Fire head servo tracking device for edge-melting polishing machine

A tracking device and polishing machine technology, applied in the field of servo tracking devices, can solve the problems of increased production cost, waste of gas energy, heat energy, incomplete utilization of glass for flames, etc., and achieves convenient operation, improved flame utilization rate, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

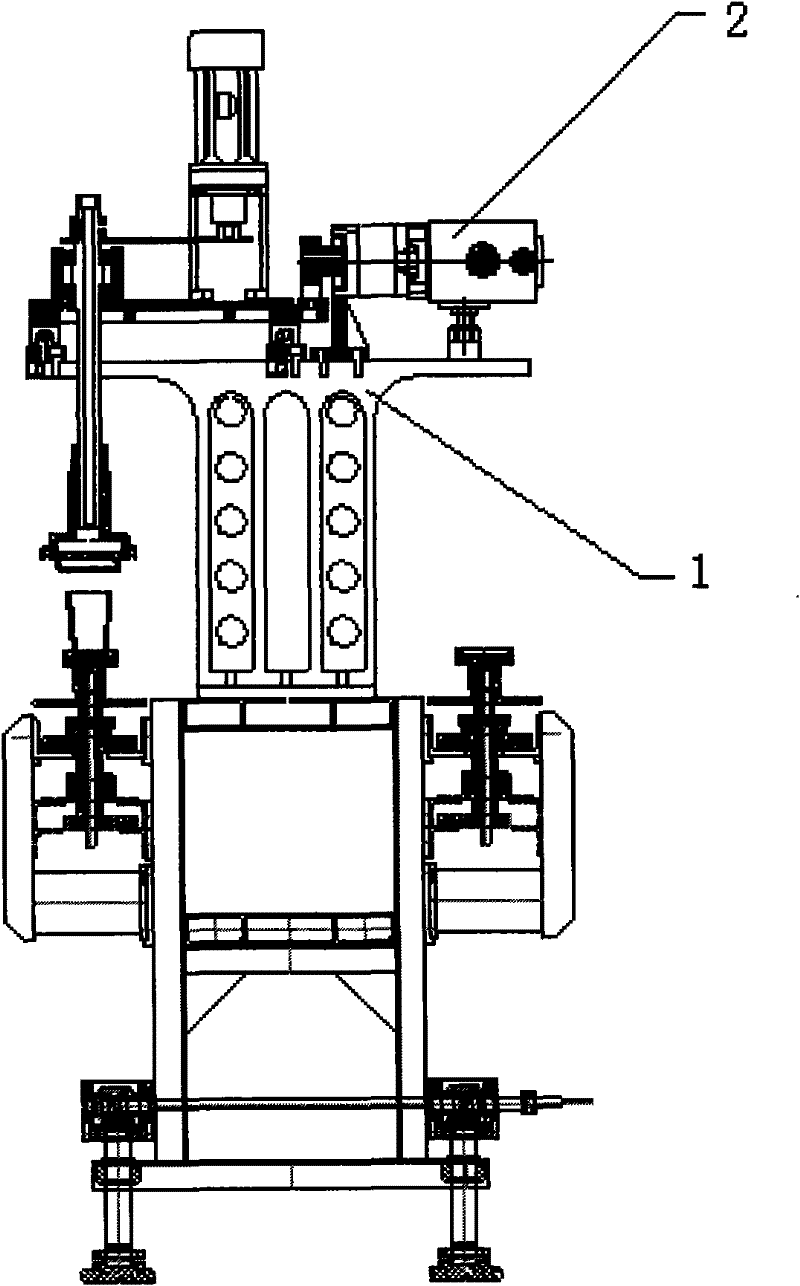

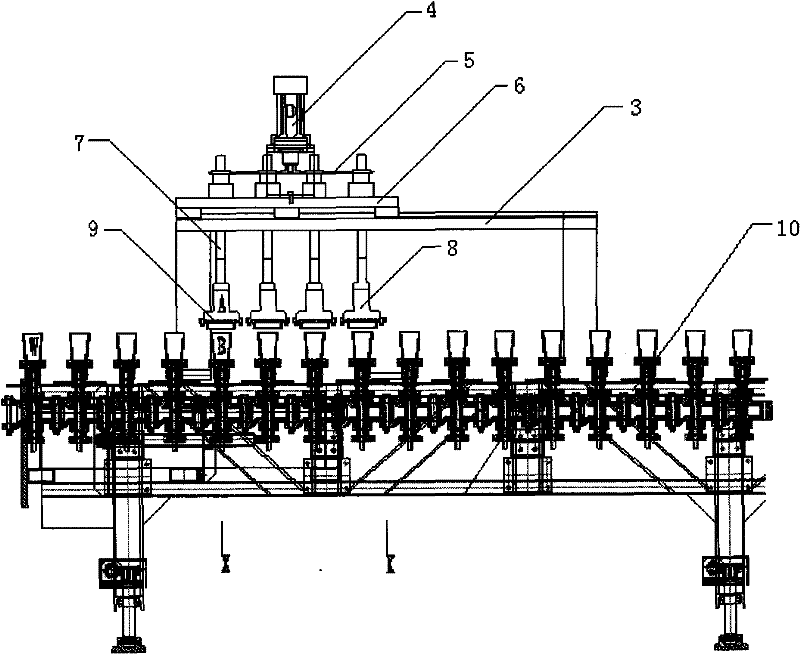

[0018] Such as figure 1 , figure 2 As shown, a burner servo tracking device for a mouth drying and polishing machine includes a body 1, a fire ring moving servo drive motor 2, a frame 3, a fire ring rotating motor 4, a chain 5, a moving frame 6, a flame spraying head 7, a flame spraying Ring 8, combustion disc 9, horizontal drying mouth polishing machine 10.

