Receiving device for determining foreign parts

A sensor device, foreign object technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as measurement results errors, achieve simple and reliable installation, prevent insulation from being damaged, stray current and its electromagnetic interference field Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

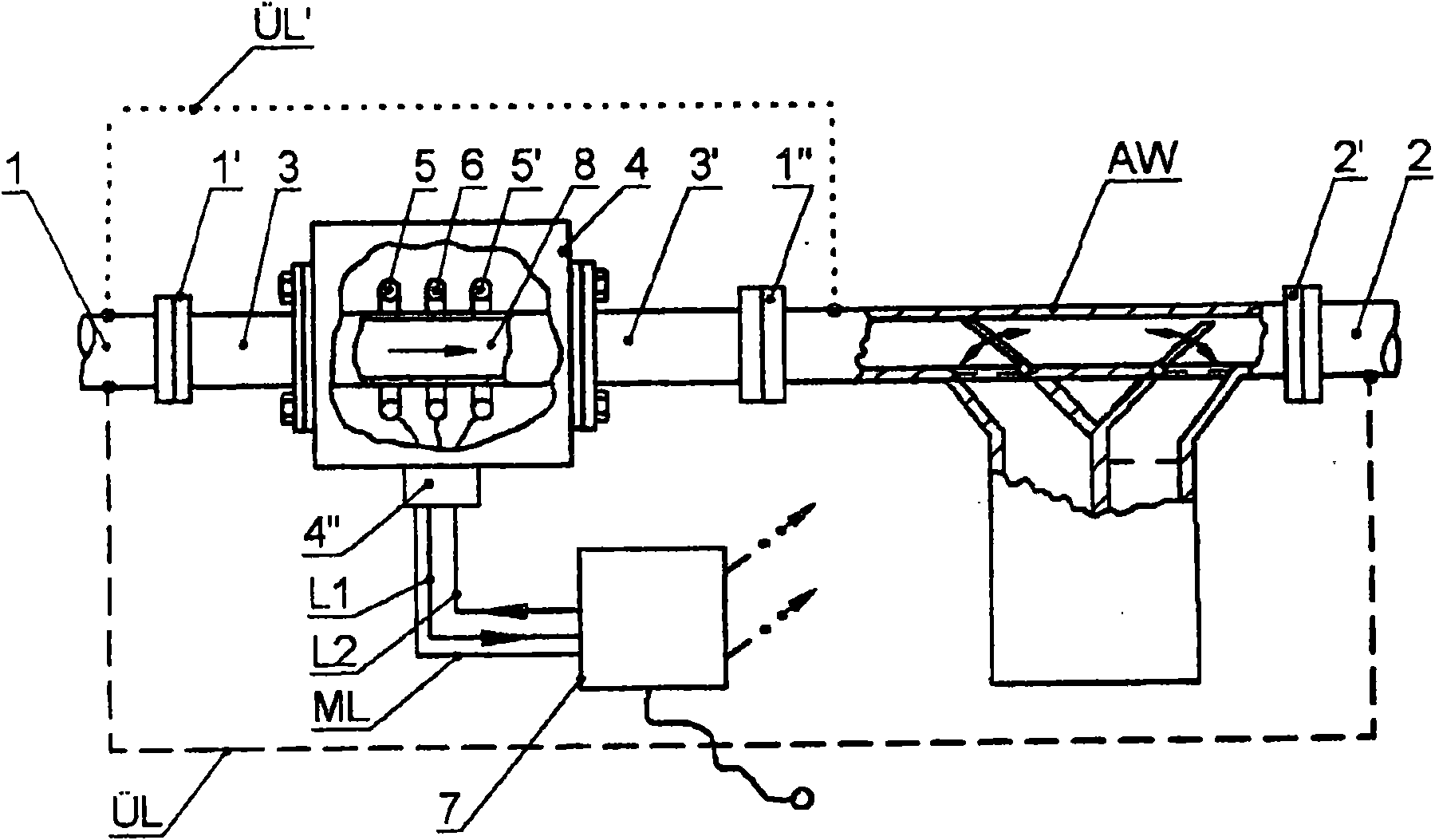

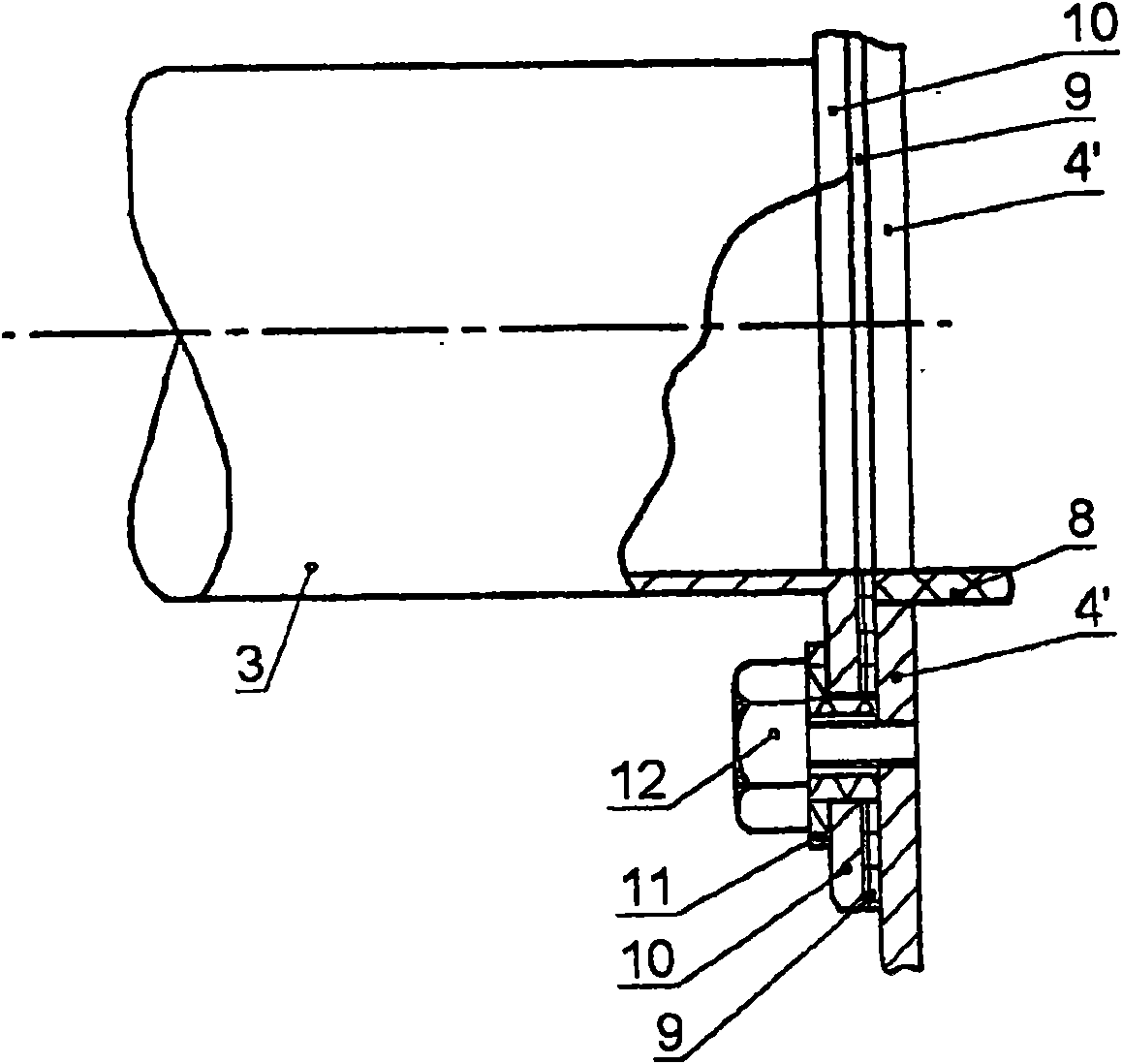

[0009] exist figure 1 A device of the type in question rearranged according to the invention is schematically shown in . The device is a monitoring and separation section of a pneumatic tube conveying system for, for example, granular or fibrous conveying material, wherein the conveying material enters the device via the conveying pipe or conveying pipe 1 according to the suction or pressure method (Druckverfahren) , through the equipment and exit via the metal transfer pipe or delivery pipe 2. A pipe flange connection 1 ′ is connected to the delivery pipe 1 , which pipe flange connection is detachably connected to another metal pipe flange 3 . The pipe flange 3 has a planar flat contact surface at its end remote from the flange connection 1 ′. Such as figure 2 As shown in the lower area with respect to the pipe flange 3, the pipe flange is firmly fixed to the adjacent metal end plate of the shielding shell by a threaded connection, and a thin insulating layer 9 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com