Liquefied natural gas carrier vessel, and marine transportation method for liquefied natural gas

A technology for liquefied natural gas and transport ships, which is applied in the directions of transportation and packaging, gas processing/storage purposes, ship accessories, etc., and can solve problems such as easy sloshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

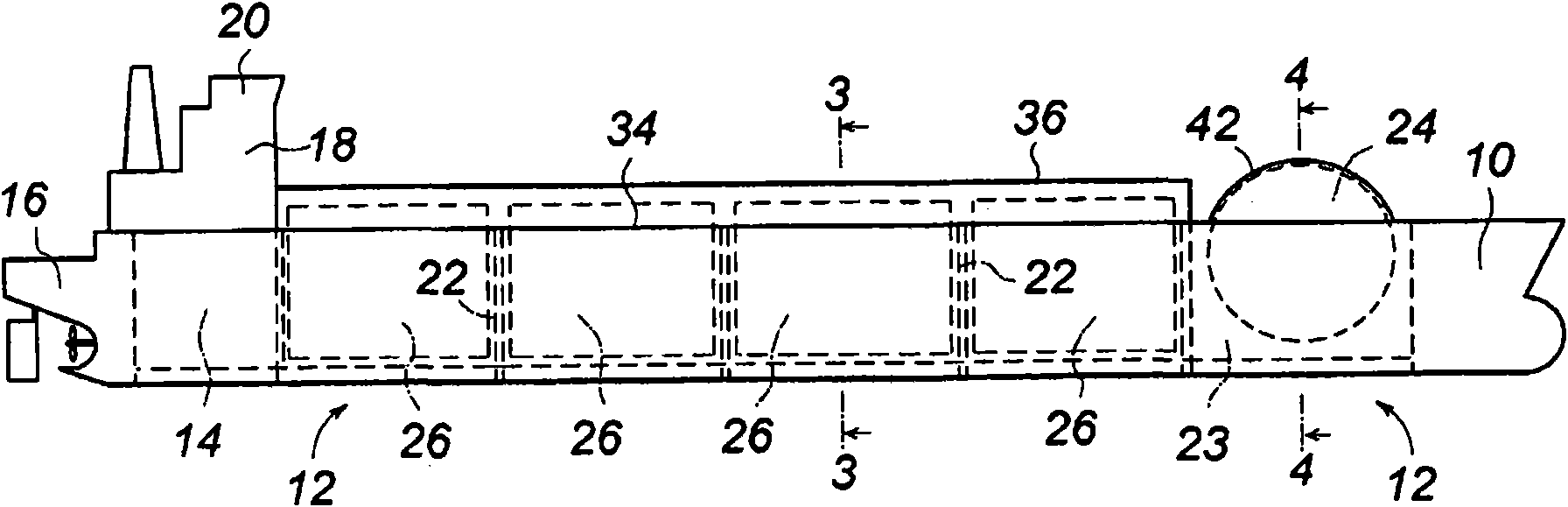

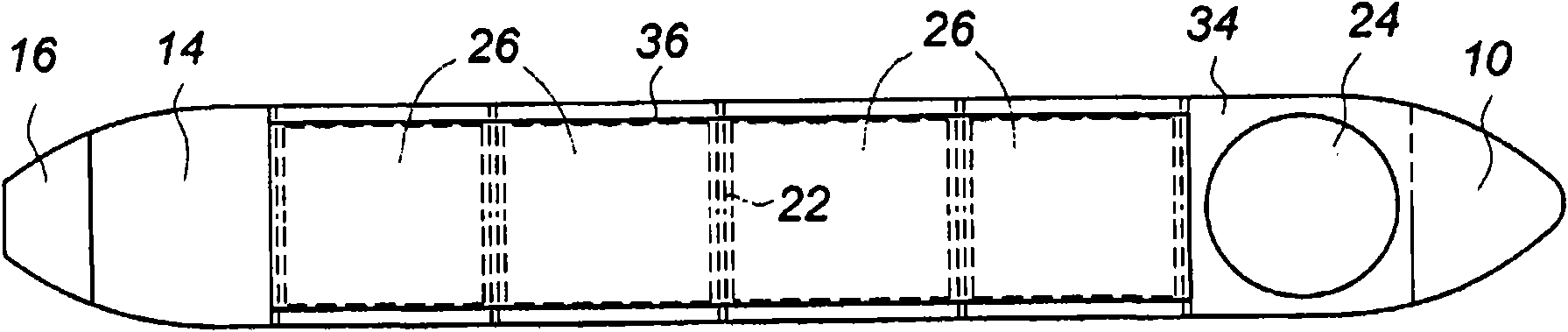

[0020] Such as figure 1 and figure 2 As shown, the LNG tanker is connected in sequence from the front to the bow 10 , the tank section 12 , the engine room 14 and the stern 16 , and the upper part of the engine room is provided with a living area 18 and then a wheelhouse 20 . The tank compartment 12 is