Tire procuring in-plastic-mat in large project and preparation method thereof

A large-scale project, pre-vulcanization technology, applied in the direction of adhesives, adhesive types, natural rubber adhesives, etc., can solve the problems of insufficient bonding strength, tire tread, insufficient bonding strength, etc., and achieve high tensile strength , Strong adhesion, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

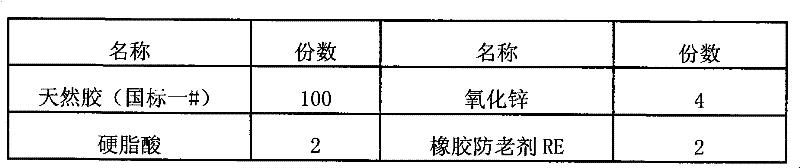

[0028] The pre-vulcanized middle cushion rubber of large-scale engineering tires is composed of raw materials according to parts by mass, natural rubber (GB 1#): 100 parts, zinc oxide: 3 parts, stearic acid: 1 part, rubber antioxidant RE: 1 part, Rubber antioxidant DFC-34: 1 part, rubber accelerator CZ: 0.4 parts, rubber accelerator M: 0.1 part, rubber accelerator TMTD: 0.1 part, carbon black N660: 10 parts, white carbon black: 10 parts, rubber oil : 2 parts, rubber adhesive A: 1 part, resorcinol: 1 part, C5 resin: 3 parts, rubber reinforcing agent QS-3: 2 parts, glue evenly dispersed or glue Yisu T78: 1 part, Sulfur: 1 part, rubber anti-scorch agent PVI: 0.1 part.

[0029] Jiaoyisu T78 is a carbon black dispersant produced by Qingdao Angji Rubber & Plastic Technology Co., Ltd. It can shorten the mixing time, improve the dispersion of carbon black and other powders in rubber, increase the extrusion speed, and stabilize the extrusion size. Lower extrusion temperature.

Embodiment 2

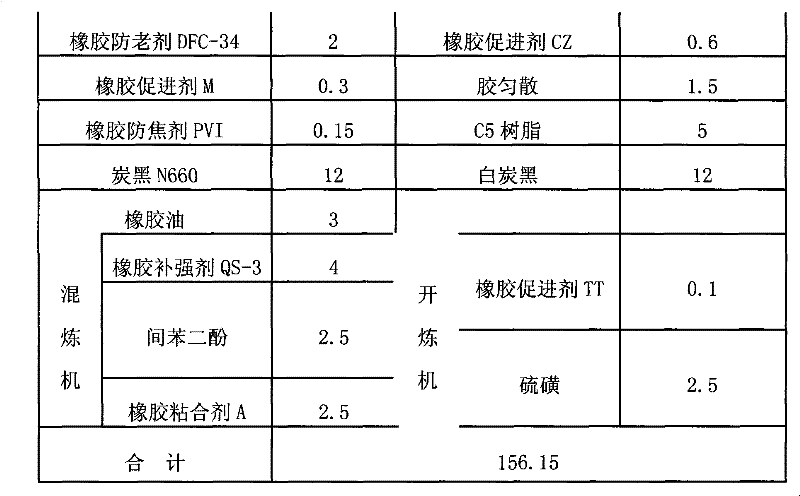

[0031] The pre-vulcanized middle cushion rubber of large-scale engineering tires is composed of raw materials according to parts by mass, natural rubber (GB 1#): 100 parts, zinc oxide: 4 parts, stearic acid: 2 parts, rubber antioxidant RE: 2 parts, Rubber antioxidant DFC-34: 2 parts, rubber accelerator CZ: 0.6 parts, rubber accelerator M: 0.3 parts, rubber accelerator TT: 1.5 parts, carbon black N660: 12 parts, white carbon black: 12 parts, rubber oil : 3 parts, rubber adhesive A: 2.5 parts, resorcinol: 2.5 parts, C5 resin: 5 parts, rubber reinforcing agent QS-3: 4 parts, glue evenly dispersed or Glue Yisu T78: 1.5 parts, Sulfur 2.5 parts, rubber anti-scorch agent PVI: 0.15 parts.

Embodiment 3

[0033] The pre-vulcanized middle cushion rubber of large-scale engineering tires is composed of raw materials according to parts by mass, natural rubber (GB 1#): 100 parts, zinc oxide: 5 parts, stearic acid: 3 parts, rubber antioxidant RE: 3 parts, Rubber antioxidant DFC-34: 3 parts, rubber accelerator CZ: 0.8 parts, rubber accelerator M: 0.4 parts, rubber accelerator TMTD: 0.4 parts, carbon black N660: 14 parts, white carbon black: 14 parts, rubber oil : 5 parts, rubber adhesive A: 4 parts, resorcinol: 4 parts, C5 resin: 7 parts, rubber reinforcing agent QS-3: 6 parts, glue evenly dispersed or glue Yisu T78: 3 parts, 4 parts of sulfur, rubber anti-scorch agent PVI: 0.2 parts.

[0034] The special method for the pre-vulcanized middle cushion rubber of the large-scale engineering tire of the above-mentioned embodiment comprises the following steps:

[0035] Step 1: put the natural rubber into the internal mixer, control the temperature to 70-80 degrees, the front and rear roto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com