Molecular sieve compressing device of pressure swing adsorption air separation unit adsorption tower

A technology of air separation equipment and pressure swing adsorption, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increased equipment manufacturing costs, increased energy consumption, and bulky compaction devices, and achieves a compact appearance , low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

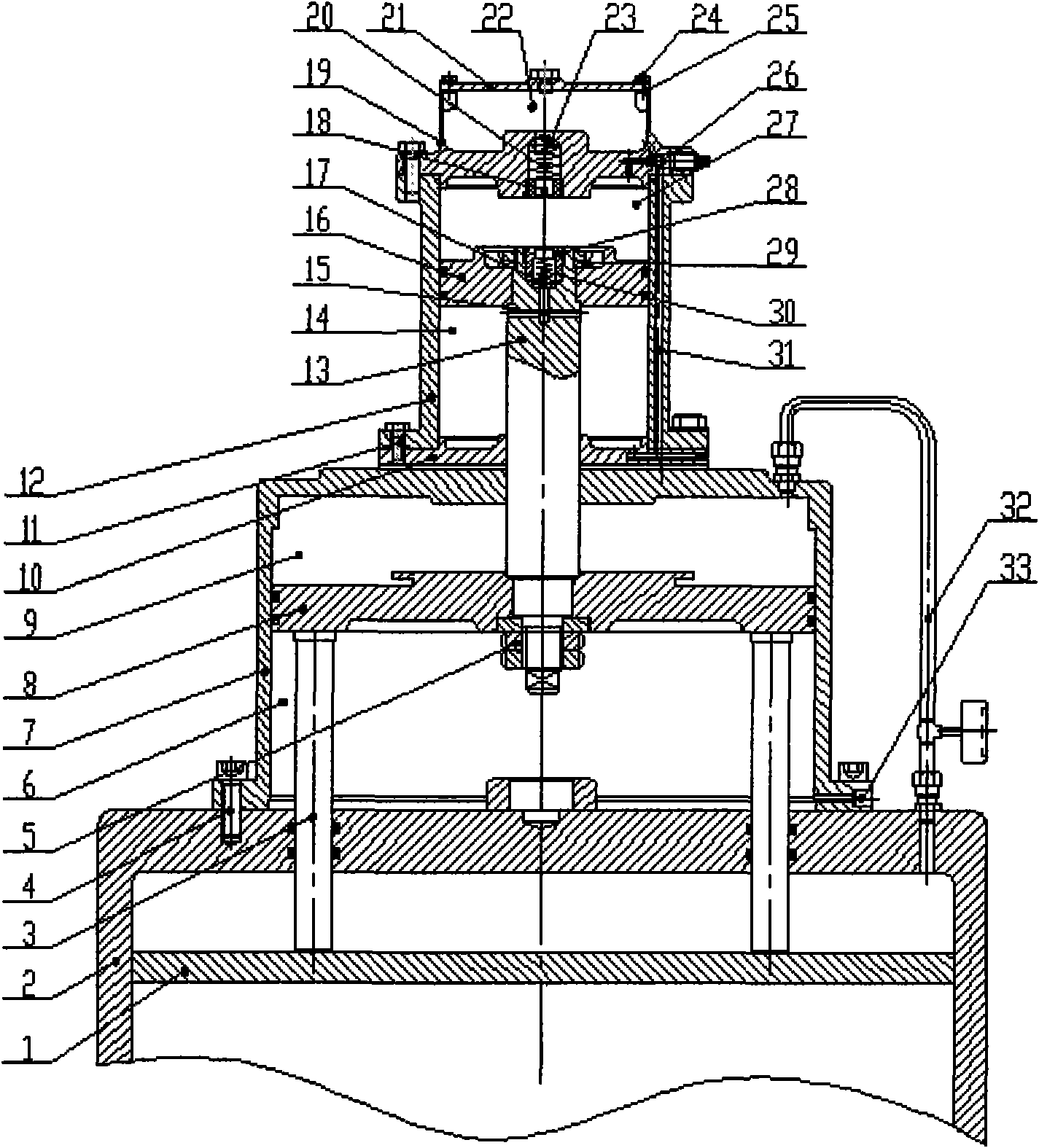

[0011] Depend on figure 1 It can be seen that the present invention includes: a cylinder 7 fixed on the top of the adsorption tower 2; also includes: a hydraulic cylinder arranged on the cylinder 7; the piston shaft of the cylinder and the piston shaft of the hydraulic cylinder are the same shaft;

[0012] The cylinder 7 is fixed on the top of the adsorption tower 2 by the first bolt 4, the lower end of the ejector rod 3 in the cylinder is in movable contact with the molecular sieve pressure plate 1 in the adsorption tower, and the upper end is in movable contact with the cylinder piston 8; the upper chamber 9 of the cylinder is in contact with the adsorption tower. There is an opening and closing air passage 32 between the towers 2, and the lower cavity 6 of the cylinder communicates with the atmosphere through the hole 33;

[0013] Be provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com