divided into a plurality of compartments by transverse partitions 22, a spherical independent tank 24 is provided in the front compartment 23, and a diaphragm tank 26 is formed in the second to fifth compartments.

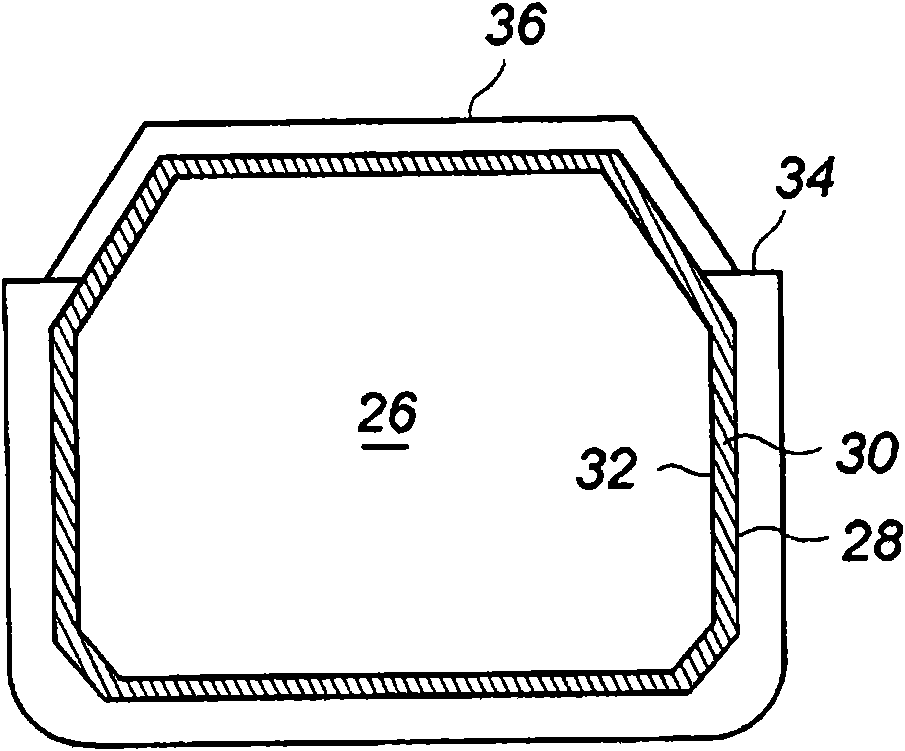

[0021] image 3 It is a cross-sectional view of a diaphragm tank. The hull has a two-layer hull structure at the bottom and side of the ship. By applying a heat-resistant layer 30 to the surface of these inner shells 28, the surface of the heat-resistant layer is covered with a diaphragm 32 in a liquid-tight manner. And the membrane type tank 26 is formed. In order to increase the tank capacity, the head of each diaphragm tank 26 protrudes upward through the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com