Method and device for dynamically determining a segment for an angular spread, inside which fuel is injected into an internal combustion engine

A technology of fuel injection, angle range, applied in the direction of fuel injection control, internal combustion piston engine, combustion engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

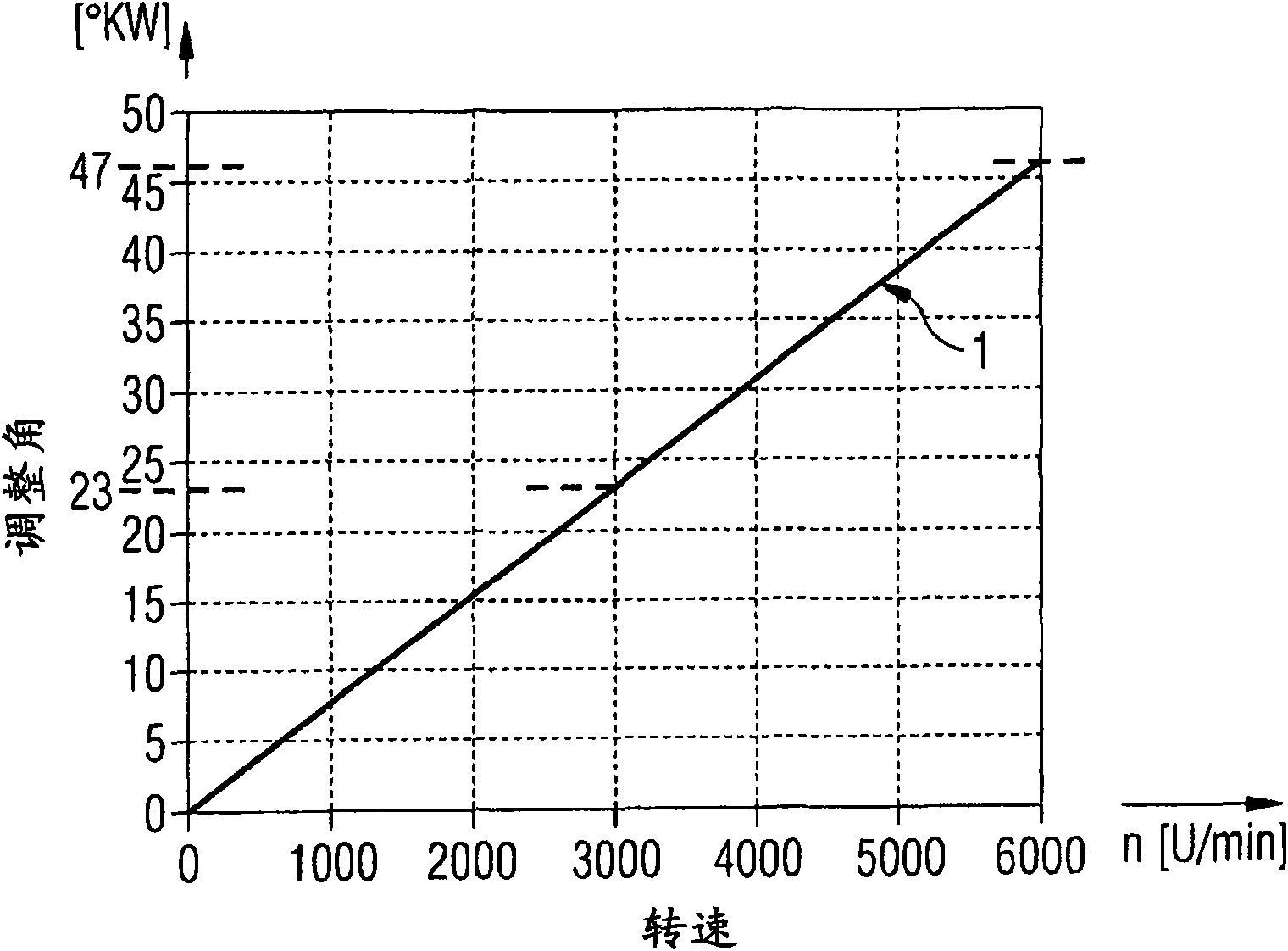

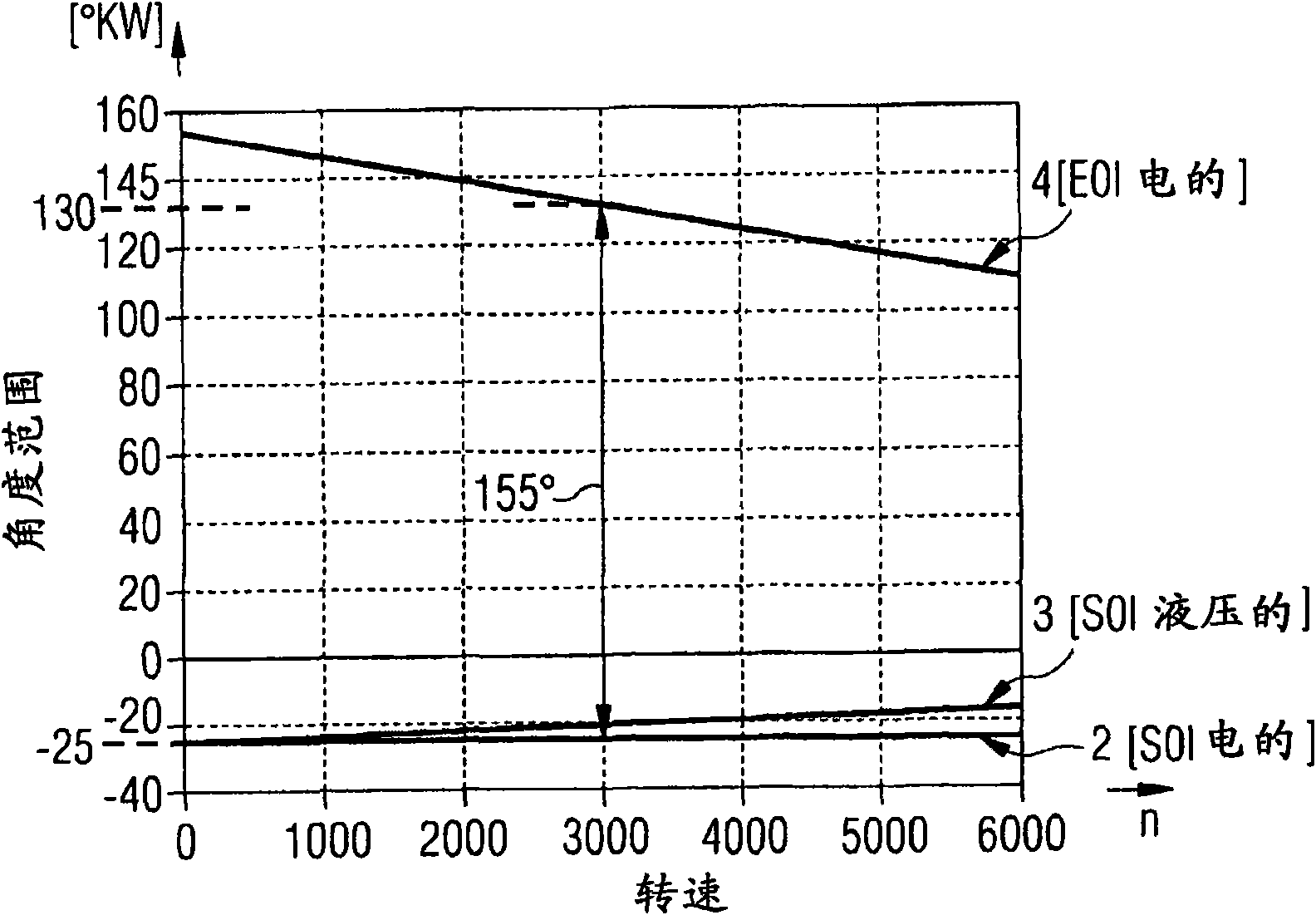

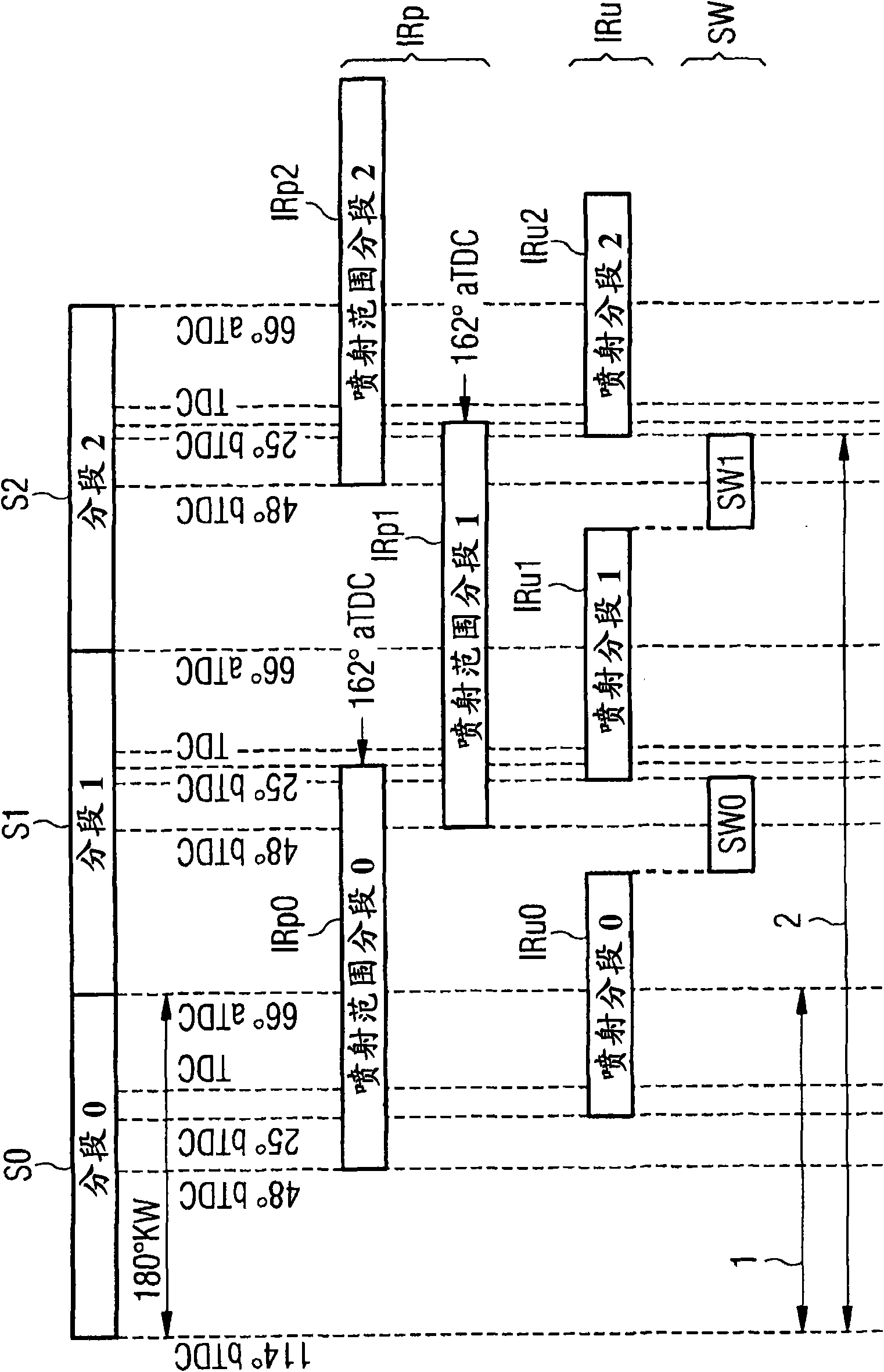

[0031] The invention mainly relates to the dynamic determination of the available injection range IRu of a segment S which is optimized in particular such that subsequent reinjections can be carried out for regeneration of the particle filter of a diesel engine, for example, without affecting the engine properties. A further essential aspect of the invention is that the available injection range IRu of the subsection S can be shifted in the retarding direction or vice versa in the advancing direction as required in its relative position as a function of the crankshaft angle. Next, the available injection range IRu is determined on the basis of the angular range and its relative position by means of the waiting time and the rotational speed gradient. The controller can thus calculate the maximum possible injection range IRu for each rotational speed n using a program designed for the stored algorithm or retrieve it from a table. It is thus possible to optimally use the availabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com