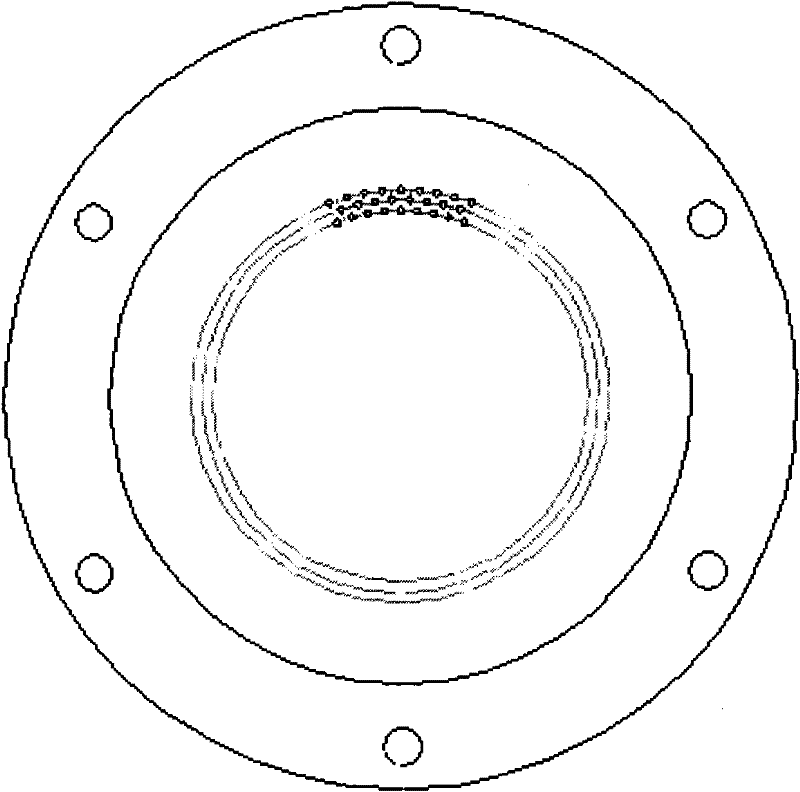

[0019] The fire ring moving servo drive motor 2 is fixed on the fuselage 1, the fire ring moving servo drive motor 2 drives the moving frame 6, and the moving speed and distance of the moving frame 6 are under the precise control of the servo drive motor 2 to drive the fire The ring 8 moves synchronously with the glass product; the fire ring rotating motor 4 is fixed on the moving frame 6, and drives the fire spraying head 7 to rotate through the chain 5, and there are four sets of the fire spraying head 7; the fire spraying head 7 is fixed on the moving frame 6, and the fire spraying ring 8 is installed at the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com