Articulated robot for laser ultrasonic inspection

An ultrasonic and robotic technology, applied in the direction of material analysis, instruments, and manipulators using sonic/ultrasonic/infrasonic waves, which can solve problems such as increasing the initial total cost of laser ultrasonic testing systems, maintenance costs, inability to test the assembly structure, and discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

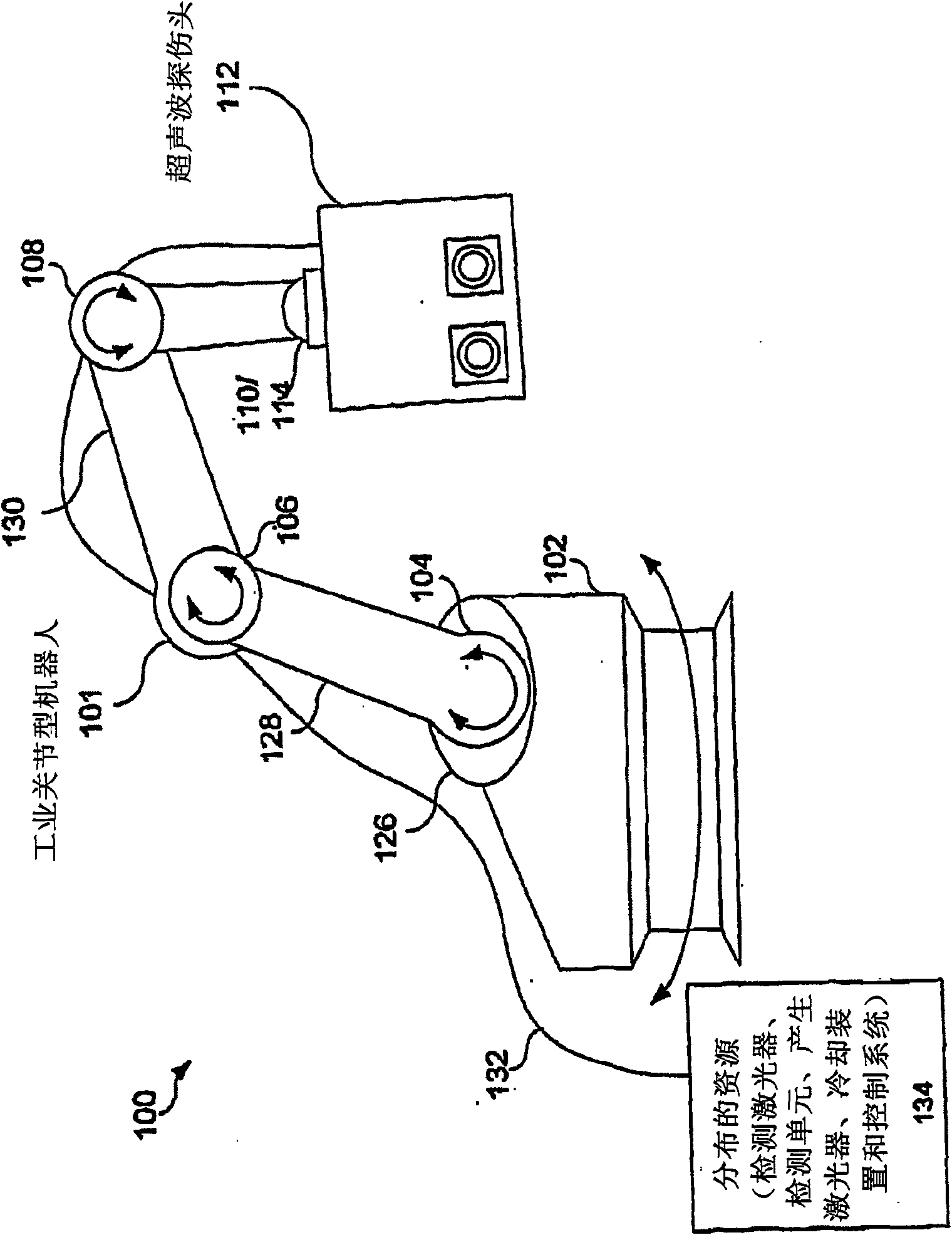

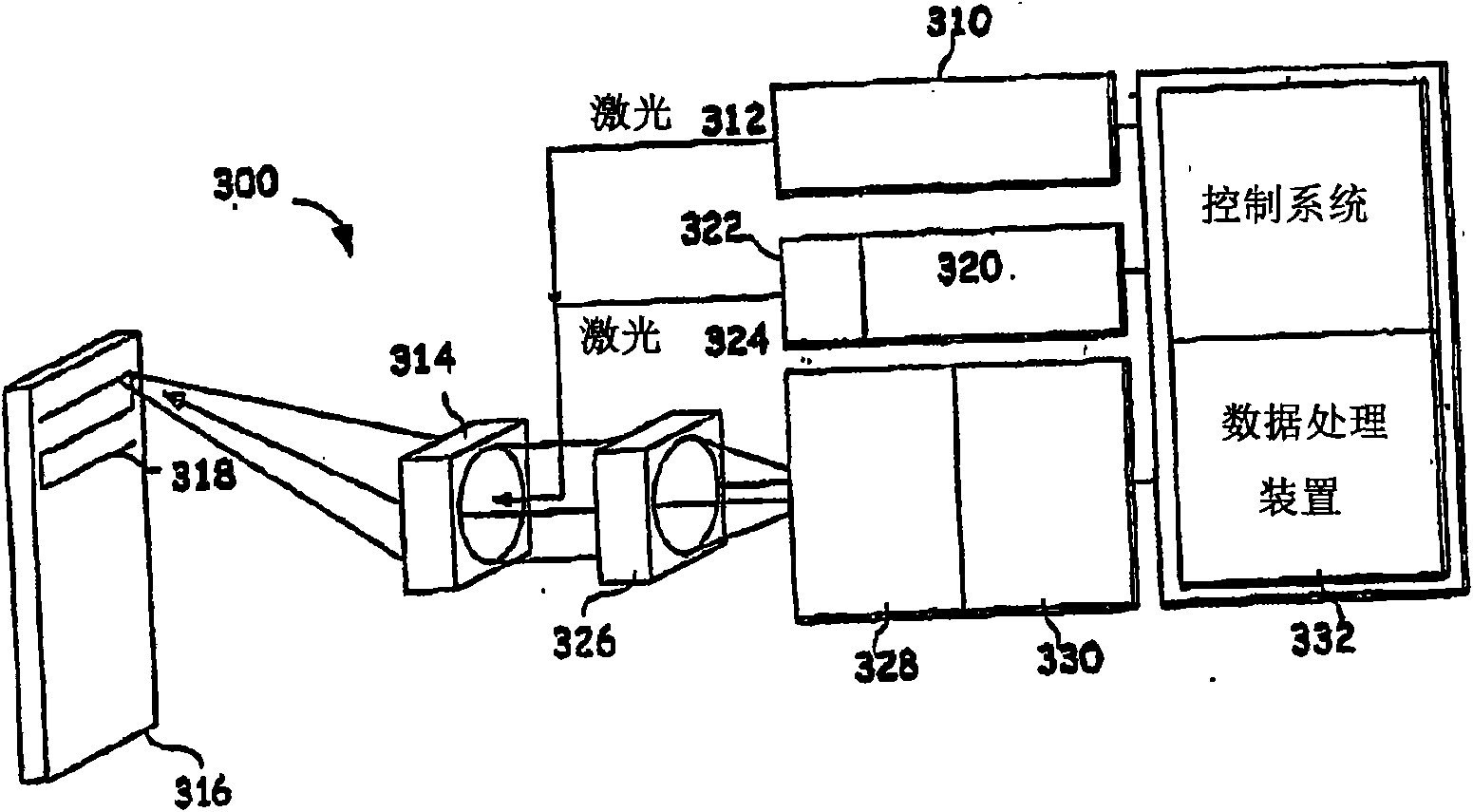

[0031] Preferred embodiments of the invention are depicted in the drawings, like numerals being used to designate like and corresponding parts in the different drawings.

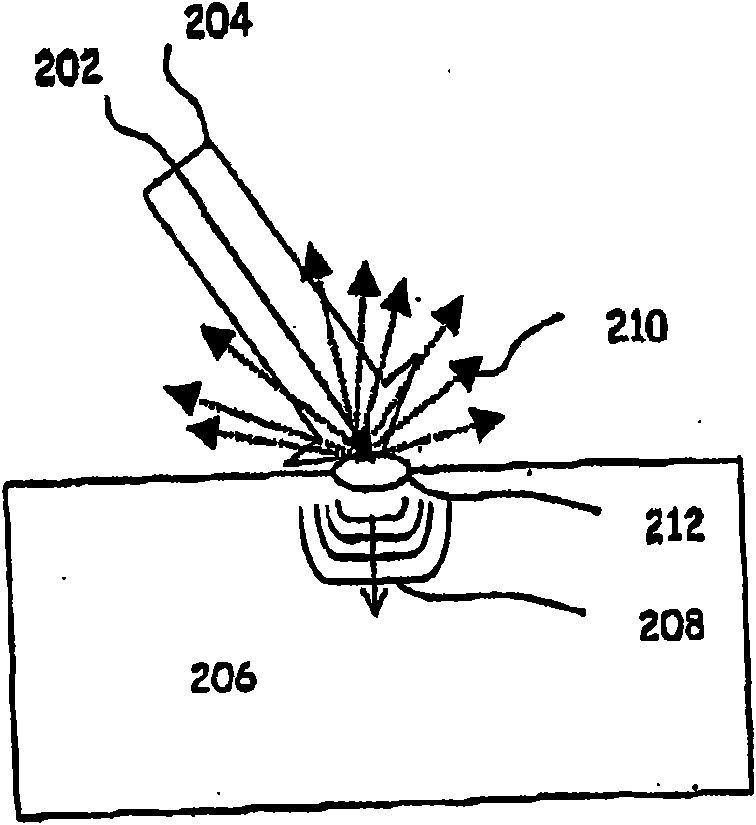

[0032] Laser ultrasonic flaw detection has proven to be a cost-effective tool for non-destructive evaluation (NDE) of polymer-matrix composites. With the increasing use of these composite materials in different industries, the number and complexity of composite parts is increasing. In addition, the installed base of composites is increasing. As objects made of composite materials increase in size and complexity, it becomes increasingly difficult to position laser ultrasonic sensors relative to the surface being inspected. Embodiments of the invention disclosed herein propose a solution to this problem.

[0033] One embodiment places a laser ultrasonic sensor (ie, a laser ultrasonic head) at the end of an articulated robot. Laser ultrasonic flaw detection is typically performed by moving the laser ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com