Electrowetting type hybrid refractive-diffractive zooming liquid lens

A technology of refraction-diffraction mixing and liquid lens, which is applied in the fields of lenses, optics, instruments, etc. It can solve the problems of inability to optimize the aberration of a single-chip liquid lens and no degree of freedom in design, and achieve light weight, simple manufacturing, small volume and weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

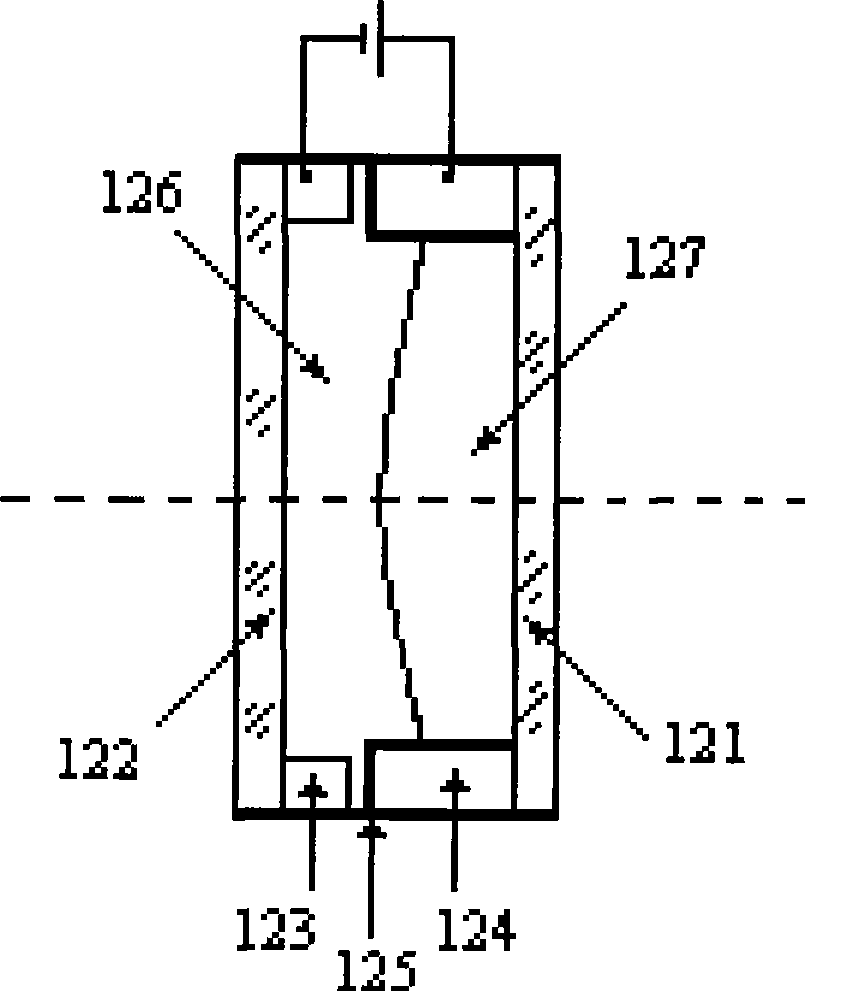

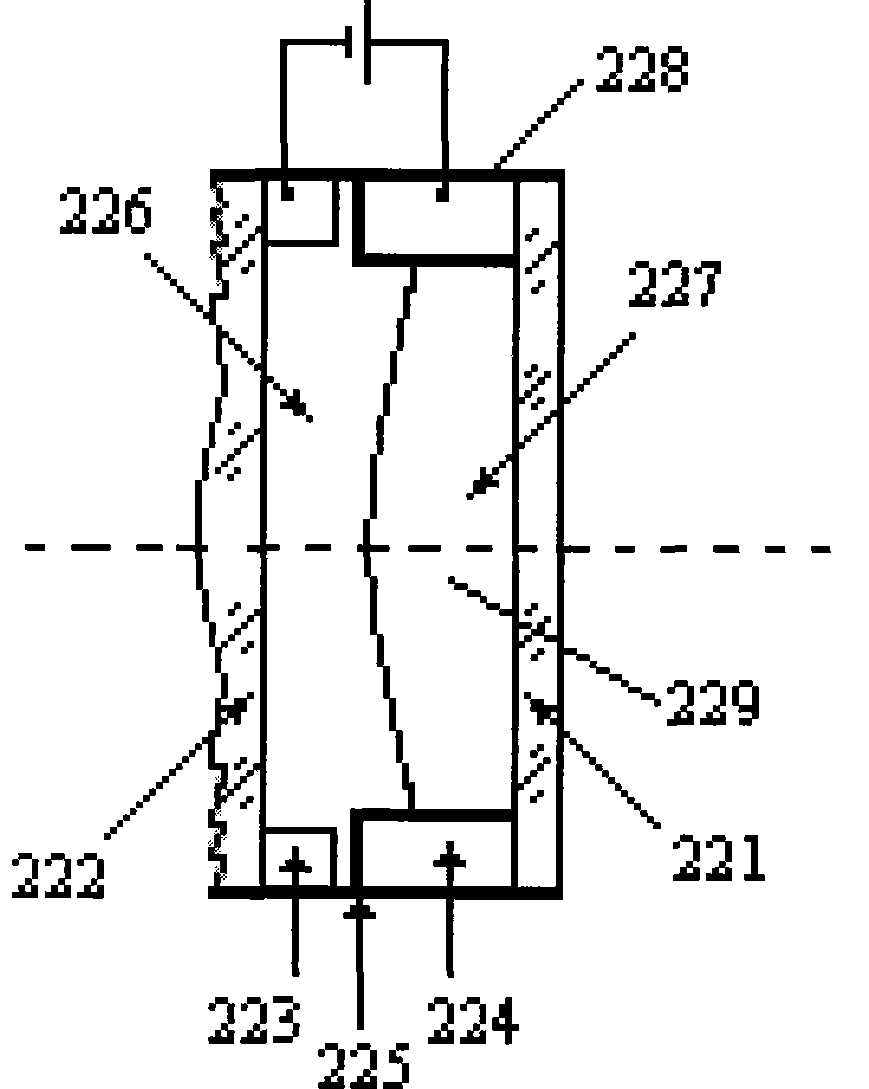

[0026] The present invention designs the ordinary flat glass substrate in the existing ordinary liquid lens as a diffractive optical element, that is, a diffractive surface substrate, and the diffractive surface substrate can be the first base glass plate 121 or the second base glass plate in the existing ordinary electrowetting liquid lens One of the base glass plates 122 , or the first base glass plate 121 and the second base glass plate 122 . The present invention adds a diffractive optical surface by using a diffractive optical element, that is, the phase function of the binary surface is introduced:

[0027] φ ( r ) = 2 π λ ( A 1 y 2 + A 2 y 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com