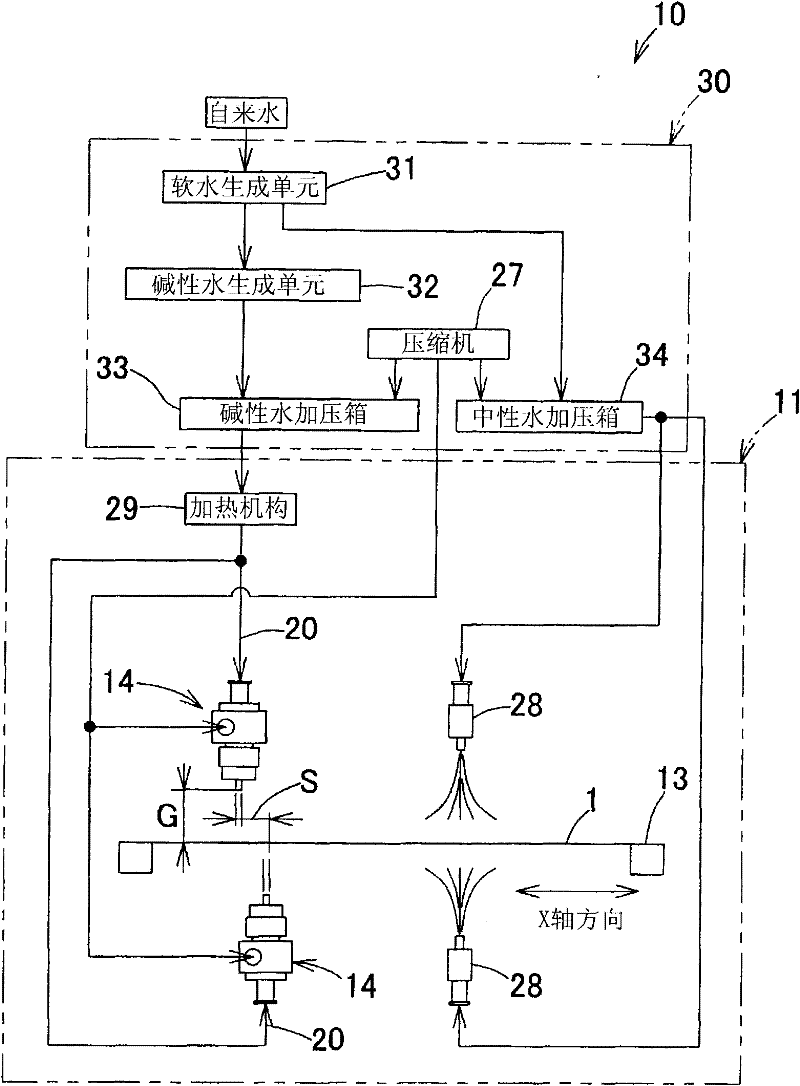

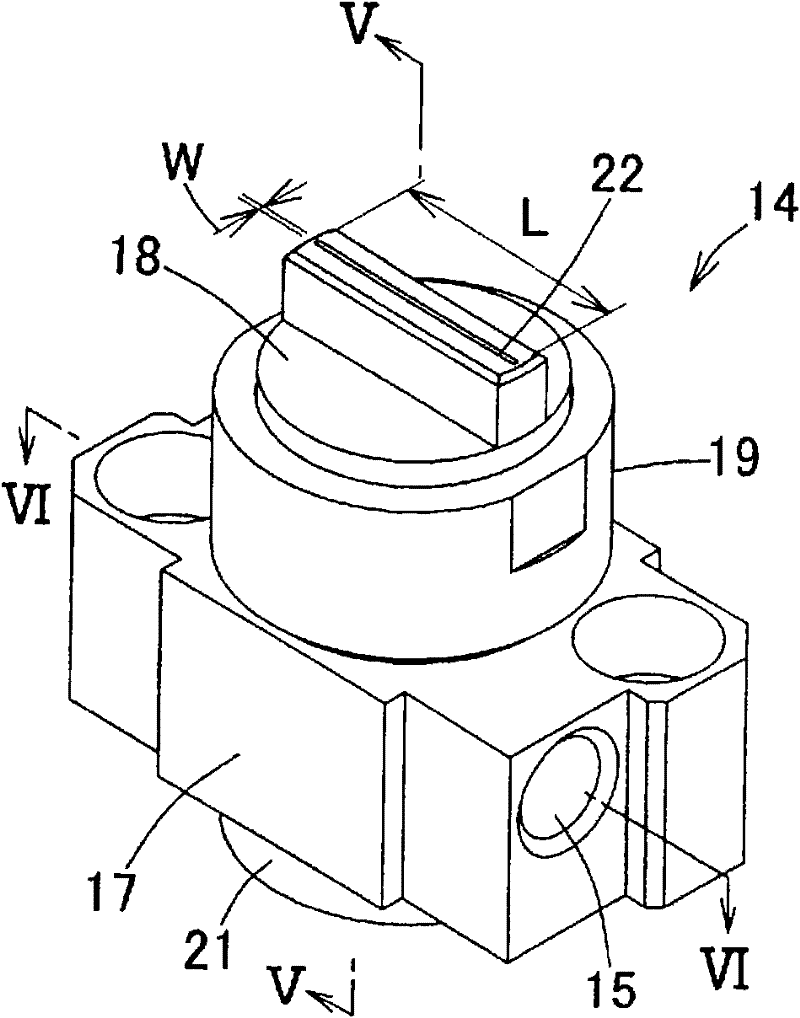

[0058] Such as figure 1 , figure 2 As shown, the metal plate cleaning device 10 includes: a cleaning device body 11 that sprays finely granulated alkaline water onto the metal plate 1 to clean the metal plate 1; and an alkaline water supply that supplies alkaline water. device 30.

[0059] A frame-shaped reinforcing frame 13 is integrally provided on the outer periphery of the metal plate 1, and the metal plate 1 is supported at a certain angle relative to the horizontal direction in the housing 12 of the cleaning device body 11, and sprayed on the metal plate 1. Alkaline water flows down the metal plate 1 . The inclination angle of the metal plate 1 relative to the horizontal direction can be set arbitrarily, but, in order to make the cleaning device body 11 miniaturized as much as possible, as figure 1 , Figure 12 As shown, it is preferably set at 90° with resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com