Rolling-over hanger

A spreader and hanger technology, which is applied in the field of industrial large-part overturning devices in the air, can solve problems such as complicated installation and disassembly, inconvenient operation, and complicated structure, so as to improve labor efficiency, facilitate storage and transportation, and be simple to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

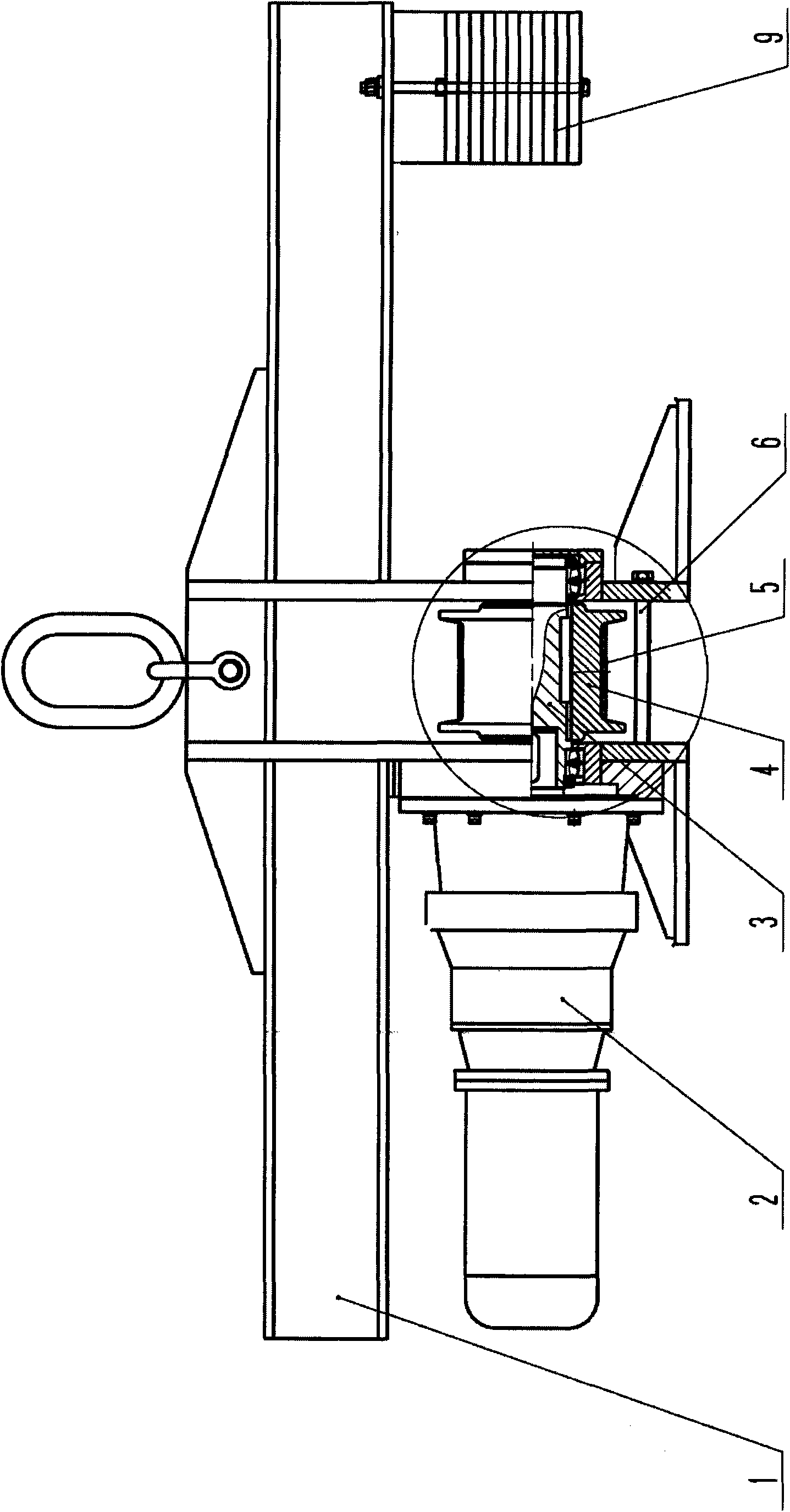

[0017] figure 1 What is shown is the schematic diagram of the structure of the turning sling when the number of reducers is 1, and the sling is not shown in this figure. figure 1 The turning spreader shown is composed of a hanger 1, a reducer 2, a shaft 3, a reel 4, a rubber 5, a limit rod 6, a counterweight 9, etc., wherein the reducer 2 is fixed on the hanger 1, and the reel 4 is connected with the reducer 3 through the shaft 3, the limit rod 6 is installed on the hanger 1, the position is below the reel 4, the counterweight 9 is installed on the hanger 1, corresponding to the position of the reducer 3, and used to balance the hanger shelf. There is a layer of rubber 5 on the surface of the reel 4 . In use, the sling fits onto the drum.

