Method and device for calibrating zero position output value of sensitive shaft of tilt angle sensor

A technology of inclination sensor and sensitive axis, applied in measuring devices, instruments, measuring inclination and other directions, can solve the problems of manually searching for sensitive axis errors, affecting the accuracy of zeroset, etc., to avoid errors, improve measurement accuracy, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

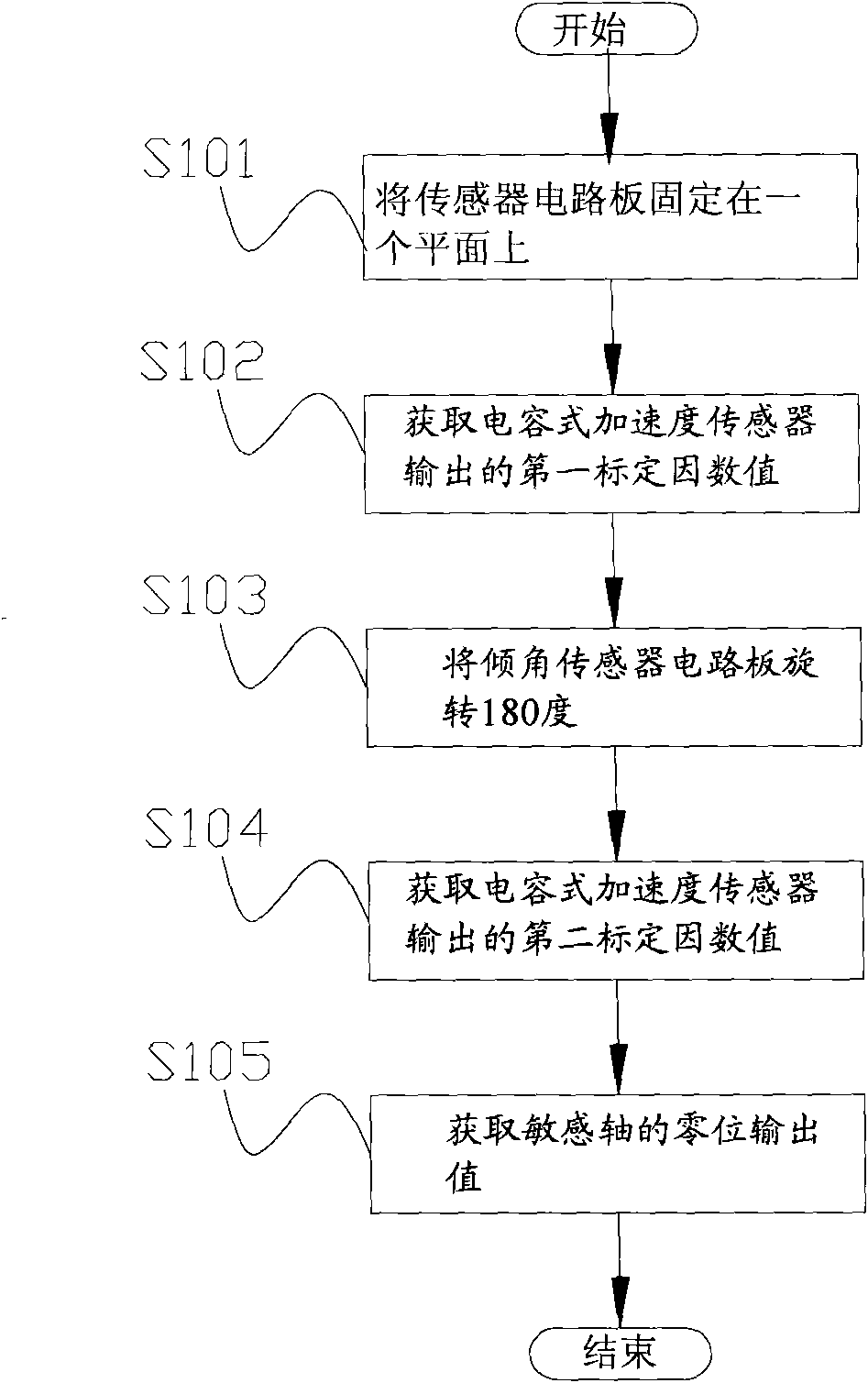

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

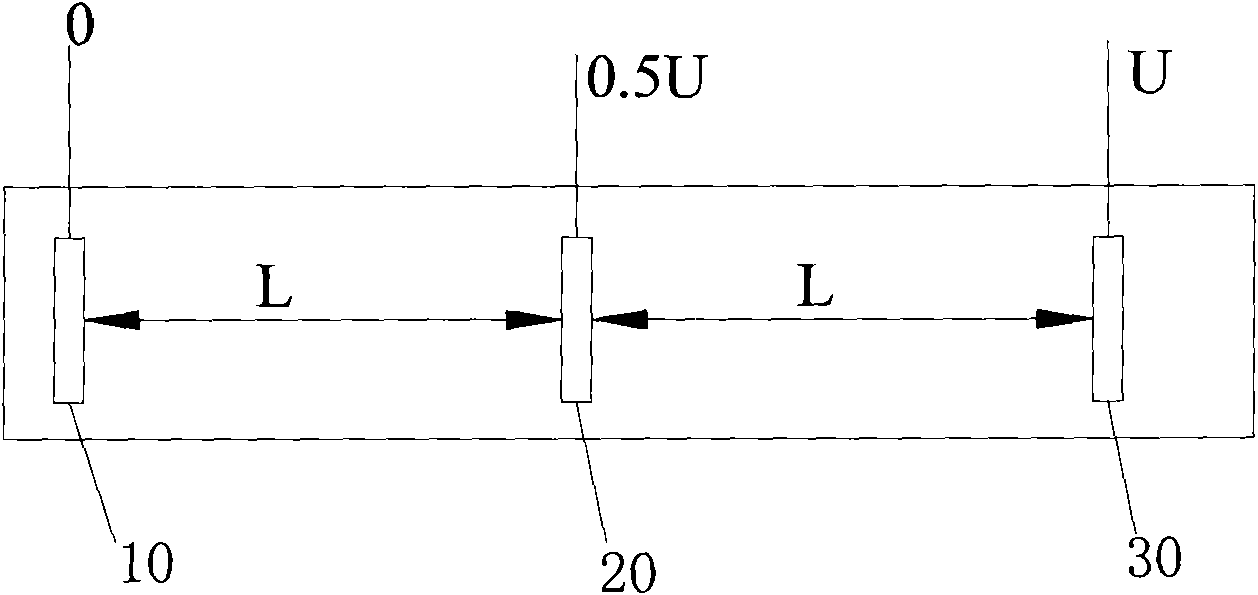

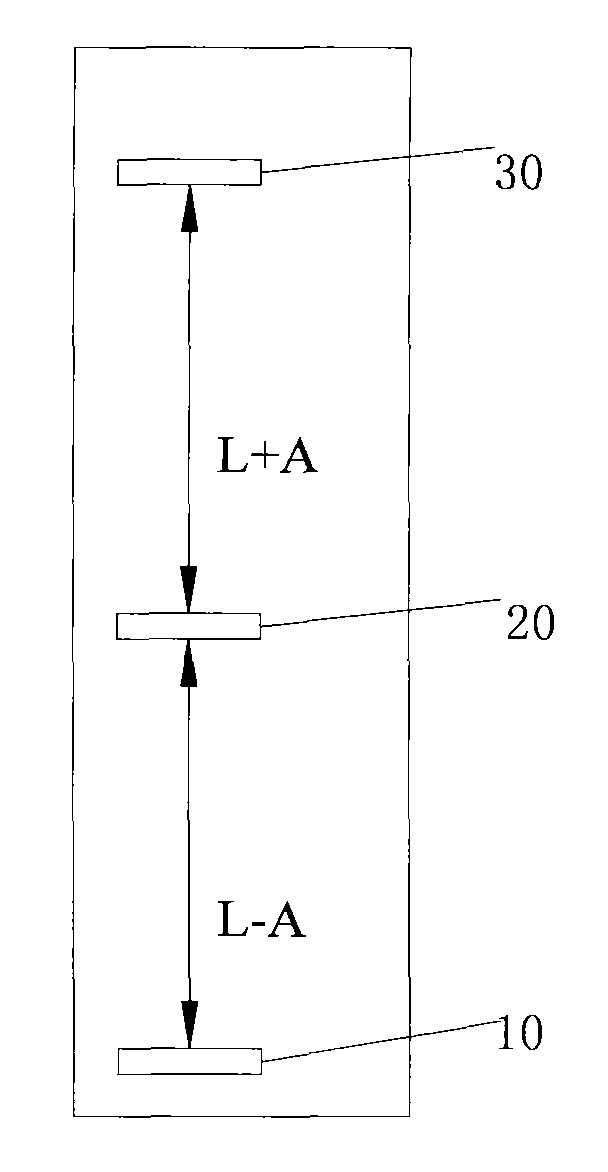

[0050] The inclination sensor can be provided with one sensitive axis, or two or more sensitive axes. For the convenience of description, the method for calibrating the zero output value of the sensitive axis of the inclination sensor provided in Embodiment 1 is described by taking an inclination sensor provided with an acceleration sensor with one sensitive axis as an example.

[0051] like figure 2 As shown, when starting to execute the method, it is necessary to start the calibration program module of the inclination sensor, that is, connect the corresponding circuit, obtain the corresponding initial parameters through the output terminal of the inclination sensor, or store the corresponding initial parameters i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com