Automatic level with built-in micrometer panel and assembly method thereof

An automatic leveling and leveling technology, used in instruments, measuring devices, surveying and mapping, and navigation, etc., can solve the problems that the instruments are not stable enough, affect the measurement accuracy, and affect the micrometric accuracy, and achieve short instrument adjustment time and wide temperature range. , observe the effect of clear target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

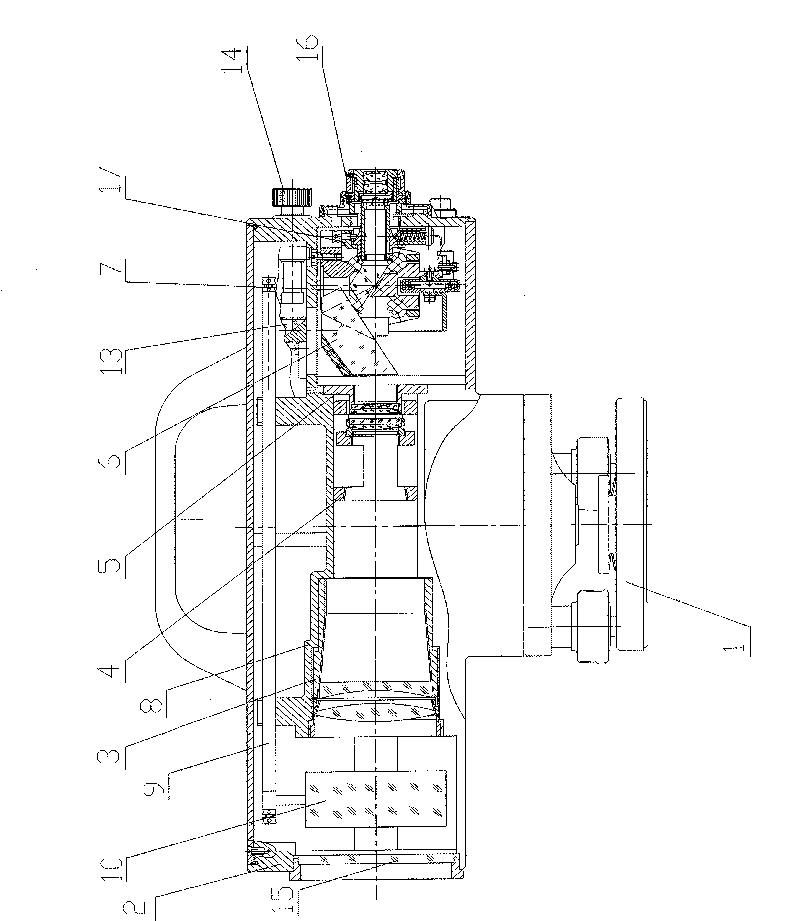

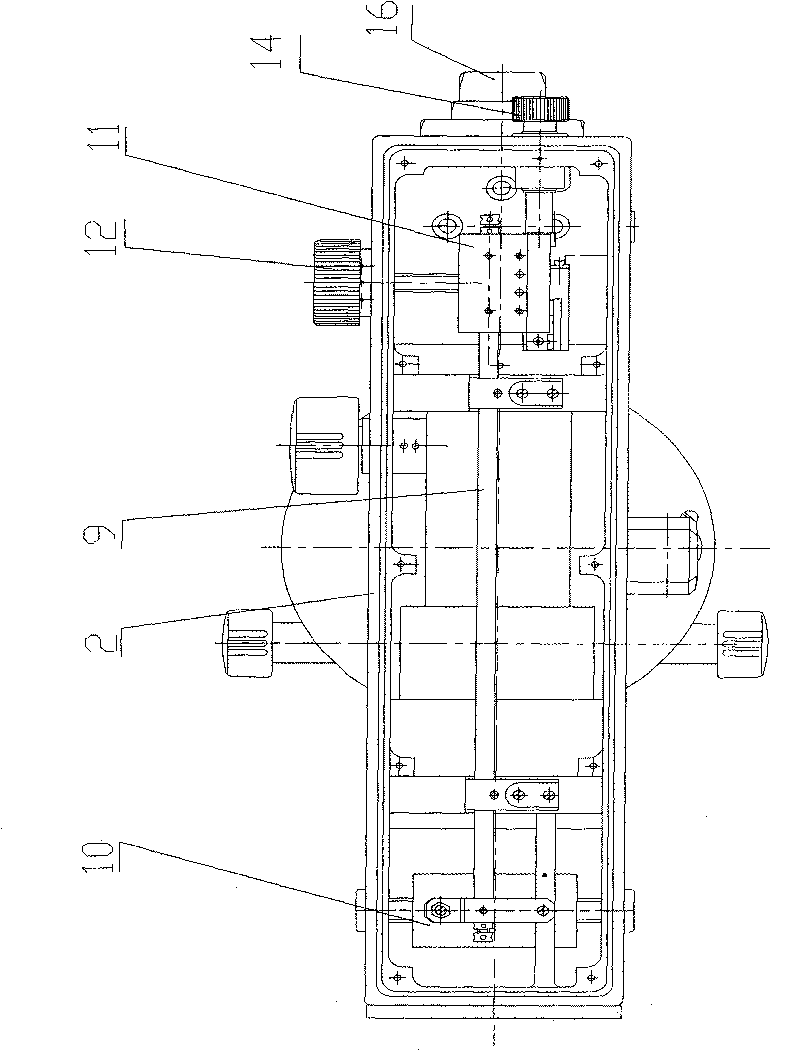

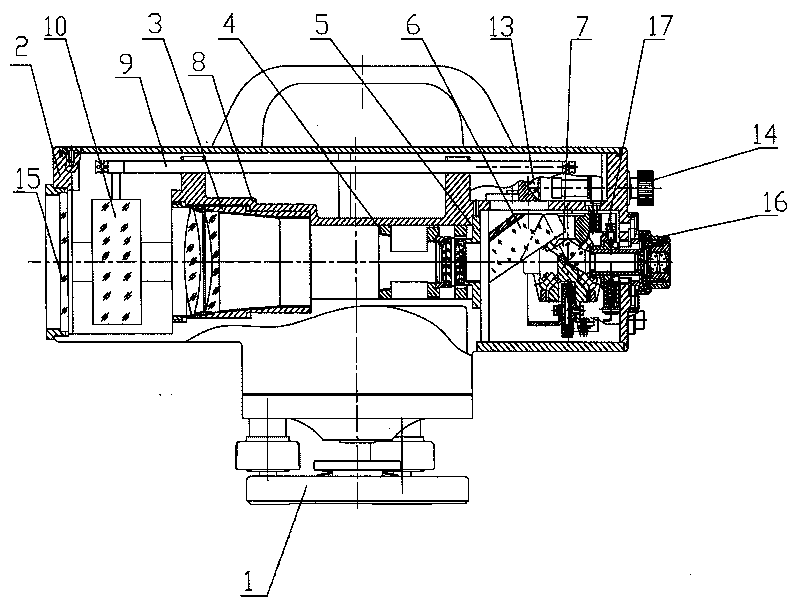

[0013] Give a preferred embodiment below and in conjunction with drawing, the present invention is described in detail as follows, refer to figure 1 , figure 2 :

[0014] The base 1 is equipped with components such as a vertical shaft, a dial, an leveling screw group, and a garden level. The structure of these components is the same as that of the dsz2 type automatic leveling level. Therefore, the specific structure of the base is not discussed here. repeat;

[0015] A horizontally arranged rotatable level housing 2 is installed on the base 1, and the housing 2 includes a detachable upper and lower cover plate; the main objective lens group 3 and the focusing mirror are sequentially installed in the housing 2 along the horizontal direction. Group 4, rear objective lens group 5, erecting prism group 6, compensator 7, reticle group 17 and other components; wherein: the objective lens pressure ring is located at the front peripheral wall of the main objective lens group 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com