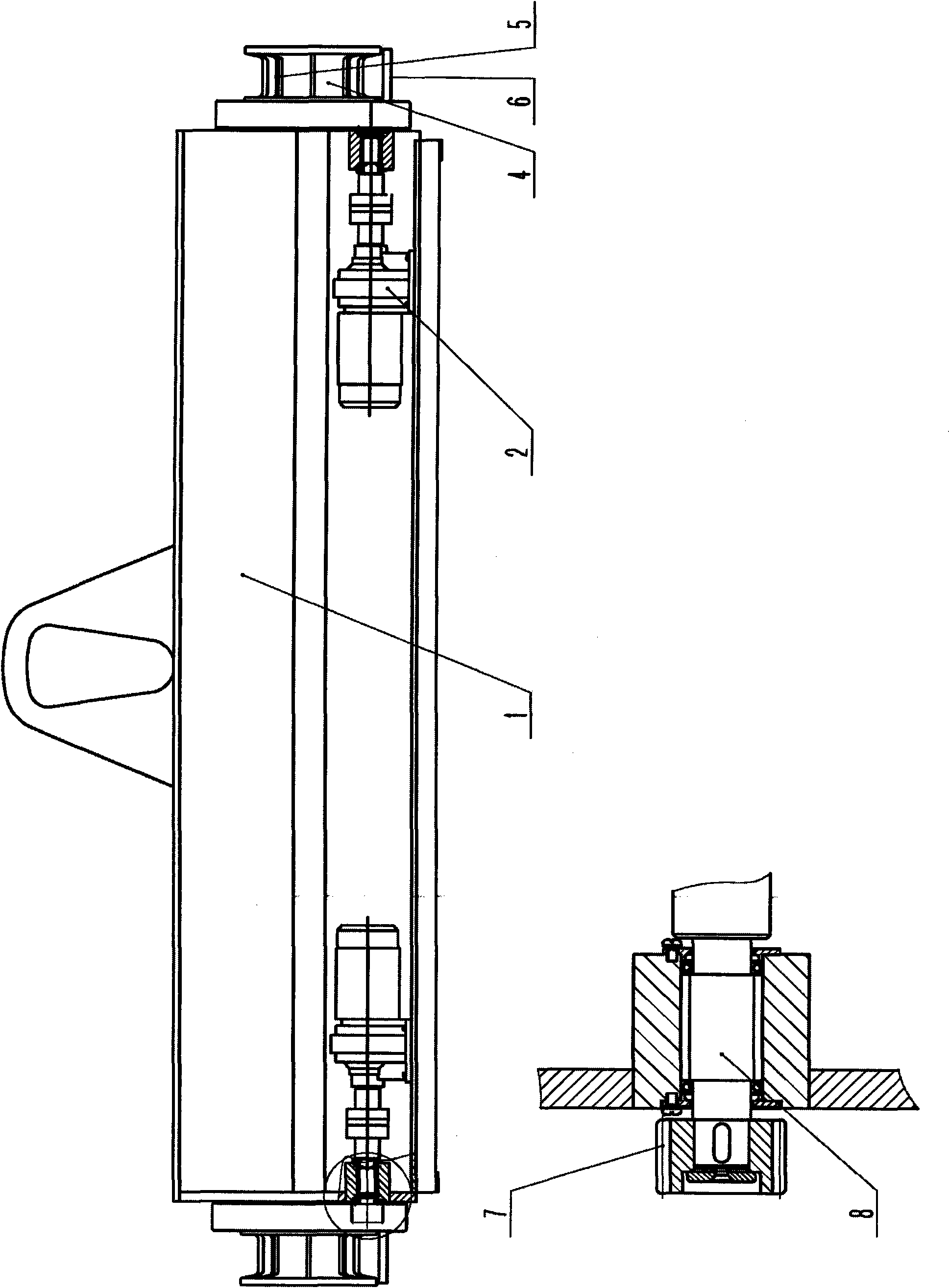

[0018] figure 2 What is shown is the structural diagram of the turning spreader when the number of reducers is 2 and the position of the reducer is fixed. The sling is not shown in this figure. figure 2 The turning spreader shown is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com