Method for rolling industrial pure iron

A technology of industrial pure iron and rolls, applied in the rolling field of industrial pure iron, can solve the problems of high economic cost, unfavorable environmental protection concept, complex process and other problems, and achieve the effect of improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The first step is to use industrial pure iron to keep warm in the air at 900°C for 5 hours before asynchronous rolling, and then cool with the furnace to remove the surface oxide scale of the sample;

[0018] The second step is to use wire cutting to obtain the material to be rolled with a thickness of 20mm. Finally, the upper and lower rolls are used for asynchronous rolling.

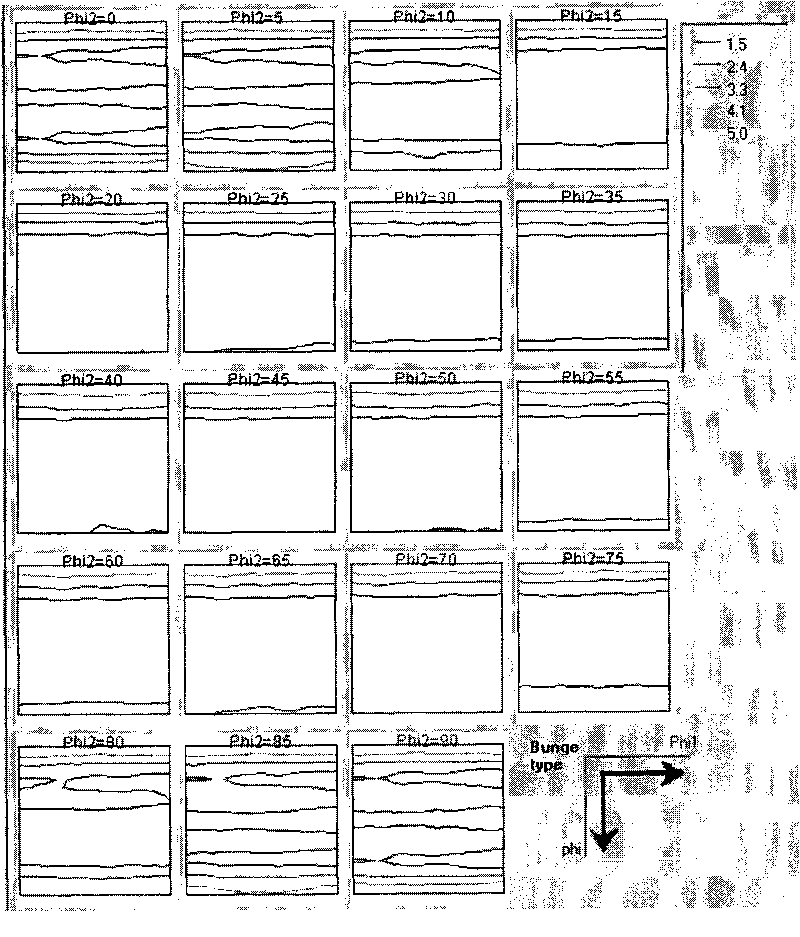

[0019] Multiple passes of cold rolling are adopted, and in this embodiment, the rolling reduction in each pass is 0.2 mm, and a total of 50 passes of rolling are performed. The final rolling reduction rate is 50%, and the final thickness of the sample is 10mm. Then adopt X-ray diffractometer to test its texture on the upper rolling surface of the sample, and the test results are as follows: figure 1 shown. The results show that the texture component of the sample is {100} texture.

Embodiment 2

[0021] The first step is to use industrial pure iron to keep warm in the air at 900°C for 5 hours before asynchronous rolling, and then cool with the furnace to remove the surface oxide scale of the sample;

[0022] The second step is to use wire cutting to obtain the material to be rolled with a thickness of 20mm. Finally, the upper and lower rolls are used for asynchronous rolling.

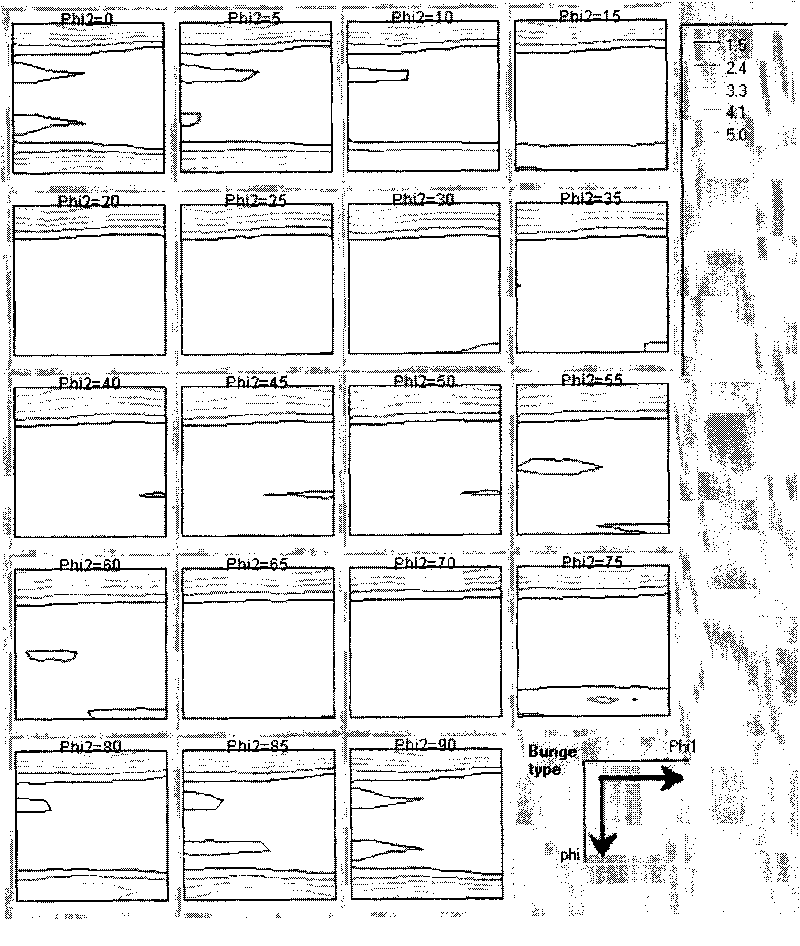

[0023] Multiple passes of cold rolling are adopted, and the rolling reduction in each pass is 0.2 mm in this embodiment, and 99 passes of rolling are performed in total. The final rolling reduction rate is 90%, and the final thickness of the sample is 2mm. Then adopt X-ray diffractometer to test its texture on the upper rolling surface of the sample, and the test results are as follows: figure 2 shown. The results show that the texture component of the sample is {100} texture, and its strength is greater than that of industrial pure iron with a rolling reduction rate of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com