Steel plate adapting to large-linear energy welding and manufacturing method thereof

A large input energy welding and manufacturing method technology, applied in the field of iron and steel materials, can solve problems such as relatively difficult production, strict nitrogen content requirements, nozzle blockage, etc., and achieve the effects of excellent joint toughness, good low temperature toughness, and high joint toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

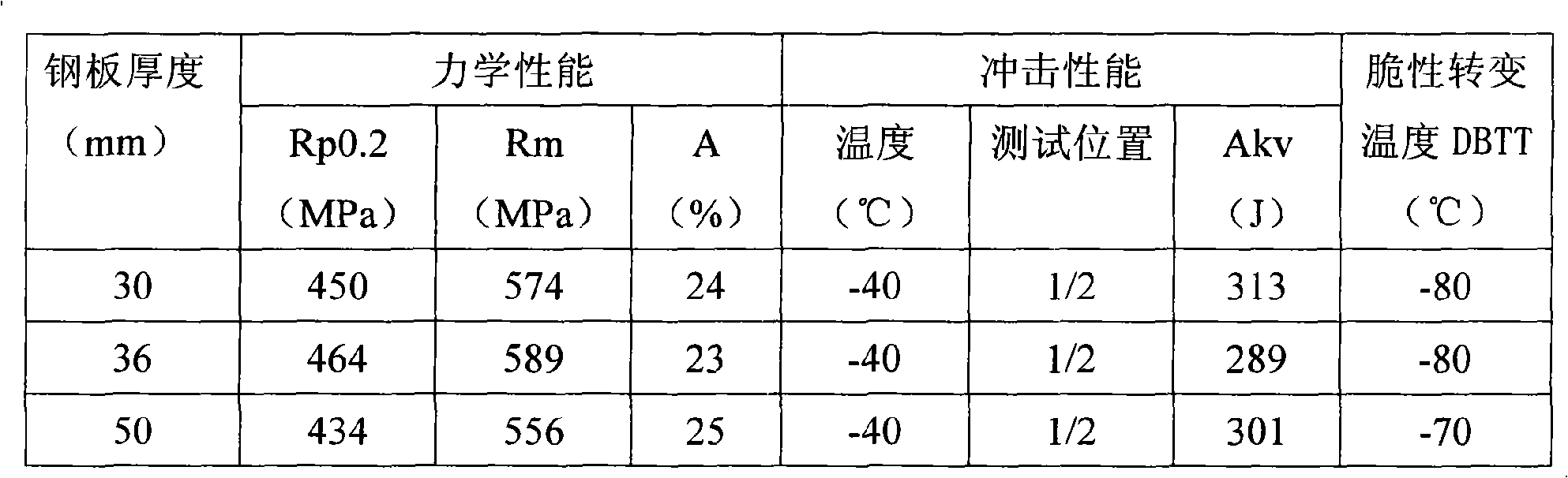

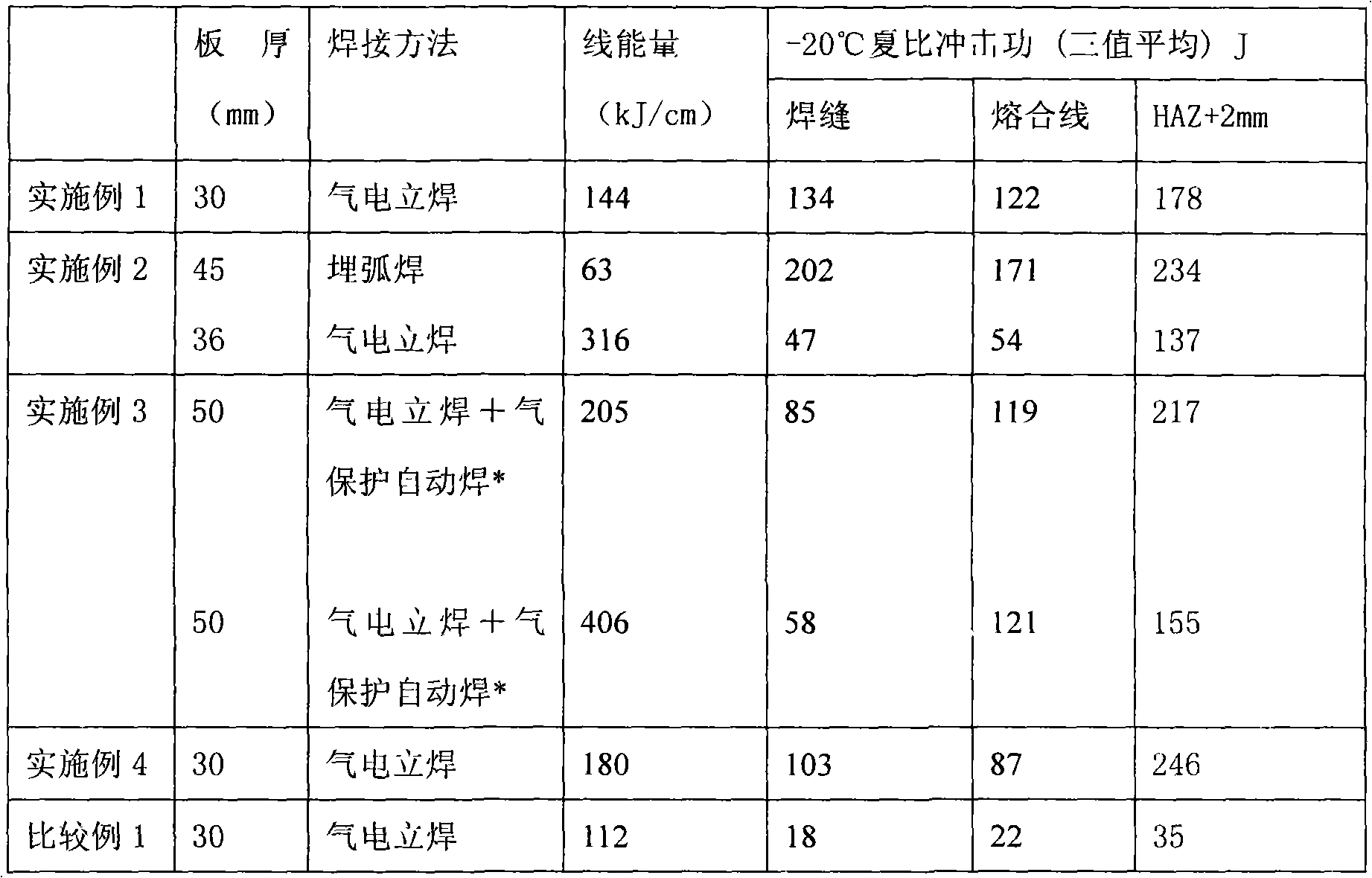

Embodiment 1

[0041] The molten steel is smelted according to the chemical composition shown in Table 1. The ladle top slag is reduced during the tapping stage of the converter, the oxygen level is controlled during the refining stage, and different deoxidizers are added in order to carry out deoxidation step by step. In the continuous casting process, the continuous casting slab will be subjected to strong cooling, and its smelting and continuous casting process conditions are shown in Table 2. The steel billet is heated to 1120°C before hot rolling, the rolling temperature in the recrystallization stage is higher than 960°C, the deformation of each pass is 15-35%, the rolling temperature in the non-recrystallization stage is 800°C, the cumulative deformation is ≥ 45%, and the final rolling temperature is 760 After rolling, wait until the temperature reaches 750°C, then water-cool to 550°C at 26°C / s, and then air-cool.

Embodiment 2

[0043] Except that the billet is heated to 1150°C before hot rolling, the rolling temperature is 780°C in the non-recrystallization stage, the final rolling temperature is 770°C, and the temperature is 760°C after rolling, and then water cooled to 450°C at 18°C / s. The rest of the implementation methods are the same example 1.

Embodiment 3

[0045] Except that the billet is heated to 1100°C before hot rolling, the rolling temperature is 820°C in the non-recrystallization stage, the final rolling temperature is 760°C, and the temperature is 760°C after rolling, and then water-cooled to 490°C at 30°C / s. The rest of the implementation methods are the same. example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com